Tutti i prodotti

-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

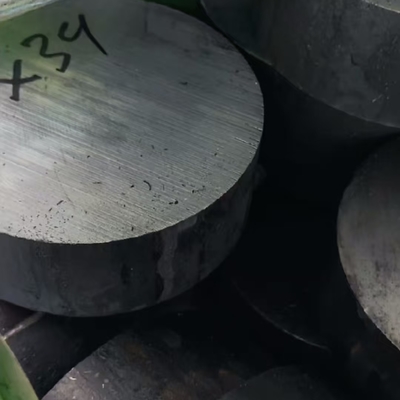

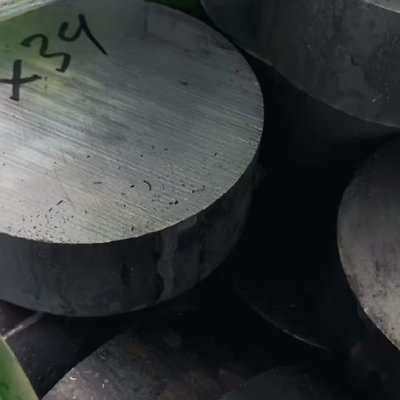

Applicazione in area chimica Barra tonda in lega di nichel C276 / Albero brillante Diametro 6 - 300mm Taglio personalizzato a misura

| Luogo di origine | Cina |

|---|---|

| Marca | DELTA |

| Certificazione | ISO |

| Numero di modello | c276 |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 40-45 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 3 tonnellate a settimana |

Dettagli

| Prodotti | Placca in lega di nichel | Grado | c276 |

|---|---|---|---|

| Diametro | 6 - 350 mm | Lunghezza | taglio su misura di qualsiasi lunghezza su richiesta |

| Standard | Astm en | Servizio | Taglio |

| Porta di caricamento | Shanghai Port | Superficie | nero, luminoso |

| Evidenziare | Nickel Alloy C276 round bar,Bright shaft C276 alloy,Custom cut C276 nickel bar |

||

Descrizione di prodotto

Applicazione nell'area chimica Barra tonda in lega di nichel C276 / Albero lucido Diametro 6 - 300 mm Taglio personalizzato a misura

Informazioni rapide

| Grado | Hastelloy C276 / 2.4819 | Forma | Barra tonda |

| Diametro | 6.0 - 350mm | Tipo | Laminato a caldo, forgiato |

| Lunghezza | Taglio personalizzato a qualsiasi lunghezza su richiesta | Certificato | EN 10204-3.1 |

Maggiori informazioni sulle specifiche

| Nome dei prodotti | Barra tonda / Asta Hastelloy C276 |

| Diametro | 6.0 - 350mm |

| Lunghezza | taglio personalizzato a qualsiasi lunghezza su richiesta |

| Superficie | Nero, lucido |

| Marchio | DELTA |

| Servizio | taglio |

| MOQ | 2 Kg |

| Altro tipo | barra tonda, nastro, bobina, tubo, lamiera, piastra, filo, ecc. |

| Imballaggio | carta impermeabile e pallet di legno, scatola di legno |

| Porto di carico | Porto di Shanghai |

| Termine di prezzo | EXW, FOB, CIF, CFR |

| Tempo di consegna | entro 12 giorni |

Applicazione nell'area chimica Barra tonda in lega di nichel C276 / Albero lucido Diametro 6 - 300 mm Taglio personalizzato a misura

La barra tonda in lega di nichel C276 (nota anche come albero lucido quando rifinita con una superficie ad alta lucentezza) è un materiale strutturale resistente alla corrosione di alta qualità progettato per ambienti chimici estremi. Con un intervallo di diametro di 6–300 mm e taglio a misura personalizzabile, offre prestazioni eccezionali in scenari in cui la maggior parte dei metalli fallisce, rendendolo un materiale fondamentale nella lavorazione chimica, nella petrolchimica e in altri settori industriali aggressivi. Di seguito è riportata una ripartizione dettagliata dei suoi parametri, proprietà, processi di fabbricazione, standard, gradi equivalenti e applicazioni.

1. Specifiche principali (Parametri)

Le dimensioni e la composizione chimica della barra tonda C276 sono rigorosamente controllate per garantire coerenza e affidabilità, in particolare per applicazioni chimiche critiche.

| Categoria | Dettagli |

|---|---|

| Dimensioni | - Diametro: 6 mm – 300 mm (copre da piccole parti di precisione a grandi componenti strutturali) - Lunghezza: taglio personalizzato disponibile (intervalli comuni: 100 mm – 6000 mm; su misura in base ai disegni del cliente o alle esigenze di assemblaggio) - Finitura superficiale: albero lucido (Ra ≤ 0,8μm, ottenuto tramite rettifica/lucidatura di precisione) o finitura ossidata nera (per la protezione dalla ruggine durante lo stoccaggio) |

| Composizione chimica (%) | - Nichel (Ni): 57 min (elemento base, garantisce resistenza alla corrosione e duttilità) - Cromo (Cr): 14,5 – 16,5 (migliora la resistenza all'ossidazione e alla vaiolatura) - Molibdeno (Mo): 15,0 – 17,0 (fondamentale per la resistenza alla criccatura da corrosione sotto tensione indotta da cloruri) - Tungsteno (W): 3,0 – 4,5 (aumenta la resistenza alla vaiolatura e alla corrosione interstiziale) - Ferro (Fe): 4,0 – 7,0 (migliora la lavorabilità senza compromettere le prestazioni di corrosione) - Carbonio (C): 0,01 max (minimizza la precipitazione di carburi, prevenendo la corrosione intergranulare) - Silicio (Si): 0,08 max, Manganese (Mn): 1,0 max (elementi in traccia per la lavorabilità) |

| Proprietà meccaniche (stato ricotto) | - Resistenza alla trazione: ≥ 690 MPa - Limite di snervamento (0,2% Offset): ≥ 275 MPa - Allungamento (in 50 mm): ≥ 40% - Durezza: ≤ 210 HB (Brinell) o ≤ 220 HV (Vickers) |

2. Caratteristiche prestazionali chiave

Le prestazioni della barra tonda C276 sono definite dalla sua impareggiabile resistenza alla corrosione e dalle proprietà meccaniche equilibrate, che la rendono adatta ad ambienti chimici aggressivi:

2.1 Eccezionale resistenza alla corrosione

- Ampia tolleranza chimica: resiste alla maggior parte degli acidi organici (ad es. acido acetico, acido formico), acidi inorganici (ad es. acido solforico, acido cloridrico fino al 50% di concentrazione), alcali e soluzioni saline (ad es. acqua di mare, salamoie). È una delle poche leghe che resiste al gas cloro umido e ai mezzi ricchi di cloruri (una delle principali cause di criccatura da corrosione sotto tensione negli acciai inossidabili).

- Nessuna corrosione intergranulare: il basso contenuto di carbonio (≤0,01%) e la lega controllata prevengono la precipitazione di carburi durante la saldatura o il trattamento termico, eliminando i rischi di corrosione intergranulare nei reattori chimici.

2.2 Stabilità meccanica e termica

- Duttilità e tenacità: mantiene un elevato allungamento (≥40%) anche a temperature criogeniche (-270°C), rendendolo adatto allo stoccaggio chimico a bassa temperatura. A temperature elevate (fino a 1093°C), mantiene una resistenza sufficiente per le apparecchiature di lavorazione ad alta temperatura.

- Saldabilità: compatibile con i metodi di saldatura comuni (TIG, MIG, SMAW) senza preriscaldamento o trattamento termico post-saldatura (PWHT), riducendo la complessità della produzione per grandi recipienti chimici.

2.3 Prestazioni superficiali (Vantaggio dell'albero lucido)

La finitura dell'albero lucido (Ra ≤ 0,8μm) offre due vantaggi fondamentali per le applicazioni chimiche:

- Minimizza la formazione di fessure (dove spesso inizia la corrosione) sulla superficie della barra.

- Garantisce un flusso regolare del materiale nei componenti di movimentazione dei fluidi (ad es. valvole, pompe), riducendo l'attrito e l'accumulo chimico.

3. Processo di fabbricazione

La produzione della barra tonda C276 segue rigorosi controlli di qualità per soddisfare gli standard dell'industria chimica, con passaggi chiave tra cui:

-

Fusione e colata della lega:

- Le materie prime (Ni, Cr, Mo, W ad alta purezza) vengono fuse in un forno ad arco elettrico (EAF) o in una fusione a induzione sottovuoto (VIM) per evitare la contaminazione da impurità.

- La lega fusa viene colata in lingotti cilindrici (dimensioni corrispondenti al diametro finale della barra) per garantire una struttura uniforme del grano.

-

Forgiatura e laminazione a caldo:

- I lingotti vengono riscaldati a 1150–1200°C e forgiati in grezzi tondi grezzi, rompendo i grani grossolani e migliorando le proprietà meccaniche.

- I grezzi vengono quindi laminati a caldo al diametro desiderato (6–300 mm) tramite laminatoi a passaggi multipli, garantendo l'accuratezza dimensionale.

-

Trattamento termico:

- Ricottura: eseguita a 1120–1150°C per 30–60 minuti, seguita da tempra rapida in acqua. Questo passaggio ammorbidisce il materiale (riducendo la durezza a ≤210 HB) ed elimina le sollecitazioni interne, fondamentali per la successiva lavorazione.

-

Lavorazione di precisione e finitura superficiale:

- Per alberi lucidi: trafilatura a freddo (per affinare la tolleranza del diametro) seguita da rettifica senza centri e lucidatura per ottenere una rugosità superficiale Ra ≤ 0,8μm.

- Taglio personalizzato: seghe CNC o macchine per il taglio laser vengono utilizzate per tagliare le barre alle lunghezze specificate dal cliente (tolleranza: ±0,5 mm per lunghezze ≤1000 mm), garantendo la compatibilità con i requisiti di assemblaggio.

-

Controllo di qualità:

- Test di composizione chimica (tramite 光谱分析 /spettroscopia di emissione ottica, OES).

- Test delle proprietà meccaniche (test di trazione, durezza, impatto).

- Ispezione dimensionale (utilizzando calibri, micrometri o scanner laser).

- Verifica della resistenza alla corrosione (test allo spruzzo salino o test di immersione in ambienti chimici simulati).

4. Standard di settore

La barra tonda C276 è conforme agli standard globali per garantire l'intercambiabilità e le prestazioni nei progetti chimici internazionali:

| Organizzazione standard | Standard pertinenti |

|---|---|

| ASTM International (USA) | - ASTM B574: specifica standard per leghe di nichel-cromo-molibdeno-niobio (UNS N10276) Rod, Bar e Wire - ASTM B622: specifica standard per leghe di nichel-cromo-molibdeno (UNS N10276) Plate, Sheet e Strip (riferimento per la consistenza della lega) |

| ASME (USA) | - ASME SB574: Boiler and Pressure Vessel Code (BPVC) 认可 standard per la barra C276 (fondamentale per i componenti contenenti pressione nei reattori chimici) |

| DIN (Germania) | - DIN 17750: prodotti semilavorati in nichel e leghe di nichel (copre le dimensioni e le proprietà della barra C276) |

| JIS (Giappone) | - JIS H4553: leghe di nichel per recipienti a pressione e tubazioni (include gradi equivalenti C276) |

| ISO (Internazionale) | - ISO 9723: nichel e leghe di nichel – barre e barre (specifica generale per la barra C276) |

5. 相近牌号 (Gradi equivalenti)

C276 è registrato con il UNS (Unified Numbering System) come N10276. I suoi equivalenti internazionali sono:

| Paese/Regione | Standard | Grado/Designazione |

|---|---|---|

| USA | ASTM/ASME | N10276 (C276) |

| Germania | DIN | 2.4819 |

| Giappone | JIS | NW276 |

| Francia | AFNOR | NC17D |

| Cina | GB/T | NS3306 |

| Internazionale | ISO | NiCr16Mo16W4 |

6. Applicazione nelle industrie chimiche e correlate

La resistenza alla corrosione e le dimensioni personalizzabili della barra tonda C276 la rendono ideale per componenti critici nella lavorazione chimica e in ambienti aggressivi:

6.1 Applicazioni principali dell'industria chimica

- Reattori e recipienti chimici: utilizzati per alberi interni, aste agitatrici e strutture di supporto in reattori che trattano acido solforico, acido cloridrico o solventi clorurati.

- Componenti per la movimentazione dei fluidi: lavorati in valvole, alberi di pompe e raccordi per sistemi di trasferimento chimico (resiste all'erosione-corrosione da fluidi ad alta velocità).

- Scambiatori di calore: impiegati come piastre tubiere o barre deflettrici negli scambiatori di calore per il recupero degli acidi (resiste ai cicli di temperatura e ai refrigeranti acidi).

6.2 Usi industriali estesi

- Petrolchimici: componenti per piattaforme petrolifere offshore (resistenza all'acqua di mare) e raffinerie (gestisce derivati del petrolio greggio e solfuro di idrogeno).

- Prodotti farmaceutici: alberi lucidi sanitari per apparecchiature di miscelazione (la superficie liscia previene l'accumulo batterico ed è conforme agli standard FDA).

- Trattamento delle acque reflue: barre per alberi di aeratori e pompe per fanghi in impianti di trattamento delle acque reflue industriali (resiste agli effluenti corrosivi come i sali di metalli pesanti).

![]()

![]()

![]()

![]()

Prodotti raccomandati