Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

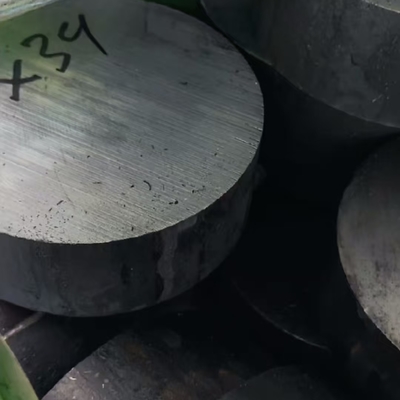

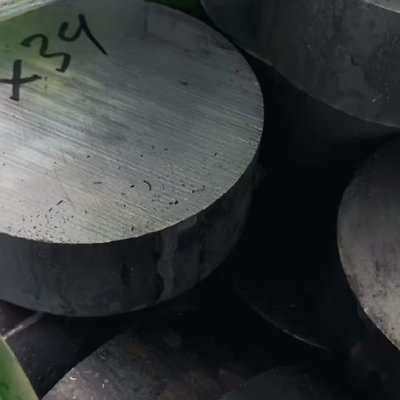

Χημική Χώρος Εφαρμογή Νικέλιο κράμα C276 Στρογγυλή μπάρα / φωτεινή διάμετρος άξονα 6 - 300mm Custom Cuttiing σε μήκος

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | c276 |

| Ποσότητα παραγγελίας min | 500 κιλά |

| Τιμή | 40-45 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Λεπτομέρειες

| Προϊόντα | Πλάκα από κράμα νικελίου | Βαθμός | c276 |

|---|---|---|---|

| Διάμετρος | 6 - 350mm | Μήκος | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Πρότυπο | Astm en | Υπηρεσία | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | Μαύρο, φωτεινό. |

| Επισημαίνω | Nickel Alloy C276 round bar,Bright shaft C276 alloy,Custom cut C276 nickel bar |

||

Περιγραφή προϊόντων

Εφαρμογή Χημικής Περιοχής Ράβδος Στρογγυλή Κράματος Νικελίου C276 / Φωτεινός Άξονας Διάμετρος 6 - 300mm Προσαρμοσμένη Κοπή σε Μήκος

Γρήγορες Πληροφορίες

| Βαθμός | Hastelloy C276 / 2.4819 | Σχήμα | Στρογγυλή Ράβδος |

| Διάμετρος | 6.0 - 350mm | Τύπος | Θερμής έλασης, σφυρηλάτησης |

| Μήκος | Προσαρμοσμένη κοπή σε οποιοδήποτε μήκος κατόπιν αιτήματος | Πιστοποιητικό | EN 10204-3.1 |

Περισσότερες Πληροφορίες Προδιαγραφών

| Όνομα Προϊόντος | Στρογγυλή Ράβδος / Ράβδος Hastelloy C276 |

| Διάμετρος | 6.0 - 350mm |

| Μήκος | προσαρμοσμένη κοπή σε οποιοδήποτε μήκος κατόπιν αιτήματος |

| Επιφάνεια | Μαύρο, φωτεινό |

| Μάρκα | DELTA |

| Υπηρεσία | κοπή |

| MOQ | 2 Kgs |

| Άλλος Τύπος | στρογγυλή ράβδος, ταινία, πηνίο, σωλήνας, φύλλο, πλάκα, σύρμα. κ.λπ. |

| Συσκευασία | αδιάβροχο χαρτί και ξύλινες παλέτες, ξύλινο κουτί |

| Λιμάνι Φόρτωσης | Λιμάνι Σαγκάης |

| Όρος Τιμής | EXW, FOB, CIF, CFR |

| Χρόνος Παράδοσης | εντός 12 ημερών |

Εφαρμογή Χημικής Περιοχής Ράβδος Στρογγυλή Κράματος Νικελίου C276 / Φωτεινός Άξονας Διάμετρος 6 - 300mm Προσαρμοσμένη Κοπή σε Μήκος

Η στρογγυλή ράβδος κράματος νικελίου C276 (γνωστή και ως φωτεινός άξονας όταν φινίρεται σε επιφάνεια υψηλής γυαλάδας) είναι ένα κορυφαίο δομικό υλικό ανθεκτικό στη διάβρωση, σχεδιασμένο για ακραία χημικά περιβάλλοντα. Με εύρος διαμέτρου 6–300mm και προσαρμόσιμη κοπή μήκους, προσφέρει εξαιρετική απόδοση σε σενάρια όπου τα περισσότερα μέταλλα αποτυγχάνουν, καθιστώντας το ένα ακρογωνιαίο υλικό στη χημική επεξεργασία, τα πετροχημικά και άλλους επιθετικούς βιομηχανικούς τομείς. Ακολουθεί μια λεπτομερής ανάλυση των παραμέτρων, των ιδιοτήτων, των διαδικασιών κατασκευής, των προτύπων, των ισοδύναμων βαθμών και των εφαρμογών του.

1. Βασικές Προδιαγραφές (Παράμετροι)

Οι διαστάσεις και η χημική σύνθεση της στρογγυλής ράβδου C276 ελέγχονται αυστηρά για να διασφαλιστεί η συνέπεια και η αξιοπιστία, ειδικά για κρίσιμες χημικές εφαρμογές.

| Κατηγορία | Λεπτομέρειες |

|---|---|

| Διαστάσεις | - Διάμετρος: 6mm – 300mm (καλύπτει μικρά εξαρτήματα ακριβείας έως μεγάλα δομικά στοιχεία) - Μήκος: Διατίθεται προσαρμοσμένη κοπή (κοινά εύρη: 100mm – 6000mm; προσαρμοσμένο σε σχέδια πελατών ή ανάγκες συναρμολόγησης) - Φινίρισμα επιφάνειας: Φωτεινός άξονας (Ra ≤ 0,8μm, επιτυγχάνεται μέσω λείανσης/στίλβωσης ακριβείας) ή μαύρο φινίρισμα οξειδίου (για προστασία από τη σκουριά κατά την αποθήκευση) |

| Χημική Σύνθεση (%) | - Νικέλιο (Ni): 57 min (βασικό στοιχείο, εξασφαλίζει αντοχή στη διάβρωση και ολκιμότητα) - Χρώμιο (Cr): 14,5 – 16,5 (ενισχύει την αντοχή στην οξείδωση και την διάβρωση) - Μολυβδαίνιο (Mo): 15,0 – 17,0 (κλειδί για την αντοχή στην ρωγμάτωση λόγω διάβρωσης από χλωρίδια) - Βολφράμιο (W): 3,0 – 4,5 (ενισχύει την αντοχή στη διάβρωση) - Σίδηρος (Fe): 4,0 – 7,0 (βελτιώνει την μηχανική κατεργασία χωρίς συμβιβασμούς στην απόδοση κατά της διάβρωσης) - Άνθρακας (C): 0,01 max (ελαχιστοποιεί την κατακρήμνιση καρβιδίου, αποτρέποντας τη διακοκκώδη διάβρωση) - Πυρίτιο (Si): 0,08 max, Μαγγάνιο (Mn): 1,0 max (ιχνοστοιχεία για επεξεργασιμότητα) |

| Μηχανικές Ιδιότητες (Ανοπτημένη Κατάσταση) | - Αντοχή σε εφελκυσμό: ≥ 690 MPa - Όριο διαρροής (0,2% Offset): ≥ 275 MPa - Επιμήκυνση (σε 50mm): ≥ 40% - Σκληρότητα: ≤ 210 HB (Brinell) ή ≤ 220 HV (Vickers) |

2. Βασικά Χαρακτηριστικά Απόδοσης

Η απόδοση της στρογγυλής ράβδου C276 καθορίζεται από την απαράμιλλη αντοχή στη διάβρωση και τις ισορροπημένες μηχανικές ιδιότητες, καθιστώντας την κατάλληλη για σκληρά χημικά περιβάλλοντα:

2.1 Εξαιρετική Αντοχή στη Διάβρωση

- Ευρεία Χημική Ανοχή: Αντιστέκεται στα περισσότερα οργανικά οξέα (π.χ., οξικό οξύ, μυρμηκικό οξύ), ανόργανα οξέα (π.χ., θειικό οξύ, υδροχλωρικό οξύ έως 50% συγκέντρωση), αλκάλια και διαλύματα αλάτων (π.χ., θαλασσινό νερό, άλμη). Είναι ένα από τα λίγα κράματα που αντέχουν σε υγρό αέριο χλωρίου και μέσα πλούσια σε χλωρίδια (μια σημαντική αιτία ρωγμάτωσης λόγω διάβρωσης σε ανοξείδωτους χάλυβες).

- Χωρίς Διακοκκώδη Διάβρωση: Η χαμηλή περιεκτικότητα σε άνθρακα (≤0,01%) και ο ελεγχόμενος κράμα αποτρέπουν την κατακρήμνιση καρβιδίου κατά τη συγκόλληση ή τη θερμική επεξεργασία—εξαλείφοντας τους κινδύνους διακοκκώδους διάβρωσης σε χημικούς αντιδραστήρες.

2.2 Μηχανική & Θερμική Σταθερότητα

- Ολκιμότητα & Ανθεκτικότητα: Διατηρεί υψηλή επιμήκυνση (≥40%) ακόμη και σε κρυογονικές θερμοκρασίες (-270°C), καθιστώντας την κατάλληλη για χημική αποθήκευση χαμηλής θερμοκρασίας. Σε αυξημένες θερμοκρασίες (έως 1093°C), διατηρεί επαρκή αντοχή για εξοπλισμό επεξεργασίας υψηλής θερμοκρασίας.

- Συγκολλησιμότητα: Συμβατό με κοινές μεθόδους συγκόλλησης (TIG, MIG, SMAW) χωρίς προθέρμανση ή θερμική επεξεργασία μετά τη συγκόλληση (PWHT), μειώνοντας την πολυπλοκότητα της παραγωγής για μεγάλα χημικά δοχεία.

2.3 Απόδοση επιφάνειας (Πλεονέκτημα φωτεινού άξονα)

Το φινίρισμα φωτεινού άξονα (Ra ≤ 0,8μm) προσφέρει δύο κρίσιμα οφέλη για χημικές εφαρμογές:

- Ελαχιστοποιεί το σχηματισμό ρωγμών (όπου συχνά ξεκινά η διάβρωση) στην επιφάνεια της ράβδου.

- Εξασφαλίζει ομαλή ροή υλικού σε εξαρτήματα χειρισμού υγρών (π.χ., βαλβίδες, αντλίες), μειώνοντας την τριβή και τη συσσώρευση χημικών.

3. Διαδικασία Κατασκευής

Η παραγωγή στρογγυλής ράβδου C276 ακολουθεί αυστηρούς ποιοτικούς ελέγχους για την τήρηση των προτύπων της χημικής βιομηχανίας, με βασικά βήματα που περιλαμβάνουν:

-

Τήξη & Χύτευση κράματος:

- Οι πρώτες ύλες (υψηλής καθαρότητας Ni, Cr, Mo, W) τήκονται σε ηλεκτρικό φούρνο τόξου (EAF) ή τήξη επαγωγής κενού (VIM) για την αποφυγή μόλυνσης από ακαθαρσίες.

- Το τηγμένο κράμα χυτεύεται σε κυλινδρικά πλινθώματα (μέγεθος που ταιριάζει με την τελική διάμετρο της ράβδου) για να εξασφαλιστεί ομοιόμορφη δομή κόκκων.

-

Θερμή σφυρηλάτηση & έλαση:

- Τα πλινθώματα θερμαίνονται στους 1150–1200°C και σφυρηλατούνται σε χοντρά στρογγυλά τεμάχια, διασπώντας τους χοντρούς κόκκους και βελτιώνοντας τις μηχανικές ιδιότητες.

- Τα τεμάχια στη συνέχεια θερμαίνονται στην επιθυμητή διάμετρο (6–300mm) μέσω μύλων έλασης πολλαπλών διαδρομών, εξασφαλίζοντας ακρίβεια διαστάσεων.

-

Θερμική επεξεργασία:

- Ανόπτηση: Πραγματοποιείται στους 1120–1150°C για 30–60 λεπτά, ακολουθούμενη από ταχεία απόσβεση νερού. Αυτό το βήμα μαλακώνει το υλικό (μειώνοντας τη σκληρότητα σε ≤210 HB) και εξαλείφει τις εσωτερικές τάσεις—κρίσιμο για την επακόλουθη μηχανική κατεργασία.

-

Μηχανική κατεργασία ακριβείας & φινίρισμα επιφάνειας:

- Για φωτεινούς άξονες: Ψυχρή έλξη (για βελτίωση της ανοχής διαμέτρου) ακολουθούμενη από λείανση και στίλβωση χωρίς κέντρο για την επίτευξη τραχύτητας επιφάνειας Ra ≤ 0,8μm.

- Προσαρμοσμένη κοπή: Χρησιμοποιούνται πριόνια CNC ή μηχανές κοπής με λέιζερ για την κοπή των ράβδων σε μήκη που καθορίζονται από τον πελάτη (ανοχή: ±0,5mm για μήκη ≤1000mm), εξασφαλίζοντας συμβατότητα με τις απαιτήσεις συναρμολόγησης.

-

Έλεγχος ποιότητας:

- Δοκιμή χημικής σύνθεσης (μέσω 光谱分析 / φασματοσκοπία εκπομπής οπτικού φωτός, OES).

- Δοκιμή μηχανικών ιδιοτήτων (δοκιμές εφελκυσμού, σκληρότητας, κρούσης).

- Έλεγχος διαστάσεων (χρησιμοποιώντας διαμετρητές, μικρόμετρα ή σαρωτές λέιζερ).

- Επαλήθευση αντοχής στη διάβρωση (δοκιμές ψεκασμού αλατιού ή δοκιμές εμβάπτισης σε προσομοιωμένα χημικά περιβάλλοντα).

4. Βιομηχανικά Πρότυπα

Η στρογγυλή ράβδος C276 συμμορφώνεται με τα παγκόσμια πρότυπα για να διασφαλιστεί η εναλλαξιμότητα και η απόδοση σε διεθνή χημικά έργα:

| Οργανισμός Προτύπων | Σχετικά Πρότυπα |

|---|---|

| ASTM International (USA) | - ASTM B574: Τυπική προδιαγραφή για κράματα νικελίου-χρωμίου-μολυβδαινίου-κολουμβίου (UNS N10276) Ράβδος, Ράβδος και Σύρμα - ASTM B622: Τυπική προδιαγραφή για κράματα νικελίου-χρωμίου-μολυβδαινίου (UNS N10276) Πλάκα, Φύλλο και Ταινία (αναφέρεται για τη συνέπεια του κράματος) |

| ASME (USA) | - ASME SB574: Boiler and Pressure Vessel Code (BPVC) 认可 standard for C276 bar (critical for pressure-containing components in chemical reactors) |

| DIN (Γερμανία) | - DIN 17750: Nickel and Nickel Alloy Semi-Finished Products (covers C276 bar dimensions and properties) |

| JIS (Ιαπωνία) | - JIS H4553: Nickel Alloys for Pressure Vessels and Piping (includes C276 equivalent grades) |

| ISO (Διεθνές) | - ISO 9723: Nickel and Nickel Alloys – Rods and Bars (general specification for C276 bar) |

5. 相近牌号 (Ισοδύναμοι Βαθμοί)

Το C276 είναι καταχωρημένο στο UNS (Unified Numbering System) ως N10276. Τα διεθνή του ισοδύναμα είναι:

| Χώρα/Περιοχή | Πρότυπο | Βαθμός/Ονομασία |

|---|---|---|

| ΗΠΑ | ASTM/ASME | N10276 (C276) |

| Γερμανία | DIN | 2.4819 |

| Ιαπωνία | JIS | NW276 |

| Γαλλία | AFNOR | NC17D |

| Κίνα | GB/T | NS3306 |

| Διεθνές | ISO | NiCr16Mo16W4 |

6. Εφαρμογή σε Χημικές & Συναφείς Βιομηχανίες

Η αντοχή στη διάβρωση και οι προσαρμόσιμες διαστάσεις της στρογγυλής ράβδου C276 την καθιστούν ιδανική για κρίσιμα εξαρτήματα στη χημική επεξεργασία και σε επιθετικά περιβάλλοντα:

6.1 Βασικές Εφαρμογές Χημικής Βιομηχανίας

- Χημικοί Αντιδραστήρες & Δοχεία: Χρησιμοποιούνται για εσωτερικούς άξονες, ράβδους αναδευτήρα και δομές στήριξης σε αντιδραστήρες που χειρίζονται θειικό οξύ, υδροχλωρικό οξύ ή χλωριωμένους διαλύτες.

- Εξαρτήματα χειρισμού υγρών: Κατεργασμένα σε βαλβίδες, άξονες αντλιών και εξαρτήματα για συστήματα μεταφοράς χημικών (αντιστέκεται στη διάβρωση από υγρά υψηλής ταχύτητας).

- Εναλλάκτες θερμότητας: Χρησιμοποιούνται ως φύλλα σωλήνων ή ράβδοι διαφράγματος σε εναλλάκτες θερμότητας για ανάκτηση οξέων (αντέχουν σε κύκλους θερμοκρασίας και όξινα ψυκτικά).

6.2 Εκτεταμένες Βιομηχανικές Χρήσεις

- Πετροχημικά: Εξαρτήματα για υπεράκτιες πλατφόρμες πετρελαίου (αντοχή στο θαλασσινό νερό) και διυλιστήρια (χειρίζεται παράγωγα αργού πετρελαίου και θειούχο υδρογόνο).

- Φαρμακευτικά: Υγιείς φωτεινοί άξονες για εξοπλισμό ανάμειξης (η λεία επιφάνεια αποτρέπει τη συσσώρευση βακτηρίων και συμμορφώνεται με τα πρότυπα FDA).

- Επεξεργασία λυμάτων: Ράβδοι για άξονες αεριστήρων και αντλίες ιλύος σε βιομηχανικές μονάδες επεξεργασίας λυμάτων (αντιστέκεται σε διαβρωτικά απόβλητα όπως άλατα βαρέων μετάλλων).

![]()

![]()

![]()

![]()

Συνιστώμενα προϊόντα