All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

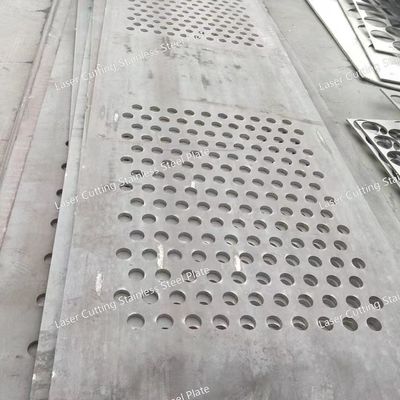

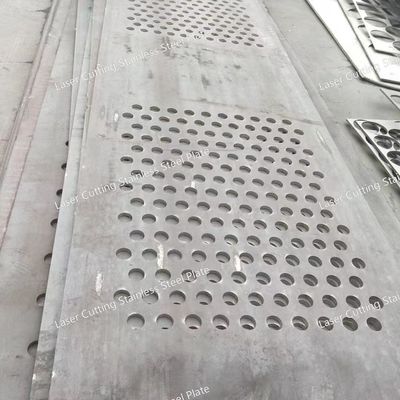

Laser Cutting AISI310S / 1.4845 / S31008 Stainless Steel Plate Sheet Heat Resistant SS Plates

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 304 304L 316L 310S 321 2205 2507 904L 254SMO.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 5000 - 7200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Product Details

| Products | Stainless Steel Plate | Grade | 304 304L 316L 310S 321 2205 2507 904L 254SMO.etc |

|---|---|---|---|

| Thickness | 0.6 - 30.0mm | Width | 1219mm 1500mm 1800mm 2000mm |

| Surface | NO.1 2B | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | 1.4845 Stainless Steel Sheet,AISI310S Stainless Steel Sheet,Laser Cutting S31008 Stainless Steel Sheet |

||

Product Description

Laser Cutting AISI310S / 1.4845 / S31008 Stainless Steel Plate Sheet Heat Resistant SS Plates

Products Specification

| Products Name | Laser Cutting Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 317L, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,654SMO,253MA,2205,2507.etc |

| Thickness | 0.6 - 30.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Service | Laser Cutting |

| Form | Plate / sheet |

| Cutting Shape | Round , Square, or any special shape as request |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

1. Overview of 310S Stainless Steel Plates

1.1 Key Parameters

1.2 Common Sizes

1.3 Standards

1.4 Key Characteristics

1.5 Applications

2. Laser Cutting of 310S Stainless Steel Plates

2.1 Advantages of Laser Cutting

2.2 Processing Range

![]()

![]()

![]()

![]()

Recommended Products