Tutti i prodotti

-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

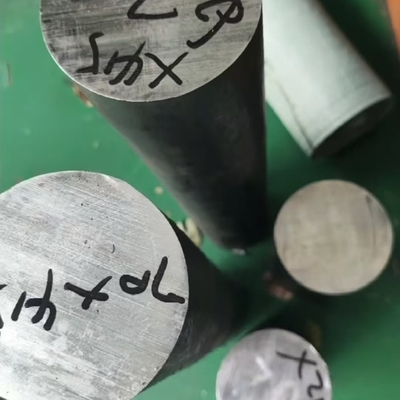

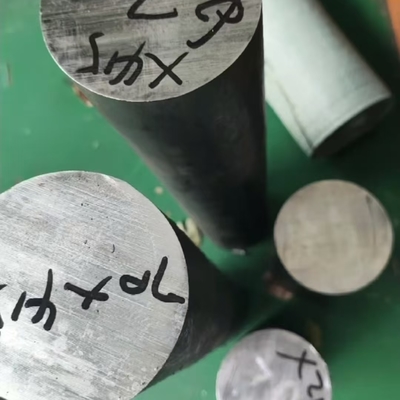

Hastelloy C276 / Lega 2.4819 Lega di nichel Bar / disco / cerchio rotondo laminato a caldo e forgiato

| Luogo di origine | Cina |

|---|---|

| Marca | DELTA |

| Certificazione | ISO |

| Numero di modello | c276 |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 40-45 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 3 tonnellate a settimana |

Dettagli

| Prodotti | Placca in lega di nichel | Grado | c276 |

|---|---|---|---|

| Diametro | 6 - 350 mm | Lunghezza | taglio su misura di qualsiasi lunghezza su richiesta |

| Standard | Astm en | Servizio | Taglio |

| Porta di caricamento | Shanghai Port | Superficie | nero, luminoso |

| Evidenziare | Hastelloy C276 round bar,Alloy 2.4819 forged rod,Nickel alloy hot rolled disc |

||

Descrizione di prodotto

Barra tonda / Disco / Cerchio in lega di nichel Hastelloy C276 / Lega 2.4819 laminata a caldo e forgiata C276

Informazioni rapide

| Grado | Hastelloy C276 / 2.4819 | Forma | Barra tonda |

| Diametro | 6.0 - 350mm | Tipo | Laminato a caldo, forgiato |

| Lunghezza | Taglio personalizzato di qualsiasi lunghezza su richiesta | Certificato | EN 10204-3.1 |

Maggiori informazioni sulle specifiche

| Nome dei prodotti | Barra tonda / Rod Hastelloy C276 |

| Diametro | 6.0 - 350mm |

| Lunghezza | taglio personalizzato di qualsiasi lunghezza su richiesta |

| Superficie | Nero, lucido |

| Marchio | DELTA |

| Servizio | taglio |

| MOQ | 2 Kg |

| Altro tipo | barra tonda, striscia, bobina, tubo.foglio, piastra, filo.ecc |

| Imballaggio | carta impermeabile e pallet di legno, scatola di legno |

| Porto di carico | Porto di Shanghai |

| Termine di prezzo | EXW, FOB, CIF, CFR |

| Tempo di consegna | entro 12 giorni |

Barra tonda / Disco / Cerchio in lega di nichel Hastelloy C276 / Lega 2.4819 laminata a caldo e forgiata C276

L'Hastelloy C276 (UNS N10276, W. Nr. 2.4819) è una lega di nichel-molibdeno-cromo di alta qualità, rinomata per la sua eccezionale resistenza alla corrosione in ambienti aggressivi, in particolare contro i mezzi ossidanti e riducenti. Le barre tonde, i dischi e i cerchi laminati a caldo e forgiati di questa lega sfruttano processi di produzione ottimizzati per migliorare la resistenza meccanica, l'integrità strutturale e la precisione dimensionale, rendendoli ideali per applicazioni industriali critiche in cui l'affidabilità e la durata sono imprescindibili.

1. Composizione chimica (parametri chiave)

Le prestazioni superiori dell'Hastelloy C276 derivano dalla sua composizione chimica controllata con precisione, che bilancia il nichel (l'elemento base) con elementi di lega per resistere alla corrosione e mantenere la stabilità meccanica. Di seguito è riportata la composizione tipica secondo gli standard internazionali:

| Elemento | Intervallo di contenuto (%) | Funzione |

|---|---|---|

| Nichel (Ni) | 54.0 - 60.0 | Metallo base; fornisce duttilità, tenacità e resistenza alla tensocorrosione |

| Cromo (Cr) | 14.5 - 16.5 | Migliora la resistenza all'ossidazione e agli acidi solforico/nitrico |

| Molibdeno (Mo) | 15.0 - 17.0 | Fondamentale per la resistenza ai mezzi riducenti (ad es. acido cloridrico) e alla corrosione per vaiolatura |

| Tungsteno (W) | 3.0 - 4.5 | Completa il molibdeno per aumentare la resistenza alla corrosione interstiziale e all'attacco localizzato |

| Ferro (Fe) | ≤ 5.0 | Migliora la lavorabilità durante la laminazione/forgiatura a caldo senza compromettere la resistenza alla corrosione |

| Carbonio (C) | ≤ 0.010 | Minimizzato per prevenire la precipitazione di carburi (evita la corrosione intergranulare ad alte temperature) |

| Silicio (Si) | ≤ 0.08 | Controlla la formazione di ossidi e migliora la qualità della fusione/forgiatura |

| Manganese (Mn) | ≤ 1.0 | Aiuta nella disossidazione durante la produzione; mantiene la duttilità della lega |

| Fosforo (P) | ≤ 0.040 | Limitato per evitare la fragilità e ridurre i rischi di corrosione |

| Zolfo (S) | ≤ 0.030 | Minimizzato per prevenire le cricche a caldo durante la forgiatura e migliorare la resistenza alla corrosione |

2. Proprietà meccaniche e fisiche

Le barre tonde Hastelloy C276 laminate a caldo e forgiate mostrano proprietà meccaniche migliorate rispetto alle varianti fuse o lavorate a freddo, grazie alla raffinazione della grana durante la lavorazione termica.

2.1 Proprietà meccaniche (valori tipici per barre laminate a caldo/forgiate, condizione ricotta)

| Proprietà | Unità | Valore (ricotto, 25°C/77°F) |

|---|---|---|

| Resistenza alla trazione (UTS) | MPa | ≥ 790 |

| Limite di snervamento (0,2% di offset) | MPa | ≥ 380 |

| Allungamento (in 50 mm) | % | ≥ 40 |

| Durezza (Brinell, HB) | - | ≤ 210 |

| Resistenza all'urto (Charpy V-Notch) | J | ≥ 100 (a 25°C) |

2.2 Proprietà fisiche

| Proprietà | Unità | Valore (a 25°C/77°F se non diversamente indicato) |

|---|---|---|

| Densità | g/cm³ | 8.89 |

| Intervallo di fusione | °C | 1325 - 1370 |

| Conducibilità termica | W/(m·K) | 11.8 (a 100°C) |

| Coefficiente di espansione termica (CTE) | μm/(m·K) | 12.4 (20 - 100°C) |

| Resistività elettrica | Ω·mm²/m | 1.37 |

| Modulo di elasticità | GPa | 205 |

3. Processo di fabbricazione: laminato a caldo vs. forgiato

I processi di laminazione a caldo e forgiatura sono fondamentali per ottimizzare le prestazioni delle barre tonde Hastelloy C276:

-

Barre tonde laminate a caldo: prodotte riscaldando la billetta in lega a 1150 - 1250°C (al di sopra della sua temperatura di ricristallizzazione) e laminandola attraverso matrici successive per ottenere il diametro desiderato (tipicamente 6 mm - 300 mm). Questo processo migliora la duttilità, affina la struttura della grana e garantisce un'accuratezza dimensionale uniforme. Le barre laminate a caldo sono convenienti per applicazioni standard.

-

Barre tonde/dischi/cerchi forgiati: prodotti applicando un'elevata pressione a billette riscaldate (1100 - 1200°C) utilizzando presse o martelli, modellandoli in tondini, dischi (spessore: 10 mm - 500 mm; diametro: 50 mm - 1000 mm) o cerchi. La forgiatura elimina i difetti interni (ad es. porosità), migliora la resistenza meccanica (in particolare la tenacità all'urto) e allinea il flusso della grana con la direzione di sollecitazione della parte. I prodotti forgiati sono preferiti per applicazioni ad alta pressione e alta temperatura (HPHT).

4. Standard e specifiche internazionali

Le barre tonde, i dischi e i cerchi Hastelloy C276 sono conformi agli standard riconosciuti a livello globale per garantire coerenza e qualità:

| Organizzazione standard | Numero standard | Ambito di applicazione |

|---|---|---|

| ASTM International | ASTM B574 | Barra, barra e filo in lega di nichel (standard primario per barre laminate a caldo/forgiate) |

| ASTM International | ASTM B622 | Piastra, lamiera e nastro in lega di nichel (riferimento per dischi/cerchi) |

| ASME | ASME SB574 | Codice per caldaie e recipienti a pressione (per applicazioni HPHT) |

| DIN (Germania) | DIN EN 10095 | Acciai resistenti al calore e leghe di nichel (include 2.4819) |

| ISO | ISO 9723 | Nichel e leghe di nichel — Tondini e barre |

| JIS (Giappone) | JIS H4551 | Barre in nichel e leghe di nichel |

5. Gradi equivalenti

Hastelloy C276 è commercializzato con diverse designazioni in tutto il mondo, a seconda degli standard regionali. Di seguito sono riportati i suoi gradi equivalenti chiave:

| Sistema regionale | Designazione del grado | Standard corrispondente |

|---|---|---|

| UNS (USA) | N10276 | ASTM B574, ASME SB574 |

| W. Nr. (Germania) | 2.4819 | DIN EN 10095, DIN 17750 |

| BS (Regno Unito) | NA 44 | BS 3074 (Parte 3) |

| JIS (Giappone) | NW 276 | JIS H4551 |

| GOST (Russia) | KhN68MVTYu | GOST 9668 |

| EN (Europa) | NiCr21Mo14W | EN 10095 |

6. Principali vantaggi prestazionali

Le barre tonde Hastelloy C276 si distinguono per la loro combinazione unica di proprietà, che le rendono superiori a molte altre leghe di nichel:

- Eccezionale resistenza alla corrosione: resiste sia ai mezzi ossidanti (ad es. acido nitrico, acqua di mare) che a quelli riducenti (ad es. acido cloridrico, acido solforico). Resiste anche alla vaiolatura, alla corrosione interstiziale e alla tensocorrosione (SCC) in ambienti ricchi di cloruri.

- Stabilità alle alte temperature: mantiene la resistenza meccanica e la resistenza alla corrosione fino a 1093°C (2000°F), rendendolo adatto per applicazioni ad alta temperatura (ad es. componenti di forni).

- Eccellente fabbricabilità: le varianti laminate a caldo e forgiate offrono una buona duttilità, consentendo la piegatura, la saldatura e la lavorazione (con utensili in metallo duro) per soddisfare i requisiti di parti personalizzate.

- Bassa precipitazione di carburi: il basso contenuto di carbonio riduce al minimo la formazione di carburi di cromo durante la saldatura o il trattamento termico, eliminando i rischi di corrosione intergranulare.

7. Applicazioni

Le barre tonde, i dischi e i cerchi Hastelloy C276 sono ampiamente utilizzati nei settori in cui la resistenza alla corrosione e le prestazioni alle alte temperature sono fondamentali:

- Trasformazione chimica: reattori, scambiatori di calore, valvole e alberi di pompe (per la manipolazione di acidi, solventi e fanghi corrosivi).

- Petrolio e gas: componenti di fondo pozzo, apparecchiature per la testa di pozzo e sistemi di tubazioni (resiste a gas acidi, salamoie e corrosione indotta da cloruri).

- Industria farmaceutica e alimentare: recipienti, miscelatori e raccordi sanitari (conformi agli standard FDA; resiste agli agenti di pulizia e ai processi di sterilizzazione).

- Aerospaziale e difesa: camere di combustione dei motori a reazione, pale di turbine e componenti di missili (resiste al calore elevato e ai carburanti aggressivi).

- Ingegneria ambientale: sistemi di desolforazione dei fumi (FGD), apparecchiature per il trattamento delle acque reflue e parti di inceneritori (resiste ai fumi acidi e alle sostanze chimiche tossiche).

- Generazione di energia: tubi di caldaia, turbine a vapore e componenti di centrali nucleari (gestisce alta pressione, alta temperatura e corrosione del refrigerante).

![]()

![]()

![]()

![]()

Prodotti raccomandati