모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

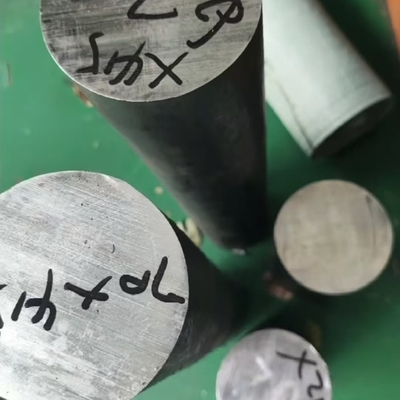

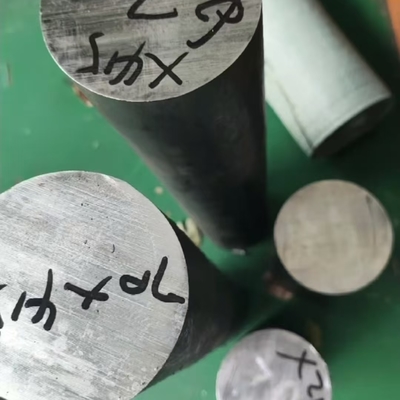

하스텔로이 C276 / 합금 2.4819 니켈 합금 둥근 막대 / 디스크 / 원 핫 롤링 및 조형 C276 둥근 막대

제품 상세 정보

| 제품 | 니켈 합금판 | 등급 | c276 |

|---|---|---|---|

| 지름 | 6-350mm | 길이 | 요청에 따라 모든 길이를 커스터마 절단합니다 |

| 기준 | astm en | 서비스 | 절단 |

| 로딩 포트 | 상하이 항구 | 표면 | 검은색, 밝은 |

| 강조하다 | Hastelloy C276 round bar,Alloy 2.4819 forged rod,Nickel alloy hot rolled disc |

||

제품 설명

Hastelloy C276 / 합금 2.4819 니켈 합금 원형 바 / 디스크 / 원형 열간 압연 및 단조 C276 원형 로드

빠른 정보

| 등급 | Hastelloy C276 / 2.4819 | 모양 | 원형 바 |

| 직경 | 6.0 - 350mm | 유형 | 열간 압연, 단조 |

| 길이 | 요청에 따라 모든 길이로 맞춤 절단 | 인증서 | EN 10204-3.1 |

추가 사양 정보

| 제품 이름 | Hastelloy C276 원형 바 / 로드 |

| 직경 | 6.0 - 350mm |

| 길이 | 요청에 따라 모든 길이로 맞춤 절단 |

| 표면 | 검정색, 밝은색 |

| 브랜드 | DELTA |

| 서비스 | 절단 |

| MOQ | 2 Kgs |

| 기타 유형 | 원형 바, 스트립, 코일, 파이프, 시트, 플레이트, 와이어 등 |

| 포장 | 방수 종이 및 나무 팔레트, 나무 상자 |

| 적재 항구 | 상하이 항구 |

| 가격 조건 | EXW, FOB, CIF, CFR |

| 배송 시간 | 12일 이내 |

Hastelloy C276 / 합금 2.4819 니켈 합금 원형 바 / 디스크 / 원형 열간 압연 및 단조 C276 원형 로드

Hastelloy C276 (UNS N10276, W. Nr. 2.4819)는 특히 산화성 및 환원성 매체에 대한 가혹한 환경에서 뛰어난 내식성으로 유명한 프리미엄 니켈-몰리브덴-크롬 합금입니다. 이 합금의 열간 압연 및 단조 원형 바, 디스크 및 원형은 최적화된 제조 공정을 활용하여 기계적 강도, 구조적 무결성 및 치수 정밀도를 향상시켜 신뢰성과 내구성이 필수적인 중요한 산업 응용 분야에 이상적입니다.

1. 화학 조성 (주요 매개변수)

Hastelloy C276의 우수한 성능은 니켈(기본 원소)을 합금 원소와 정확하게 제어된 화학 조성으로 균형을 이루어 부식에 저항하고 기계적 안정성을 유지하는 데서 비롯됩니다. 다음은 국제 표준에 따른 일반적인 조성입니다.

| 원소 | 함량 범위 (%) | 기능 |

|---|---|---|

| 니켈 (Ni) | 54.0 - 60.0 | 기본 금속; 연성, 인성 및 응력 부식 균열 저항 제공 |

| 크롬 (Cr) | 14.5 - 16.5 | 산화 저항 및 황산/질산 저항 향상 |

| 몰리브덴 (Mo) | 15.0 - 17.0 | 환원성 매체(예: 염산) 및 핏팅 부식에 대한 저항에 중요 |

| 텅스텐 (W) | 3.0 - 4.5 | 몰리브덴을 보완하여 틈새 부식 및 국부적 공격에 대한 저항력 향상 |

| 철 (Fe) | ≤ 5.0 | 부식 저항을 손상시키지 않으면서 열간 압연/단조 시 가공성 향상 |

| 탄소 (C) | ≤ 0.010 | 탄화물 석출 방지 (고온에서 입계 부식 방지)를 위해 최소화 |

| 실리콘 (Si) | ≤ 0.08 | 산화물 형성을 제어하고 주조/단조 품질 향상 |

| 망간 (Mn) | ≤ 1.0 | 제조 중 탈산에 도움; 합금 연성 유지 |

| 인 (P) | ≤ 0.040 | 취성을 방지하고 부식 위험을 줄이기 위해 제한 |

| 황 (S) | ≤ 0.030 | 단조 중 핫 크래킹을 방지하고 부식 저항을 향상시키기 위해 최소화 |

2. 기계적 및 물리적 특성

열간 압연 및 단조 Hastelloy C276 원형 바는 열처리 공정 중 결정립 미세화 덕분에 주조 또는 냉간 가공 변형체에 비해 향상된 기계적 특성을 나타냅니다.

2.1 기계적 특성 (열간 압연/단조 바, 어닐링 상태의 일반적인 값)

| 특성 | 단위 | 값 (어닐링, 25°C/77°F) |

|---|---|---|

| 인장 강도 (UTS) | MPa | ≥ 790 |

| 항복 강도 (0.2% 오프셋) | MPa | ≥ 380 |

| 신율 (50mm) | % | ≥ 40 |

| 경도 (브리넬, HB) | - | ≤ 210 |

| 충격 인성 (샤르피 V-노치) | J | ≥ 100 (25°C) |

2.2 물리적 특성

| 특성 | 단위 | 값 (별도로 명시되지 않는 한 25°C/77°F) |

|---|---|---|

| 밀도 | g/cm³ | 8.89 |

| 융점 범위 | °C | 1325 - 1370 |

| 열전도율 | W/(m·K) | 11.8 (100°C) |

| 열팽창 계수 (CTE) | μm/(m·K) | 12.4 (20 - 100°C) |

| 전기 저항 | Ω·mm²/m | 1.37 |

| 탄성 계수 | GPa | 205 |

3. 제조 공정: 열간 압연 vs. 단조

열간 압연 및 단조 공정은 Hastelloy C276 원형 바의 성능을 최적화하는 데 중요합니다.

-

열간 압연 원형 바: 합금 빌렛을 1150 - 1250°C(재결정 온도 이상)로 가열하고 원하는 직경(일반적으로 6mm - 300mm)을 얻기 위해 연속 다이를 통해 압연하여 생산됩니다. 이 공정은 연성을 향상시키고, 결정립 구조를 미세화하며, 균일한 치수 정확도를 보장합니다. 열간 압연 바는 표준 응용 분야에 비용 효율적입니다.

-

단조 원형 바/디스크/원형: 가열된 빌렛(1100 - 1200°C)에 프레스 또는 해머를 사용하여 고압을 가하여 원형 로드, 디스크(두께: 10mm - 500mm; 직경: 50mm - 1000mm) 또는 원형으로 성형하여 제조됩니다. 단조는 내부 결함(예: 다공성)을 제거하고, 기계적 강도(특히 충격 인성)를 향상시키며, 결정립 흐름을 부품의 응력 방향에 맞춥니다. 단조 제품은 고압, 고온(HPHT) 응용 분야에 선호됩니다.

4. 국제 표준 및 사양

Hastelloy C276 원형 바, 디스크 및 원형은 일관성과 품질을 보장하기 위해 전 세계적으로 인정된 표준을 준수합니다.

| 표준 기관 | 표준 번호 | 응용 범위 |

|---|---|---|

| ASTM International | ASTM B574 | 니켈 합금 로드, 바 및 와이어(열간 압연/단조 바에 대한 기본 표준) |

| ASTM International | ASTM B622 | 니켈 합금 플레이트, 시트 및 스트립(디스크/원형 참조) |

| ASME | ASME SB574 | 보일러 및 압력 용기 코드(HPHT 응용 분야) |

| DIN (독일) | DIN EN 10095 | 내열강 및 니켈 합금(2.4819 포함) |

| ISO | ISO 9723 | 니켈 및 니켈 합금 — 로드 및 바 |

| JIS (일본) | JIS H4551 | 니켈 및 니켈 합금 바 |

5. 등급 동등성

Hastelloy C276은 지역 표준에 따라 전 세계적으로 다른 명칭으로 판매됩니다. 다음은 주요 등급 동등성입니다.

| 지역 시스템 | 등급 지정 | 해당 표준 |

|---|---|---|

| UNS (미국) | N10276 | ASTM B574, ASME SB574 |

| W. Nr. (독일) | 2.4819 | DIN EN 10095, DIN 17750 |

| BS (영국) | NA 44 | BS 3074 (Part 3) |

| JIS (일본) | NW 276 | JIS H4551 |

| GOST (러시아) | KhN68MVTYu | GOST 9668 |

| EN (유럽) | NiCr21Mo14W | EN 10095 |

6. 주요 성능 장점

Hastelloy C276 원형 바는 고유한 특성 조합으로 인해 다른 많은 니켈 합금보다 우수합니다.

- 뛰어난 내식성: 산화성(예: 질산, 해수) 및 환원성(예: 염산, 황산) 매체에 모두 저항합니다. 또한 염화물 함량이 높은 환경에서 핏팅, 틈새 부식 및 응력 부식 균열(SCC)에 견딥니다.

- 고온 안정성: 최대 1093°C(2000°F)까지 기계적 강도와 내식성을 유지하여 고열 응용 분야(예: 용광로 부품)에 적합합니다.

- 우수한 가공성: 열간 압연 및 단조 변형체는 우수한 연성을 제공하여 맞춤형 부품 요구 사항을 충족하기 위해 굽힘, 용접 및 가공(탄화물 공구 사용)을 할 수 있습니다.

- 낮은 탄화물 석출: 낮은 탄소 함량은 용접 또는 열처리 중 크롬 탄화물 형성을 최소화하여 입계 부식 위험을 제거합니다.

7. 응용 분야

Hastelloy C276 원형 바, 디스크 및 원형은 내식성과 고온 성능이 중요한 산업 분야에서 널리 사용됩니다.

- 화학 처리: 반응기, 열교환기, 밸브 및 펌프 샤프트(산, 용매 및 부식성 슬러리 취급용).

- 석유 및 가스: 유정 내 부품, 웰헤드 장비 및 파이프라인 시스템(신 가스, 염수 및 염화물 유도 부식에 저항).

- 제약 및 식품 가공: 용기, 믹서 및 위생 설비(FDA 표준 준수; 세척제 및 살균 공정에 저항).

- 항공 우주 및 방위: 제트 엔진 연소실, 터빈 블레이드 및 미사일 부품(고열 및 공격적인 연료에 견딤).

- 환경 공학: 배가스 탈황(FGD) 시스템, 폐수 처리 장비 및 소각로 부품(산성 배가스 및 유독성 화학 물질에 저항).

- 발전: 보일러 튜브, 증기 터빈 및 원자력 발전소 부품(고압, 고온 및 냉각수 부식 처리).

![]()

![]()

![]()

![]()

추천된 제품