Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

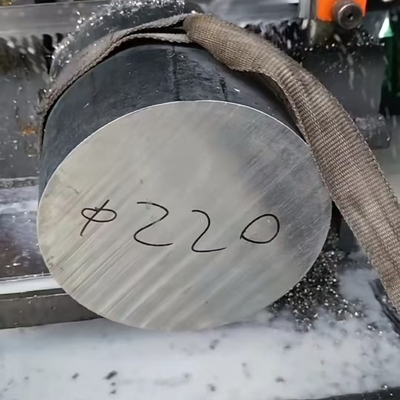

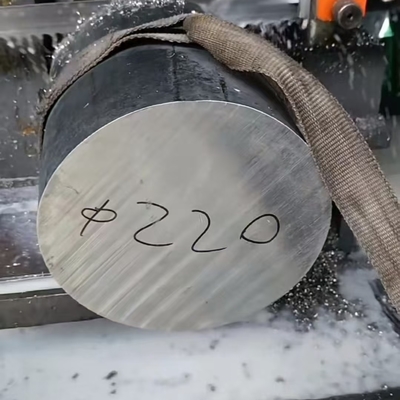

Στρογγυλή ράβδος θερμής έλασης νικελίου UNS N10276 / 2.4819 / Στρογγυλή ράβδος C276

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | c276 |

| Ποσότητα παραγγελίας min | 500 κιλά |

| Τιμή | 40-45 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Λεπτομέρειες

| Προϊόντα | Πλάκα από κράμα νικελίου | Βαθμός | c276 |

|---|---|---|---|

| Διάμετρος | 6 - 350mm | Μήκος | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Πρότυπο | Astm en | Υπηρεσία | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | Μαύρο, φωτεινό. |

| Επισημαίνω | Hot Rolled Nickel Alloy Round Bar,UNS N10276 Round Rod,Alloy C276 ASTM Standard |

||

Περιγραφή προϊόντων

Στρογγυλή ράβδος θερμής έλασης νικελίου UNS N10276 / 2.4819 / Στρογγυλή ράβδος C276

Γρήγορες πληροφορίες

| Αξία | Χέιστελοϊ C276 / 2.4819 | Σχήμα | Στρογγυλή μπάρα |

| Διάμετρος | 6.0 - 350 mm | Τύπος | Ζεστά τυλιγμένα, σφυρηλατημένα |

| Διάρκεια | Προσαρμοσμένο Κόψιμο οποιουδήποτε μήκους κατά παραγγελία | Πιστοποιητικό | EN 10204-3.1 |

Περισσότερες πληροφορίες προδιαγραφών

| Ονομασία των προϊόντων | Χαστέλλοι C276 στρογγυλή ράβδο |

| Διάμετρος | 6.0 - 350 mm |

| Διάρκεια | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Επιφάνεια | Μαύρο, φωτεινό. |

| Ετικέτα | ΔΕΛΤΑ |

| Υπηρεσία | κοπή |

| Τροποποιημένο | 2 κιλά |

| Άλλος τύπος | Στρογγυλή ράβδο, ταινία, τροχιά, σωλήνα, φύλλο, πλάκα, σύρμα κλπ. |

| Συσκευή | υδατοασφαλές χαρτί και ξύλινες παλέτες, ξύλινο κουτί |

| Λιμένας φόρτωσης | Λιμάνι της Σαγκάης |

| Όρος τιμής | Επικαιροποιημένα προϊόντα |

| Χρόνος παράδοσης | εντός 12 ημερών |

Σύνθετο C276 στρογγυλή ράβδος ASTM EN GB Standard

Το κράμα C276 (UNS N10276, Werkstoff Nr. 2.4819) είναι κράμα νικελίου-μολυβδενίου-χρωμίου-τουλφστάνου, γνωστό για την εξαιρετική αντοχή του στη διάβρωση στα σκληρότερα βιομηχανικά περιβάλλοντα,ειδικότερα ενάντια σε οξειδωτικά και μειωτικά μέσαΟι στρογγυλές ράβδοι από κράμα C276 θερμής έλασης χρησιμοποιούνται ευρέως σε κρίσιμες εφαρμογές όπου η αντοχή, η χημική σταθερότητα και η μηχανική αντοχή δεν είναι διαπραγματεύσιμες.Παρακάτω παρουσιάζεται μια ολοκληρωμένη επισκόπηση των παραμέτρων του, ιδιότητες, διαδικασία παραγωγής, πρότυπα, ισοδύναμες ποιότητες και εφαρμογές.

1Χημική σύνθεση (κλειδιώδεις παράμετροι)

Η ανώτερη απόδοση του κράματος C276 οφείλεται στην ακριβώς ελεγχόμενη χημική του σύνθεση, η οποία εξισορροπεί την αντοχή στη διάβρωση και τις μηχανικές ιδιότητες.Η τυπική σύνθεση (ανά ASTM B574) είναι η ακόλουθη::

| Στοιχείο | Περιοχή περιεχομένου (%) | Πρωταρχική λειτουργία |

|---|---|---|

| Νικέλιο (Ni) | ≥ 57 | Βασικό μέταλλο. Παρέχει δομική σταθερότητα και αντοχή στην διάσπαση διά διά διάβρωσης από χλωρίδιο (SCC) |

| Χρώμιο (Cr) | 14.5 - 16.5 | Βελτιώνει την αντοχή σε οξειδωτικά μέσα (π.χ. νιτρικό οξύ, αέρας και θαλάσσιου νερού) |

| Μολυβδένιο (Mo) | 15.0 - 17.0 | Βελτιώνει την αντοχή σε περιοριστικά μέσα (π.χ. θειικό οξύ, υδροχλωρικό οξύ) |

| Τούλφραμ (W) | 3.0 - 4.5 | Ενισχύει την αντοχή στη διάβρωση και τη διάσπαση, ενισχύει το κράμα |

| Σίδηρος (Fe) | ≤ 5.0 | Μειώνει το κόστος του κράματος διατηρώντας την ευελιξία |

| Άνθρακας (C) | ≤ 0.01 | Ελαχιστοποιεί τη βροχόπτωση καρβιδίων (αποφεύγει τη διασωματική διάβρωση σε υψηλές θερμοκρασίες) |

| Σιλικόνη (Si) | ≤ 0.08 | Ελέγχει την οξείδωση κατά τη διάρκεια της τήξης, περιορίζει την εύθραυστη κατάσταση που προκαλείται από τις προσμείξεις |

| Μαγγάνιο (Mn) | ≤ 1.0 | Βελτιώνει τη θερμή επεξεργασία κατά τη διάρκεια της έλασης |

| Φωσφόρος (P) | ≤ 0.04 | Μειώνει τους κινδύνους εύθραυσης |

| Θείο (S) | ≤ 0.03 | Ελαχιστοποιεί τις ρωγμές κατά την κατασκευή |

2Μηχανικές και φυσικές ιδιότητες

Οι στρογγυλές ράβδοι από κράμα C276 θερμής έλασης παρουσιάζουν έναν μοναδικό συνδυασμό υψηλής αντοχής, ευκαμψίας και θερμικής σταθερότητας, καθιστώντας τους κατάλληλους τόσο για εφαρμογές περιβάλλοντος όσο και για εφαρμογές υψηλής θερμοκρασίας.

2.1 Μηχανολογικές ιδιότητες (καυτή έλαση, σύμφωνα με την ASTM B574)

| Ιδιοκτησία | Πρότυπο δοκιμής | Αξία (τυπική) | Μονάδα |

|---|---|---|---|

| Δυνατότητα τράβηξης (UTS) | ΑΣTM E8 | ≥ 795 | MPa |

| Δυνατότητα απόδοσης (0,2% αντιστάθμιση) | ΑΣTM E8 | ≥ 310 | MPa |

| Επεκτάσεις (σε 50 mm) | ΑΣTM E8 | ≥ 40 | % |

| Σκληρότητα (Brinell) | ΑΣTM E10 | ≤ 210 | HB |

Σημείωση: Η μεταθερμική επεξεργασία (π.χ. αναψύκωση διαλύματος σε θερμοκρασία 1120°C· 1150°C, ακολουθούμενη από ταχεία ψύξη) μπορεί να βελτιστοποιήσει περαιτέρω την αντοχή και την αντοχή στη διάβρωση με την εξάλειψη των υπολειμματικών πιέσεων.

2.2 Φυσικές ιδιότητες

| Ιδιοκτησία | Αξία | Μονάδα |

|---|---|---|

| Σφιχτότητα | 8.89 | g/cm3 |

| Πεδίο τήξης | 1325 ̇ 1370 | °C |

| Θερμική αγωγιμότητα (25°C) | 10.8 | W/(m·K) |

| Συντελεστής θερμικής επέκτασης (20-100°C) | 12.4 × 10−6 | /°C |

| Ηλεκτρική αντίσταση (25°C) | 1.37 × 10−6 | Ω·μ |

3.Προϊόντα στρογγυλών ράβδων από κράμα C276 θερμής έλασης

Η διαδικασία κατασκευής των στρογγυλών ράβδων θερμής ένωσης C276 ακολουθεί αυστηρούς ελέγχους ποιότητας για να εξασφαλιστεί η συνέπεια και η απόδοση.

-

Έλιξη πρώτων υλών και χύτευση

- Το νικέλιο, το μολυβδένιο, το χρώμιο και το βολφράμιο υψηλής καθαρότητας λιώνουν σε ηλεκτρικό φούρνο τόξου (EAF) ή φούρνο τήξης με επαγωγή κενού (VIM) για να αποφευχθεί η μόλυνση.

- Το λιωμένο κράμα χύνεται σε κυλινδρικές ράβδους (σφραγίδες) με συνεχές ή στατικό χύτεμα, με διαμέτρους που κυμαίνονται από 150 mm έως 500 mm.

-

Ομογενοποίηση

- Τα μπουκάλια θερμαίνονται σε 1050-1100 °C και διατηρούνται για 8-12 ώρες για την εξάλειψη του χημικού διαχωρισμού και τη βελτίωση της εργασιακής ικανότητας.

-

Ζεστή έλαση

- Τα κατεψυγμένα τεμάχια θερμαίνονται σε 1000-1100 °C (το βέλτιστο εύρος θερμότητας εργασίας του κράματος) και περνούν μέσα από μια σειρά κυλίνδρων.

- Οι σφαιρίδες μειώνονται σταδιακά στη διάμετρο για να σχηματίσουν στρογγυλές ράβδους του επιθυμητού μεγέθους (κοινές διαμέτρους: 10 mm· 300 mm).

-

Λύση Αναψύκωση και σβήσιμο

- Μετά την έλαση, οι ράβδοι υποβάλλονται σε αναψύκωση διαλύματος σε θερμοκρασία 1120-1150 °C για 30-60 λεπτά, στη συνέχεια σβήνονται γρήγορα σε νερό ή αέρα.αποκατάσταση της μέγιστης αντοχής στη διάβρωση.

-

Επεξεργασία επιφάνειας

- Οι ράβδοι αφαιρούνται από την επιφάνεια (μέσω ακινητοποίησης με νιτρικό υδροφθορικό οξύ) για την αφαίρεση των στρωμάτων οξειδίων που σχηματίζονται κατά τη διάρκεια της έλασης.

- Προαιρετικές διαδικασίες τελικής επεξεργασίας: άλεση, γυαλισμός ή στροφή για την επίτευξη ακριβών διαμετρικών ανοχής (π.χ. h9/h10) και τραχύτητας επιφάνειας (Ra ≤ 6,3 μm).

-

Επιθεώρηση ποιότητας

- Μη καταστροφικές δοκιμές (NDT): δοκιμές υπερήχων (UT) για εσωτερικά ελαττώματα, δοκιμές μαγνητικών σωματιδίων (MT) για ρωγμές στην επιφάνεια.

- Ανάλυση χημικής σύνθεσης (μέσω ανάλυσης φωτεινής γραμμής, OES), δοκιμή μηχανικών ιδιοτήτων (ένταση, σκληρότητα) και επαλήθευση διαστάσεων.

4Διεθνή πρότυπα

Οι στρογγυλές ράβδοι από κράμα C276 κατασκευάζονται και επιθεωρούνται σύμφωνα με διεθνή πρότυπα για να εξασφαλιστεί η διαλειτουργικότητα σε διάφορες βιομηχανίες.

| Τυποποιημένο σύστημα | Τυπικός αριθμός | Πεδίο εφαρμογής των προδιαγραφών |

|---|---|---|

| ASTM (ΗΠΑ) | ΑΣTM B574 | Τυποποιημένη προδιαγραφή για ράβδους και ράβδους από κράμα νικελίου-χρώμου-μολυβδενίου-τουγκστίνης (UNS N10276) |

| EN (Ευρώπη) | Εναλλακτικά | Ατσάλι ατσάλι και ανθεκτικός στη θερμότητα ∆άμημα 3: Κατασκευασμένα προϊόντα (σύνθεση 2.4819) |

| GB (Κίνα) | GB/T 2054 | Άξονες και ράβδοι από νικέλιο και κράμα νικέλου (ισοδύναμη κλάση: N06276) |

| ISO | ISO 6208 | Ράβδοι και ράβδοι νικελίου και κράματος νικελίου (γενικές απαιτήσεις για το κράμα C276) |

5. Εξισοδύναμες βαθμίδες

Το κράμα C276 τυποποιείται σε διάφορες ονομασίες παγκοσμίως.

| Τυποποιημένο σύστημα | Ονομασία βαθμού | Αντίστοιχη κράμα |

|---|---|---|

| Εθνικές Υπηρεσίες (ΗΠΑ) | Εθνική Εθνική Σκηνοθεσία N10276 | Σύνθετο C276 |

| DIN/EN (Ευρώπη) | Werkstoff 2. Εργατικό υλικό4819 | Σύνθετο C276 |

| GB (Κίνα) | N06276 | Σύνθετο C276 |

| ΔΕΣ (Ιαπωνία) | ΝΔ 2276 | Σύνθετο C276 |

| BS (Ηνωμένο Βασίλειο) | NA 21 | Σύνθετο C276 |

6Εφαρμογές

Οι στρογγυλές ράβδοι από κράμα C276 ευνοούνται σε βιομηχανίες που απαιτούν ανώτερη αντοχή στη διάβρωση και μηχανική αξιοπιστία υπό ακραίες συνθήκες.

-

Χημική βιομηχανία

- Συστατικά για την παραγωγή θειικού οξέος (αντιδραστήρες, ανταλλακτές θερμότητας), μετακίνηση υδροχλωριούχου οξέος (πυροτριβές, βαλβίδες) και φαρμακευτική σύνθεση (κάσα αντίδρασης).

-

Βιομηχανία πετρελαίου και φυσικού αερίου

- Εργαλεία υποβρύχων, εξαρτήματα κεφαλών πηγάδιών και εξαρτήματα αγωγών για περιβάλλοντα υπεράκτιων και ξινών αερίων (αντιστέκονται στο H2S και στο SCC που προκαλείται από χλωρίδιο).

-

Μηχανική Περιβάλλοντος

- Συστήματα αποσβερίωσης καυσαερίων (FGD), εξοπλισμός επεξεργασίας λυμάτων και εξαρτήματα αποτεφρωτήρων (αντέχουν σε όξιους καπνούς και υψηλές θερμοκρασίες).

-

Αεροδιαστημική και Άμυνα

- Συστατικά του κινητήρα, πύραυλοι πυραύλων και στρατιωτικό υλικό (αντέχει την οξείδωση σε υψηλές θερμοκρασίες και την έκθεση σε χημικά).

-

Άλλοι κλάδοι υψηλής απόδοσης

- Συστατικά στοιχεία πυρηνικών σταθμών (αντιστέκονται στην υποβάθμιση που προκαλείται από ακτινοβολία), ναυτιλιακή μηχανική (απομονωμένα συσσωρευτικά) και εξοπλισμός κατασκευής ημιαγωγών (απαιτήσεις υψηλής καθαρότητας).

![]()

![]()

![]()

![]()

Συνιστώμενα προϊόντα