Tutti i prodotti

-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

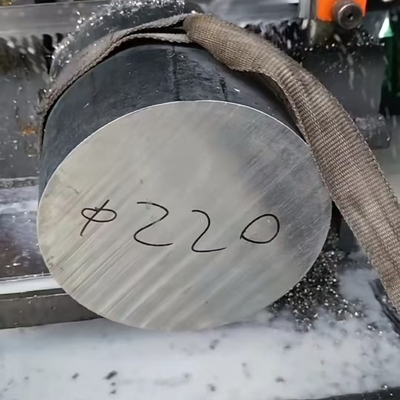

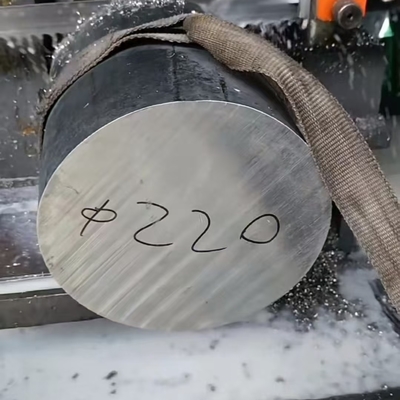

Barra rotonda di lega di nichel laminata a caldo UNS N10276 / 2.4819 / Lega C276 Rod rotondo ASTM EN GB Standard

| Luogo di origine | Cina |

|---|---|

| Marca | DELTA |

| Certificazione | ISO |

| Numero di modello | c276 |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 40-45 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 3 tonnellate a settimana |

Dettagli

| Prodotti | Placca in lega di nichel | Grado | c276 |

|---|---|---|---|

| Diametro | 6 - 350 mm | Lunghezza | taglio su misura di qualsiasi lunghezza su richiesta |

| Standard | Astm en | Servizio | Taglio |

| Porta di caricamento | Shanghai Port | Superficie | nero, luminoso |

| Evidenziare | Hot Rolled Nickel Alloy Round Bar,UNS N10276 Round Rod,Alloy C276 ASTM Standard |

||

Descrizione di prodotto

Barra rotonda di lega di nichel laminata a caldo UNS N10276 / 2.4819 / Lega C276 Rod rotondo ASTM EN GB Standard

Informazioni veloci

| Grado | Hastelloy C276 / 2.4819 | Forma | Barra rotonda |

| Diametro | 6.0 - 350 mm | Tipo | Scaldacciato, forgiato |

| Distanze | Taglio personalizzato di qualsiasi lunghezza su richiesta | Certificato | EN 10204-3.1 |

Maggiori informazioni sulle specifiche

| Nome dei prodotti | Hastelloy C276 barra rotonda / canna |

| Diametro | 6.0 - 350 mm |

| Distanze | taglio su misura di qualsiasi lunghezza su richiesta |

| Superficie | Nero, luminoso. |

| Marchio | DELTA |

| Servizio | taglio |

| MOQ | 2 kg |

| Altri tipi | Barra rotonda, striscia, bobina, tubo, foglio, piastra, filo, ecc. |

| Imballaggio | carta impermeabile e pallet di legno, scatola di legno |

| Porto di carico | Porto di Shanghai |

| Termine del prezzo | EXW, FOB, CIF, CFR |

| Tempo di consegna | entro 12 giorni |

Lega C276 Rod rotondo ASTM EN GB Standard

La lega C276 (UNS N10276, Werkstoff Nr. 2.4819) è una lega di nichel-molibdeno-cromo-tungsteno nota per la sua eccezionale resistenza alla corrosione negli ambienti industriali più difficili,in particolare contro gli agenti ossidanti e riducentiLe barre rotonde di lega C276 laminate a caldo sono ampiamente utilizzate in applicazioni critiche in cui la durata, la stabilità chimica e la resistenza meccanica non sono negoziabili.Di seguito è riportata una panoramica completa dei suoi parametri, proprietà, processo di produzione, norme, gradi equivalenti e applicazioni.

1Composizione chimica (parametri chiave)

Le prestazioni superiori della lega C276 derivano dalla sua composizione chimica controllata con precisione, che bilancia resistenza alla corrosione e proprietà meccaniche.La composizione tipica (per ASTM B574) è la seguente::

| Elemento | Intervallo di contenuto (%) | Funzione primaria |

|---|---|---|

| Nilo (Ni) | ≥ 57 | Metallo non metallico; fornisce stabilità strutturale e resistenza al cloruro (SCC) |

| Cromo (Cr) | 14.5 - 16.5 | Migliora la resistenza agli agenti ossidanti (ad esempio acido nitrico, aria e acqua di mare) |

| Molibdeno (Mo) | 15.0 - 17.0 | Migliora la resistenza ai mezzi riducenti (ad esempio, acido solforico, acido cloridrico) |

| Volframmo (W) | 3.0 - 4.5 | Migliora la resistenza alla corrosione delle fessure e delle crepe; rafforza la lega |

| Ferro (Fe) | ≤ 50 | Riduce il costo delle leghe mantenendo la duttilità |

| Carbonio (C) | ≤ 0.01 | Minimizza la precipitazione di carburo (evitando la corrosione intergranulare in servizio ad alta temperatura) |

| Silicio (Si) | ≤ 0.08 | Controlla l'ossidazione durante la fusione; limita la fragilità indotta dalle impurità |

| Manganese (Mn) | ≤ 10 | Migliora la lavorabilità a caldo durante la laminazione |

| Fosforo (P) | ≤ 0.04 | Riduce i rischi di fragilità |

| Sulfuro (S) | ≤ 0.03 | Minimizza le crepe durante la fabbricazione |

2Proprietà meccaniche e fisiche

Le barre rotonde laminate a caldo in lega C276 presentano una combinazione unica di elevata resistenza, duttilità e stabilità termica, che le rende adatte sia per applicazioni ambientali che a temperature elevate.

2.1 Proprietà meccaniche (in stato di laminatura a caldo, secondo ASTM B574)

| Immobili | Standard di prova | Valore (tipico) | Unità |

|---|---|---|---|

| Resistenza alla trazione (UTS) | ASTM E8 | ≥ 795 | MPa |

| Forza del rendimento (0,2% Offset) | ASTM E8 | ≥ 310 | MPa |

| Allungamento (in 50 mm) | ASTM E8 | ≥ 40 | % |

| Durezza (Brinell) | ASTM E10 | ≤ 210 | HB |

Nota: il trattamento post-calore (ad esempio, ricottura della soluzione a 1120 ∼ 1150 °C seguita da un'accesa rapida) può ottimizzare ulteriormente la robustezza e la resistenza alla corrosione eliminando le sollecitazioni residue.

2.2 Proprietà fisiche

| Immobili | Valore | Unità |

|---|---|---|

| Densità | 8.89 | g/cm3 |

| Distanza di fusione | 1325 ¢ 1370 | °C |

| Conduttività termica (25°C) | 10.8 | W/(m·K) |

| Coefficiente di espansione termica (20-100°C) | 12.4 × 10−6 | /°C |

| Resistenza elettrica (25°C) | 1.37 × 10−6 | Omm |

3. Processo di produzione di barre rotonde di lega C276 laminate a caldo

Il processo di fabbricazione delle barre rotonde laminate a caldo in lega C276 aderisce a severi controlli di qualità per garantire la coerenza e le prestazioni.

-

Fusione e fusione di materie prime

- Il nichel, il molibdeno, il cromo e il tungsteno di alta purezza vengono fusi in un forno ad arco elettrico (EAF) o in un forno a fusione per induzione a vuoto (VIM) per evitare la contaminazione.

- La lega fusa viene versata in lingotti cilindrici (billet) mediante fusione continua o statica, con diametri compresi tra 150 mm e 500 mm.

-

Omogenizzazione Annegamento

- I biglietti vengono riscaldati a 1050 ‰ 1100 °C e tenuti per 8 ‰ 12 ore per eliminare la segregazione chimica e migliorare la lavorabilità.

-

Rivestimento a caldo

- I biglietti ricottati vengono riscaldati a 1000-1100 °C (la gamma ottimale di temperatura di lavorazione a caldo della lega) e passati attraverso una serie di laminatori.

- Le lastre vengono gradualmente ridotte in diametro per formare barre rotonde della dimensione desiderata (diametri comuni: 10 mm ≈ 300 mm).

-

Soluzione Annellazione e estinzione

- Dopo la laminazione, le barre sono sottoposte a ricottura in soluzione a 1120 ∼ 1150 °C per 30 ∼ 60 minuti, quindi rapidamente spegnite in acqua o aria.ripristinare la massima resistenza alla corrosione.

-

Trattamento superficiale

- Le barre vengono descalinate (per decapaggio con acido nitrico-idrofluorico) per rimuovere gli strati di ossido formati durante la laminazione.

- Processi di finitura facoltativi: macinazione, lucidatura o tornitura per ottenere tolleranze dimensionali precise (ad esempio, h9/h10) e rugosità superficiale (Ra ≤ 6,3 μm).

-

Ispezione della qualità

- Prova non distruttiva (NDT): prova ad ultrasuoni (UT) per i difetti interni, prova a particolato magnetico (MT) per le crepe superficiali.

- Analisi della composizione chimica (attraverso l'analisi del espectro, OES), test delle proprietà meccaniche (trassili, durezza) e verifica dimensionale.

4. Norme internazionali

Le barre rotonde in lega C276 sono prodotte e ispezionate in conformità con gli standard globali per garantire l'interoperabilità tra le industrie.

| Sistema standard | Numero standard | Portata della specifica |

|---|---|---|

| ASTM (USA) | ASTM B574 | Specifica standard per le barre e le barre in lega di nichel-cromo-molibdeno-tungsteno (UNS N10276) |

| EN (Europa) | EN 10088-3 | Acciai inossidabili e acciai resistenti al calore ¢ Parte 3: Prodotti fabbricati (lega 2.4819) |

| GB (Cina) | GB/T 2054 | Barre e barre di nichel e di leghe di nichel (classe equivalente: N06276) |

| ISO | ISO 6208 | Barre e barre di nichel e lega di nichel (requisiti generali per la lega C276) |

5. Gradi equivalenti

La lega C276 è standardizzata sotto diverse denominazioni in tutto il mondo.

| Sistema standard | Indicazione del grado | Corrispondente lega |

|---|---|---|

| UNS (USA) | N10276 dell'UNS | Leghe C276 |

| DIN/EN (Europa) | Materiale di produzione 2.4819 | Leghe C276 |

| GB (Cina) | N06276 | Leghe C276 |

| JIS (Giappone) | NW2276 | Leghe C276 |

| BS (Regno Unito) | NA 21 | Leghe C276 |

6Applicazioni

Le barre rotonde in lega C276 sono preferite nelle industrie che richiedono una resistenza alla corrosione superiore e un'affidabilità meccanica in condizioni estreme.

-

Industria di trasformazione chimica

- Componenti per la produzione di acido solforico (reattori, scambiatori di calore), manipolazione dell'acido cloridrico (pompe, valvole) e sintesi farmaceutica (reattori).

-

Industria del petrolio e del gas

- attrezzi per pozzi, componenti per teste di pozzo e parti di condotte per ambienti di gas acidi e offshore (resistente all'H2S e alla SCC indotta da cloruro).

-

Ingegneria ambientale

- Sistemi di desolforazione dei gas di combustione (FGD), attrezzature per il trattamento delle acque reflue e parti di inceneritori (resistono ai fumi acidi e alle alte temperature).

-

Aerospaziale e Difesa

- Componenti del motore, ugelli del razzo e hardware militare (tollerano l'ossidazione ad alta temperatura e l'esposizione chimica).

-

Altri settori ad alte prestazioni

- Componenti delle centrali nucleari (resistenti alla degradazione indotta dalle radiazioni), ingegneria navale (fasciatori resistenti all'acqua di mare) e attrezzature per la produzione di semiconduttori (requisiti di alta purezza).

![]()

![]()

![]()

![]()

Prodotti raccomandati