すべての製品

-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

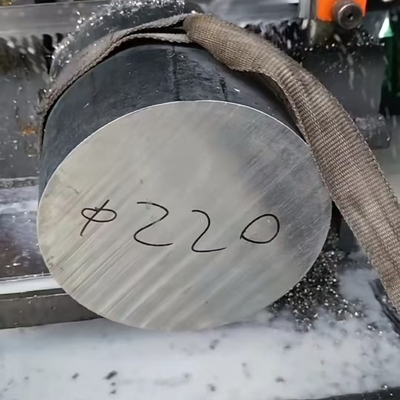

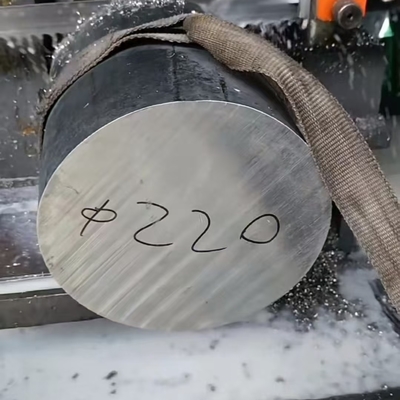

ホットロールニッケル合金丸棒 UNS N10276 / 2.4819 /合金C276丸棒 ASTM EN GB標準

商品の詳細

| 製品 | ニッケル合金板 | 学年 | c276 |

|---|---|---|---|

| 直径 | 6-350mm | 長さ | 要求に応じて任意の長さで切断 |

| 標準 | ASTM EN | サービス | 切断 |

| ロードポート | 上海港 | 表面 | 黒い,明るい |

| ハイライト | Hot Rolled Nickel Alloy Round Bar,UNS N10276 Round Rod,Alloy C276 ASTM Standard |

||

製品の説明

ホットロールニッケル合金丸棒 UNS N10276 / 2.4819 /合金C276丸棒 ASTM EN GB標準

速報

| グレード | ハステロイC276/24819 | 形状 | 丸いバー |

| 直径 | 6.0~350mm | タイプ | ホットロール,鍛造 |

| 長さ | オーダーメイド 要求に応じて任意の長さカット | 証明書 | EN 10204‐31 |

詳細情報

| 商品名 | ハステロイC276 丸い棒 |

| 直径 | 6.0~350mm |

| 長さ | 要求に応じて任意の長さのカスタムカット |

| 表面 | 黒い,明るい |

| ブランド | デルタ |

| サービス | 切る |

| MOQ | 2kg |

| 他のタイプ | 丸い棒,ストライプ,コイル,パイプ,シート,プレート,ワイヤ,など |

| 梱包 | 防水紙と木製パレット 木製の箱 |

| ロードポート | 上海港 |

| 価格期間 | EXW FOB CIF CFR |

| 配達時間 | 12日以内に |

合金C276 丸棒 ASTM EN GB規格

C276合金 (UNS N10276, Werkstoff Nr. 2.4819) は,最も厳しい産業環境における絶妙な耐腐蝕性で知られるニッケル・モリブデン・クロム・トルフスタン合金である.特に酸化や減量媒体を防げる熱巻き合金C276丸棒は,耐久性,化学的安定性,機械的強度が交渉できない重要なアプリケーションで広く使用されています.そのパラメータの包括的な概要は以下のとおりです生産プロセス,規格,同等品種,およびアプリケーション

1化学組成 (主要パラメータ)

C276合金 の 優れた性能 は,腐食 耐性 と 機械 特性 を バランス する 精密 に 制御 さ れ た 化学 組成 に よる もの です.典型的な組成物 (ASTM B574 による) は以下のとおりである.:

| エレメント | 含有範囲 (%) | 主要機能 |

|---|---|---|

| ニッケル (Ni) | ≥ 57 | 基本金属; 構造安定性と塩化物ストレス腐食破裂 (SCC) に抵抗性 |

| クロム (Cr) | 14.5から165 | 酸化媒介 (例えば,窒素酸,空気,海水) に対する耐性を高める |

| モリブデン (Mo) | 15.0から17まで0 | 減少媒体の耐性を向上させる (例えば硫酸,塩化水素酸) |

| タングスタン (W) | 30.0から4.5 | 穴 と 裂け目 の 腐食 に 耐久 性 を 向上 さ せる.合金 を 強化 する |

| 鉄 (Fe) | ≤ 50 | 柔らかさを維持しながら合金コストを削減します |

| 炭素 (C) | ≤0.01 | カービッド降水を最小限に抑える (高温での粒間腐食を避ける) |

| シリコン (Si) | ≤0.08 | 溶解中の酸化を制御し,不純物による脆さを制限する |

| マンガン (Mn) | ≤ 10 | ローリング中の熱加工性を向上させる |

| リンゴ (P) | ≤0.04 | 壊れやすいリスクを減らす |

| 硫黄 (S) | ≤0.03 | 製造中に裂け目を最小限に抑える |

2機械的・物理的特性

熱巻き合金C276丸棒は,高強度,柔性,熱安定性のユニークな組み合わせを示し,環境および高温アプリケーションの両方に適しています.

2.1 メカニカルプロパティ (ASTM B574 による熱巻き状態)

| 資産 | 試験基準 | 価値 (典型的な) | ユニット |

|---|---|---|---|

| 張力強度 (UTS) | ASTM E8 | ≥ 795 | MPa |

| 利回り強さ (0.2%オフセット) | ASTM E8 | ≥310 | MPa |

| 長さ (50mm) | ASTM E8 | ≥ 40 | % |

| 硬さ (ブリーネル) | ASTM E10 | ≤ 210 | HB |

注: 熱処理後 (例えば,溶液を1120°Cから1150°Cで焼却し,その後に迅速な冷却) は,残留ストレスを排除することで,強度と耐腐蝕性をさらに最適化することができる.

2.2 物理的特性

| 資産 | 価値 | ユニット |

|---|---|---|

| 密度 | 8.89 | g/cm3 |

| 溶解範囲 | 1325・1370 | °C |

| 熱伝導性 (25°C) | 10.8 | W/(m·K) |

| 熱膨張係数 (20~100°C) | 12.4 × 10−6 | /°C |

| 電気抵抗 (25°C) | 1.37 × 10−6 | オム |

3. 熱で巻きられたC276合金丸棒の製造プロセス

熱巻き合金C276丸棒の製造プロセスは,一貫性と性能を確保するために厳格な品質管理に従います.主なステップには以下が含まれます:

-

原材料の溶融と鋳造

- 高純度ニッケル,モリブデン,クロム,ウランは汚染を避けるために電弧炉 (EAF) や真空誘導溶融炉 (VIM) で溶かされる.

- 溶融合金は,直流鋳造または静流鋳造によって円筒状のブロック (ビレット) に鋳造され,直径は150mmから500mmまで.

-

均質化 焼却

- ビレットは1050~1100°Cに熱し,8~12時間保持し,化学分離をなくし,加工性を向上させる.

-

ホットローリング

- 焼却したビレットは1000~1100°C (合金最適熱加工温度範囲) に加熱され,一連のローリングミールを通過します.

- 切片の直径は,希望されたサイズ (一般直径:10mm~300mm) の丸い棒を形成するために徐々に縮小される.熱巻きは粒の構造と機械的強度を向上させる.

-

溶液 焼却 & 消化

- ローリング後,棒は30~60分間,1120~1150°Cで溶液焼却を受け,その後,水または空気で迅速に消化される.このステップでは,カービードと沉着物が溶け,最大の耐腐食性を回復する.

-

表面処理

- 鉄棒は,ローリング中に形成されたオキシド層を除去するために (窒素水素フッ素酸で漬け) 脱皮します.

- 任意の仕上げプロセス: 精密な寸法許容量 (例えば,h9/h10) と表面粗さ (Ra ≤ 6.3 μm) を達成するために磨き,磨き,または回転する.

-

品質検査

- 非破壊性試験 (NDT):内部欠陥の超音波試験 (UT),表面の裂け目の磁粒子試験 (MT).

- 化学組成分析 (光谱分析,OES),機械性能試験 (張力,硬さ),次元検証.

4国際基準

合金C276の丸い棒は,産業間での相互運用性を確保するために,世界標準に従って製造され,検査されます.最も広く認識されている規格は,以下です.

| 標準システム | 標準番号 | 仕様の適用範囲 |

|---|---|---|

| ASTM (アメリカ) | ASTMB574 | ニッケル・クロム・モリブデン・タングスタム合金 (UNS N10276) の棒および棒に関する標準仕様 |

| EN (ヨーロッパ) | EN 10088-3 | 耐熱鋼 部分3:鋳造品 (合金2.4819) |

| GB (中国) | GB/T 2054 | ニッケルとニッケル合金製の棒と棒 (同等級:N06276) |

| ISO | ISO 6208 | ニッケルとニッケル合金 (C276合金に関する一般要件) の棒と棒 |

5同等級

合金C276は,世界中で異なる指定の下で標準化されています.これらのグレードは,ほぼ同一の化学的組成と性能を有し,国境を越えたプロジェクトで互換性を確保します:

| 標準システム | 級別指定 | 合金 |

|---|---|---|

| UNS (アメリカ) | UNS N10276 | 合金C276 |

| DIN/EN (ヨーロッパ) | 素材24819 | 合金C276 |

| GB (中国) | N06276 について | 合金C276 |

| JIS (日本) | NW2276 | 合金C276 |

| BS (イギリス) | NA 21 | 合金C276 |

6申請について

合金C276の丸い棒は,極端な条件下で優れた耐腐蝕性および機械的信頼性を要求する産業で好まれている.典型的用途には以下が含まれます.

-

化学加工産業

- 硫酸の生産 (反応器,熱交換器),塩化酸の処理 (ポンプ,バルブ),医薬品合成 (反応容器) の部品.

-

石油・ガス産業

- 掘削ツール,井戸頭部品,海上および酸性ガス環境のためのパイプライン部品 (H2Sと塩化物によるSCCに耐える)

-

環境工学

- 煙草ガス脱硫 (FGD) システム,廃水処理設備,焼却炉部品 (酸性煙と高温に耐える)

-

航空宇宙・防衛

- エンジン部品,ロケットノズル,軍用ハードウェア (高温酸化と化学的暴露に耐える)

-

他の高性能セクター

- 原子力発電所の部品 (放射線による劣化に耐える),船舶工学 (海水耐性固定材),半導体製造機器 (高純度要求)

![]()

![]()

![]()

![]()

推薦されたプロダクト