-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

AISI 434 Stainless Steel Strips 0.5mm 0.6mm 0.8mm ASME SA240

| Products | Stainless Steel Strip | Thickness | 0.4 - 3.0mm |

|---|---|---|---|

| Width | Within 1219mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | AISI 434 stainless steel strips,0.5mm stainless steel strip,ASME SA240 steel strips |

||

AISI434 Stainless Steel Strips Alloy 434 SS Strips Thickness 0.5mm 0.6mm 0.8mm ASME SA240

Product Attributes

| Attribute | Value |

| Products | SUS316L stainless steel strip |

| Thickness | 0.3-3.0mm |

| Width | within 1219mm |

| MOQ | 500 kgs |

| Other | 201 301 304 304L 309S 310S 316L 316Ti 410 420 430 436 439 441 444 440A/B/C,2205,2507,904L,C276,400,600,625,926,825.etc |

| Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS |

| Packing | wooden frame and water proof paper |

AISI 434 stainless steel strips are ferritic chromium-molybdenum alloys offering enhanced corrosion resistance—particularly against chlorides—at a lower cost than nickel-based grades. Compliant with ASME SA240 for pressure vessel and general applications, these cold-rolled strips are supplied in precise thicknesses (0.5mm, 0.6mm, 0.8mm) for demanding industrial sectors.

1. Standard Compliance & Key Specifications

-

Primary Standard: ASME SA240 governs chemical composition, mechanical properties, and tolerances for sheets/strips.

-

Thickness Range: 0.5mm, 0.6mm, 0.8mm (cold-rolled), with widths up to 2,000 mm and custom coil lengths.

-

Tolerances: Strict adherence to ASME SA240 dimensional tolerances (±0.02 mm for thin gauges).

2. Chemical Composition & Core Properties

Chemical Requirements (Weight %)

| Element | Min (%) | Max (%) |

|---|---|---|

| C | - | 0.12 |

| Cr | 16.0 | 18.0 |

| Mo | 0.75 | 1.25 |

| Mn | - | 1.00 |

| Si | - | 1.00 |

| S | - | 0.03 |

| P | - | 0.04 |

Key Enhancements:

-

Molybdenum Addition: Improves pitting/crevice corrosion resistance in chloride environments (e.g., automotive exteriors, coastal structures).

-

Low Carbon: Minimizes sensitization during welding, though post-weld annealing is recommended for critical applications.

-

Ferritic Structure: Inherent magnetic properties and resistance to stress corrosion cracking.

Mechanical Properties (Annealed State)

| Property | Value |

|---|---|

| Tensile Strength | ≥450 MPa |

| Yield Strength | ≥205 MPa |

| Elongation | ≥22% |

| Hardness (max) | 183 HB |

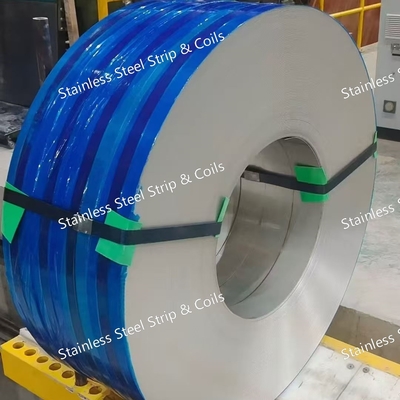

3. Surface Finishes and Forms

-

Standard Finish: 2B (smooth, lightly reflective), BA (bright annealed), No.4 (brushed), HL (hairline).

-

Forms: Precision slitted strips, coils (ID: 200–508 mm), or cut-to-length sheets.

4. Global Equivalent Grades

AISI 434 is standardized across major industrial regions:

| Region | Standard | Grade |

|---|---|---|

| USA | UNS/ASTM | S43400 |

| Japan | JIS | SUS 434 |

| Europe | DIN | 1.4113 |

| China | GB | 1Cr17Mo |

| UK | BS | 434 S 19 |

5. Heat Treatment & Fabrication Notes

-

Annealing: 788–872°C (1450–1600°F), air-cooled to relieve stresses and restore corrosion resistance.

-

Forging: Preheat to 1094–1149°C (2000–2100°F) to avoid cracking.

-

Limitations:

-

Cannot be hardened by heat treatment (ferritic structure).

-

Moderate formability; avoid deep drawing without intermediate annealing.

-

6. Industrial Applications

-

Automotive: Trim, wheel covers, exhaust components (superior salt resistance vs. 430 grades).

-

Consumer Durables: Kitchen appliances, sinks, washing machine drums.

-

Industrial Hardware:

-

Chemical tanks (non-oxidizing acid environments).

-

Conveyor chains (e.g., LH0834SS/BL434SS chains for food processing).

-

Electromagnetic components (valves, pump parts due to magnetic properties)

-

7. Manufacturer & Quality Assurance

-

Key Suppliers: TISCO (China), BAOSTEEL (China), POSCO (Korea)

-

Testing: Chemical analysis (OES/XRF), tensile tests (ASTM E8), hardness validation.

8. Advantages vs. Limitations

| Advantages | Limitations |

|---|---|

| Cost-effective (Ni-free) | Lower toughness at cryogenic temps |

| Resists chloride SCC* | Poor cold forging performance |

| Magnetic for EM applications | Limited weld ductility |

![]()

![]()

![]()

![]()