-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

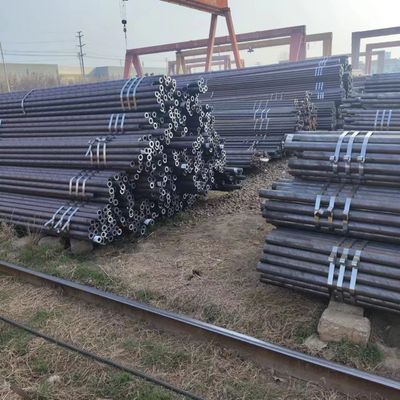

ASTM JIS GB EN DIN Carbon Steel Pipe AISI1045 S45C 45# Steel Seamless Pipe

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | Carbon Steel , Alloy Steel |

| Minimum Order Quantity | 4 Tons |

| Price | 610 - 820 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 10 days based on the quantity |

| Payment Terms | L/C, Western Union, T/T |

| Supply Ability | 20Ton per week |

| Products | Seamless Steel Pipe | Diameter | DN10 - DN600 |

|---|---|---|---|

| Thickness | 1.0 - 50.0mm | Length | 6-10m Or Cutting As Request |

| Standard | ASTM EN GB DIN | Technique | Hot Rolled |

| Service | Cutting Any Length As Request | MOQ | 2 Ton |

| Highlight | 45# Carbon Steel Pipe,AISI1045 Carbon Steel Pipe,S45C Carbon Steel Pipe |

||

ASTM JIS GB EN DIN Carbon Steel Pipe AISI1045 S45C 45# Steel Seamless Pipe

AISI 1045 Tube Specifications and Thickness

| Name | SAE1045 Hot Rolled Seamless Steel Pipe |

| Surface | Bare,oiled |

| Material | ASTM A106B, ASTM A53B, API 5L Gr.B, ST52, ST37, ST44 SAE1010/1020/1045,S45C/CK45,SCM435,AISI4130/4140 |

| MOQ | 5 tons for normal size and material |

| WT | As customer's requests |

| Payment terms | TT deposit + the balanced against BL copy / LC or 100% LC at sight |

| Trade terms | FOB,C&F,CIF,EXW |

| Length | fixed or random,as customer request. |

| End Treatment | Plain(can be beveled, threaded,punch,shrink,extension... ) |

| Lead time | within 7 days from stock with 6m length (stock pipe with our factory name in Chinese),20-25 days for customized pipe according to the qty |

What Is the Carbon Content of 1045 Carbon Steel?

Medium-carbon steel like 1045 has a carbon content of roughly 0.45%. The amount of carbon in plain carbon steels is a key factor in determining their strength and mechanical characteristics. With a good balance of strength and toughness, 1045 steel can be heat-treated to harden due in part to the carbon content. Due to its medium-carbon composition, the specific mechanical properties of 1045 steel fall within the mid-range.

What Are the Properties of 1045 Carbon Steel?

Table 2 summarizes the properties of 1045 carbon steel:

| Property | Value |

|---|---|

|

Density

|

7.87 g/cm³

|

|

Yield Strength

|

450-560 MPa

|

|

Hardness

|

170-210 HB

|

|

Magnetism

|

Magnetic

|

|

Tensile strength

|

570 - 700 Mpa

|

|

Elongation at break (in 50mm)

|

16.00%

|

|

Electrical conductivity

|

6.17×106

|

Machinability Rating of 1045 Carbon Steel

Steel, a versatile material, exhibits varying machinability based on its carbon content. Optimal machinability is achieved with medium carbon amounts, approximately 0.20%. For instance, 1045 carbon steel, which falls within this range, possesses a machinability rating of approximately 65% in its annealed condition. This rating reflects the favorable machinability characteristics of 1045 steel, categorizing it as a material with good machinability. To achieve the best machining results, AISI 1045 steel must undergo the proper heat treatment. Machinability can be impacted by a history of cold work or heat treatment.

What Are the Thermal Properties of 1045 Carbon Steel?

The thermal properties of 1045 carbon steel include a thermal conductivity of approximately 51.9 W/m·K and a specific heat capacity of around 486 J/kg·K. These properties determine how the material conducts and stores heat. With its relatively high thermal conductivity compared to 304 stainless steel (16.8 W/(m·k)), AISI 1045 steel is efficient in transferring heat. This makes it suitable for applications that involve heat dissipation or thermal management. The specific heat capacity indicates the amount of heat energy required to raise the temperature of the material one degree Celsius. Table 3 shows these properties at a glance:

| Property | Value |

|---|---|

|

Thermal Conductivity

|

51.9 W/m·K

|

|

Specific Heat Capacity

|

486 J/kg·K

|

|

Melting Point

|

1510 °C (2750 °F)

|

What Are the Common Forms of Our 1045 Carbon Steel Material?

The common forms of 1045 carbon steel material include sheet, bar, plate, hot rolled, annealed, and cold drawn variants. These are described below:

Sheet

1045 steel sheet is a thin and flat form with moderate strength, good machinability, and moderate weldability. It typically contains around 0.45% carbon, along with manganese, phosphorus, sulfur, and other trace elements. Its annealed microstructure consists of ferrite and pearlite, offering strength and toughness. 1045 steel sheet is used in manufacturing, automotive, construction, toolmaking, agriculture, industrial machinery, and oil and gas industries.

Bar

The strength, machinability, and wear resistance of the 1045 carbon steel bar are primarily determined by its composition and metallurgical properties, rather than its shape. However, the solid, cylindrical shape of the bar is widely recognized for facilitating efficient handling, machining, and installation processes. In summary, while the shape itself does not directly influence the mentioned properties, the cylindrical form of the 1045 carbon steel bar offers practical advantages in various applications. Ferrite and pearlite make up its annealed microstructure, which gives the material strength and toughness. Shafts, gears, bolts, studs, and other machinery parts are merely a few instances of the bar's numerous uses.

Plate

The main distinction between steel plates and steel bars lies in their sizes. Steel products that are more than 8 inches wide are classified as plate products, while those less than 8 inches wide are considered flat bar products. Both 1045 carbon steel plate and bar refer to specific types of steel made from carbon with the designation "1045," indicating its carbon content. 1045 has high strength, good machinability, and moderate weldability. AISI 1045 is a plain carbon steel containing 0.45% carbon, 0.45% manganese, 0.45% phosphorus, 0.45% sulfur, and other trace elements. Its ferrite and pearlite annealed microstructure contribute to good toughness and impact resistance. Construction equipment, industrial machinery parts, and machinery frames are common uses for 1045 carbon steel plates.

Hot Rolled

Hot rolling is a manufacturing process employed in various industries to produce hot-rolled 1045 carbon steel. This process results in a scaled surface finish. Hot-rolled 1045 steel exhibits enhanced ductility, toughness, and machinability in comparison to cold-drawn or cold-rolled forms. Industries such as automotive, construction, and machinery utilize hot-rolled 1045 steel for the production of shafts, gears, axles, and structural components.

Annealed

Annealing is a heat treatment process that aims to modify the microstructure and grain size of a material. By heating the material to a specific temperature, crystallization occurs, resulting in larger grain sizes. If the material was in the martensite phase before annealing, it will no longer be in that phase afterward. However, the distribution of pearlite and ferrite may vary while the overall amounts remain unchanged. Among various heat treatment techniques, annealing is popular due to its ability to increase ductility and reduce hardness. When 1045 carbon steel is annealed, it undergoes heat treatment to relieve internal stresses and improve machinability. In its annealed state, the steel exhibits enhanced machinability, improved dimensional stability, and reduced hardness.

Cold Drawn

1045 carbon steel that has been cold drawn or cold worked experiences plastic deformation above the temperature of recrystallization, which causes strain hardening. Compared to the annealed state, this decreases ductility while increasing yield and ultimate tensile strength. Cold-drawn 1045 steel has a deformed microstructure despite being primarily ferrite and pearlite. This manufacturing process improves mechanical properties, surface quality, and dimensional accuracy, making it suitable for applications that call for high strength, tight tolerances, and excellent surface quality, such as automotive parts, shafts, and precise machinery components.

What Are Equivalents of 1045 Carbon Steel?

Table 4 shows equivalent grades for AISI 1045 carbon steel in the naming systems:

| Country | Equivalent Name |

|---|---|

|

United States

|

AISI 1045

|

|

European Union

|

C45E or Ck45

|

|

Germany

|

1.1191 or C45E

|

|

United Kingdom

|

080M46 or 43A

|

|

Japan

|

S45C or S48C

|

|

China

|

45# or 45B

|

What Are the Advantages of Using 1045 Carbon Steel?

The advantages of using 1045 carbon steel include:

- Offers excellent tensile strength and hardness, making it suitable for demanding applications.

- It can be easily machined into various shapes and forms, allowing for efficient manufacturing processes.

- When techniques for joining medium-carbon steels are used, AISI 1045 is suitable for welding.

- 1045 carbon steel is known for its ferrite and pearlite microstructure, which consists of alternating lamellae of ferrite and cementite (iron carbide). This unique structure contributes to its wear-resistance properties. The carbides present in the pearlite structure are responsible for providing enhanced wear resistance, making 1045 carbon steel suitable for components subjected to wear and friction.

What Are the Disadvantages of Using 1045 Carbon Steel?

While 1045 carbon steel offers many benefits, there are a few disadvantages to consider:

- It is not highly resistant to corrosion, especially in harsh environments. It may require additional protective coatings or maintenance to prevent corrosion.

- It has a limited ability to be hardened through heat treatment compared to some other steel grades. This can limit its use in applications where high hardness is required.

- Improper heat treatment or welding techniques can lead to cracking or distortion in 1045 carbon steel components.

- While 1045 carbon steel is not considered a high-cost material compared to some specialty steels, it can be more expensive than lower-grade carbon steels. The cost of steel depends on various factors such as the quality, availability, market demand, and the specific requirements of a project.

What Is the Difference Between 1045 Carbon Steel and A514 Steel?

The difference between 1045 carbon steel and A514 steel (also called “T1”) lies in their composition and strength. While A514 steel, a high-strength, low-alloy steel, contains specific alloying elements such as carbon, chromium, and manganese. It is often employed in structural applications due to its higher strength and hardness, 1045 carbon steel, which has 0.45% carbon, is used for general-purpose applications.

![]()

![]()

![]()

![]()