Alle producten

-

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

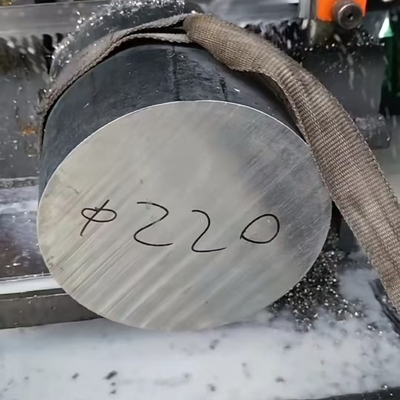

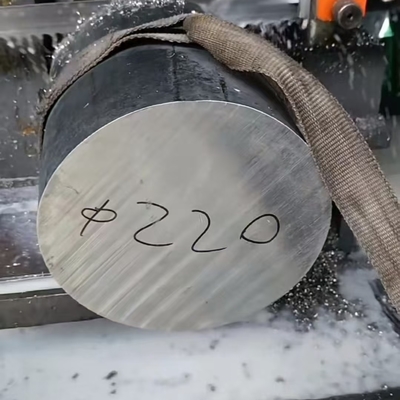

Warmgewalste ronde staaf van nikkel legering UNS N10276 / 2.4819 / Legering C276 Ronde staaf ASTM EN GB Standaard

Productdetails

| Producten | Platen van nikkellegering | Cijfer | c276 |

|---|---|---|---|

| Diameter | 6 - 350 mm | Lengte | op aanvraag op maat gesneden |

| Standaard | Astm en | Dienst | Snij |

| Laadpoort | Shanghai -haven | Oppervlak | Zwart, helder. |

| Markeren | Hot Rolled Nickel Alloy Round Bar,UNS N10276 Round Rod,Alloy C276 ASTM Standard |

||

Productomschrijving

Warmgewalste ronde staaf van nikkellegering UNS N10276 / 2.4819 / legering C276 Ronde staaf ASTM EN GB-standaard

Snelle informatie

| Graad | Hastelloy C276 / 2.4819 | Vorm | Ronde balk |

| Diameter | 6.0 - 350 mm | Type | Warmgewalst, gesmeed |

| Lange | Op maat gesneden | Certificaat | EN 10204-3.1 |

Meer informatie over de specificaties

| Naam van de producten | Hastelloy C276 Ronde staaf / staaf |

| Diameter | 6.0 - 350 mm |

| Lange | op aanvraag op maat gesneden |

| Oppervlakte | Zwart, helder. |

| Merken | DELTA |

| Diensten | snijden |

| MOQ | 2 kg |

| Andere soorten | Ronde staaf, strip, spoel, buis, plaat, plaat, draad, enz. |

| Verpakking | waterdicht papier en houten pallets, houten doos |

| Laadhaven | haven van Shanghai |

| Prijsduur | EXW, FOB, CIF, CFR |

| Leveringstermijn | binnen 12 dagen |

legering C276 Ronde staaf ASTM EN GB-norm

legering C276 (UNS N10276, Werkstoff Nr. 2.4819) is een legering van nikkel-molybdeen-chroom-wolfraam die bekend staat om zijn uitzonderlijke corrosiebestendigheid in de hardste industriële omgevingen,met name tegen oxiderende en reducerende mediaWarmgewalste ronde staven van legering C276 worden veel gebruikt in kritieke toepassingen waar duurzaamheid, chemische stabiliteit en mechanische sterkte niet onderhandelbaar zijn.Hieronder vindt u een uitgebreid overzicht van de parameters, eigenschappen, productieproces, normen, gelijkwaardige kwaliteiten en toepassingen.

1Chemische samenstelling (sleutelparameters)

De superieure prestaties van legering C276 zijn te danken aan de nauwkeurig gecontroleerde chemische samenstelling, die de corrosiebestendigheid en de mechanische eigenschappen in evenwicht brengt.De typische samenstelling (volgens ASTM B574) is als volgt::

| Elementen | Inhoudsgroep (%) | Hoofdfunctie |

|---|---|---|

| Nikkel (Ni) | ≥ 57 | Basismetaal; biedt structurele stabiliteit en weerstand tegen chloride-stresscorrosiecracking (SCC) |

| Chroom (Cr) | 14.5 tot 16.5 | Verbetert de weerstand tegen oxiderende stoffen (bijv. stikstofzuur, lucht en zeewater) |

| Molybdeen (Mo) | 15.0 tot 17.0 | Verbetert de weerstand tegen reducerende media (bijv. zwavelzuur, zoutzuur) |

| wolfraam (W) | 3.0 tot en met 4.5 | Verhoogt de weerstand tegen corrosie door pittingen en spleten; versterkt de legering |

| IJzer (Fe) | ≤ 50 | Vermindert de kosten van de legering en behoudt tegelijkertijd de ductiliteit |

| Koolstof (C) | ≤ 0.01 | Minimaliseert carbide neerslag (vermijdt intergranulaire corrosie bij hoge temperatuur) |

| Silicium (Si) | ≤ 0.08 | Beheert oxidatie tijdens het smelten; beperkt door onzuiverheden veroorzaakte breekbaarheid |

| Mangan (Mn) | ≤ 10 | Verbetert de warmbewerkbaarheid tijdens het walsen |

| Fosfor (P) | ≤ 0.04 | Vermindert het risico op broosheid |

| Zwavel (S) | ≤ 0.03 | Minimaliseert scheuren tijdens de fabricage |

2. Mechanische en fysische eigenschappen

Warmgewalste ronde staven van legering C276 vertonen een unieke combinatie van hoge sterkte, buigzaamheid en thermische stabiliteit, waardoor ze geschikt zijn voor zowel omgevings- als hogetemperatuurtoepassingen.

2.1 Mechanische eigenschappen (warmgewalst volgens ASTM B574)

| Vastgoed | Testnorm | Waarde (typisch) | Eenheid |

|---|---|---|---|

| Tensile sterkte (UTS) | ASTM E8 | ≥ 795 | MPa |

| Rentevermogen (0,2% Offset) | ASTM E8 | ≥ 310 | MPa |

| Verlenging (in 50 mm) | ASTM E8 | ≥ 40 | % |

| Hardheid (Brinell) | ASTM E10 | ≤ 210 | HB |

Opmerking: na warmtebehandeling (bijv. oplosmiddelverhitting bij 1120 ∼ 1150 °C gevolgd door snel afzuigen) kunnen de taaiheid en corrosiebestendigheid verder worden geoptimaliseerd door residuele spanningen te elimineren.

2.2 Fysieke eigenschappen

| Vastgoed | Waarde | Eenheid |

|---|---|---|

| Dichtheid | 8.89 | g/cm3 |

| Smeltebereik | 1325 ¢ 1370 | °C |

| Thermische geleidbaarheid (25°C) | 10.8 | W/(m·K) |

| Coëfficiënt van thermische uitbreiding (20 ̊100°C) | 12.4 × 10−6 | /°C |

| Elektrische weerstand (25°C) | 1.37 × 10−6 | Omm |

3. Productieproces van warmgewalste ronde staven van legering C276

Het productieproces van warmgewalste ronde staven van legering C276 voldoet aan strikte kwaliteitscontroles om de consistentie en prestaties te waarborgen.

-

Schmelten en gieten van grondstoffen

- Hoge zuiverheid nikkel, molybdeen, chroom en wolfraam worden gesmolten in een elektrische boogoven (EAF) of vacuüm inductie smeltoven (VIM) om verontreiniging te voorkomen.

- De gesmolten legering wordt gegoten in cilindrische balken (billets) door middel van continue gieten of statische gieten, met diameters variërend van 150 mm tot 500 mm.

-

Homogenisatie Reiniging

- Billets worden verwarmd tot 1050~1100°C en gedurende 8~12 uur gehouden om chemische segregatie te voorkomen en de werkbaarheid te verbeteren.

-

Warm gewalst

- Verhitte billets worden verwarmd tot 1000 ‰ 1100 °C (het optimale warmwerkingstemperatuurbereik van de legering) en worden door een reeks walsen geleid.

- De balken worden geleidelijk in diameter verkleind tot ronde balken van de gewenste grootte (gemeenschappelijke diameters: 10 mm·300 mm).

-

Oplossing Glijden en uitdooien

- Na het rollen worden de staven gedurende 30 tot 60 minuten bij 1120 tot 1150 °C met een oplossing gebrand en vervolgens snel in water of lucht gedoofd.herstel van maximale corrosiebestendigheid.

-

Oppervlaktebehandeling

- De staven worden ontkalkt (door bemonstering met stikstofuurzuur) om de oxidelagen te verwijderen die tijdens het rollen zijn ontstaan.

- Optioneel afwerkingsprocessen: slijpen, polijsten of draaien om een precieze afmetingstolerantie (bv. h9/h10) en oppervlaktrauwheid (Ra ≤ 6,3 μm) te bereiken.

-

Kwaliteitscontrole

- Niet-destructieve tests (NDT): Ultrasone testen (UT) op interne defecten, magnetische deeltjes testen (MT) op oppervlakte scheuren.

- Analyse van de chemische samenstelling (via lichtspektrologie, OES), testen van mechanische eigenschappen (tanningsvermogen, hardheid) en verificatie van de afmetingen.

4. Internationale normen

Ronde staven van legering C276 worden vervaardigd en geïnspecteerd in overeenstemming met wereldwijde normen om interoperabiliteit tussen industrieën te garanderen.

| Standaard systeem | Standaardnummer | Specificatie toepassingsgebied |

|---|---|---|

| ASTM (Verenigde Staten) | ASTM B574 | Standardspecificatie voor staven en staven van nikkel-chroom-molibdeen-tungstenlegering (UNS N10276) |

| EN (Europa) | EN 10088-3 | Roestvrij staal en warmtebestendige staal (deel 3: bewerkte producten) |

| GB (China) | GB/T 2054 | staven en staven van nikkel en van nikkellegeringen (gelijkwaardige waarde: N06276) |

| ISO | ISO 6208 | Staven en staven van nikkel en van nikkellegeringen (algemene voorschriften voor legering C276) |

5. Gelijkwaardige graden

De legering C276 is wereldwijd gestandaardiseerd onder verschillende benamingen.

| Standaard systeem | Groepsbenaming | overeenkomstige legering |

|---|---|---|

| UNS (VS) | N10276 van de VN | legering C276 |

| DIN/EN (Europa) | Werkstof 2.4819 | legering C276 |

| GB (China) | N06276 | legering C276 |

| JIS (Japan) | NW2276 | legering C276 |

| BS (Verenigd Koninkrijk) | NA 21 | legering C276 |

6. Toepassingen

Ronde staven van legering C276 worden de voorkeur gegeven in industrieën die een superieure corrosiebestendigheid en mechanische betrouwbaarheid onder extreme omstandigheden vereisen.

-

Chemische verwerkende industrie

- Componenten voor de productie van zwavelzuur (reactoren, warmtewisselaars), behandeling van zoutzuur (pompen, kleppen) en farmaceutische synthese (reactievaten).

-

Olie- en gasindustrie

- Werktuigen voor het afvoeren van water, componenten voor de boorkop en pijpleidingsonderdelen voor offshore- en zure gasomgevingen (weerstand biedt aan H2S en chloride-geïnduceerde SCC).

-

Milieutechniek

- Systemen voor ontzwaveling van rookgassen (FGD), afvalwaterzuiveringsapparatuur en verbrandingsinstallaties (bestaan tegen zure dampen en hoge temperaturen).

-

Luchtvaart en defensie

- Motorcomponenten, raketdüsen en militaire hardware (tolereren hoge temperatuur oxidatie en chemische blootstelling).

-

Andere sectoren met een hoge prestatie

- Kerncentralecomponenten (weerstand bieden aan door straling veroorzaakte afbraak), scheepsbouw (zeewaterbestendige bevestigingsstukken) en apparatuur voor de vervaardiging van halfgeleiders (vereisten inzake hoge zuiverheid).

![]()

![]()

![]()

![]()

Geadviseerde Producten