Alle Produkte

-

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

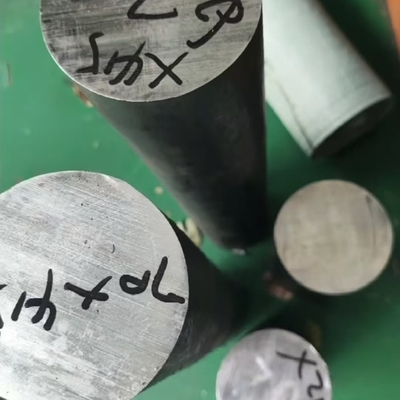

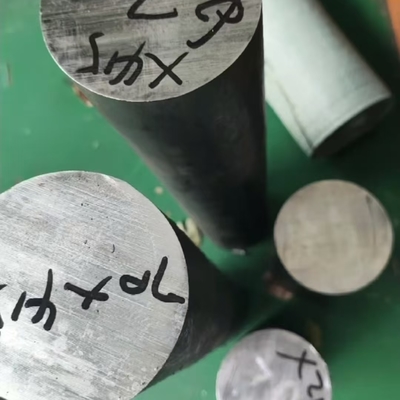

Hastelloy C276 / Legierung 2.4819 Nickellegierungs-Rundstab / -Scheibe / -Kreis warmgewalzt und geschmiedet C276 Rundstab

| Herkunftsort | China |

|---|---|

| Markenname | DELTA |

| Zertifizierung | ISO |

| Modellnummer | c276 |

| Min Bestellmenge | 500 kg |

| Preis | 40-45 USD/Kg |

| Verpackung Informationen | Standardverpackung für den Exportieren |

| Lieferzeit | 5 - 12 Tage basierend auf der Menge |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 3 Tonnen pro Woche |

Produktdetails

| Produkte | Platten aus Nickellegierungen | Grad | c276 |

|---|---|---|---|

| Durchmesser | 6 - 350 mm | Länge | Auf Wunsch beliebige Schnittlängen |

| Standard | ASTM EN | Service | Schneiden |

| Ladeanschluss | Shanghai Hafen | Oberfläche | Schwarz, hell |

| Hervorheben | Hastelloy C276 round bar,Alloy 2.4819 forged rod,Nickel alloy hot rolled disc |

||

Produkt-Beschreibung

Hastelloy C276 / Legierung 2.4819 Nickellegierung Rundbar / Scheibe / Kreis Warmgewalzt und geschmiedet

Schnelle Informationen

| Zulassung | Hastelloy C276 / 2.4819 | Form | Runde Stange |

| Durchmesser | 6.0 - 350 mm | Typ | Warmgewalzt, geschmiedet |

| Länge | Auf Wunsch beliebige Länge schneiden | Bescheinigung | EN 10204-3.1 |

Weitere Spezifikationen

| Produktbezeichnung | Hastelloy C276 Runde Stange |

| Durchmesser | 6.0 - 350 mm |

| Länge | Auf Wunsch beliebige Schnittlängen |

| Oberfläche | Schwarz, hell. |

| Marke | DELTA |

| Dienstleistungen | Schneiden |

| MOQ | 2 kg |

| Andere Typen | Rundbar, Streifen,Spule,Rohr,Blatt,Platte,Draht usw. |

| Verpackung | Wasserdichtes Papier und Holzpaletten, Holzkiste |

| Ladehafen | Hafen von Shanghai |

| Preisbegriff | Exw, FOB, CIF, CFR |

| Lieferzeit | innerhalb von 12 Tagen |

Hastelloy C276 / Legierung 2.4819 Nickellegierung Rundbar / Scheibe / Kreis Warmgewalzt und geschmiedet

Hastelloy C276 (UNS N10276, W. Nr. 2.4819) ist eine hochwertige Nickel-Molybdän-Chrom-Legierung, die für ihre außergewöhnliche Korrosionsbeständigkeit in rauen Umgebungen bekannt ist.vor allem gegen oxidierende und reduzierende MedienDie warmgewalzten und geschmiedeten runden Stäbe, Scheiben und Kreise dieser Legierung nutzen optimierte Fertigungsprozesse, um die mechanische Festigkeit, die strukturelle Integrität und die Maßgenauigkeit zu verbessern.Sie sind ideal für kritische industrielle Anwendungen geeignet, bei denen Zuverlässigkeit und Haltbarkeit nicht verhandelbar sind..

1Chemische Zusammensetzung (Schlüsselparameter)

Die überlegene Leistungsfähigkeit von Hastelloy C276 beruht auf seiner präzise kontrollierten chemischen Zusammensetzung,mit einer Breite von mehr als 20 mm, jedoch nicht mehr als 30 mm,Nachstehend die typische Zusammensetzung nach internationalen Normen:

| Elemente | Inhaltbereich (%) | Funktion |

|---|---|---|

| Nickel (Ni) | 54.0 bis 60.0 | Grundmetall; bietet Duktilität, Zähigkeit und Beständigkeit gegen Spannungskorrosion |

| Chrom (Cr) | 14.5 bis 16.5 | Verbessert die Oxidationsbeständigkeit und die Resistenz gegen Schwefelsäure/Stickstoffsäure |

| Molybdän (Mo) | 15.0 bis 17.0 | Kritisch für die Beständigkeit gegen Reduktionsmedien (z. B. Salzsäure) und Pittingkorrosion |

| Wolfram (W) | 3.0 bis 4.5 | Ergänzt Molybdän, um die Beständigkeit gegen Spaltkorrosion und lokalisierte Angriffe zu erhöhen |

| Eisen (Fe) | ≤ 50 | Verbessert die Verarbeitbarkeit beim Warmwalzen/Schmieden, ohne die Korrosionsbeständigkeit zu beeinträchtigen |

| Kohlenstoff (C) | ≤ 0010 | Minimiert zur Verhinderung von Karbidniederschlag (vermeidet intergranulare Korrosion bei hohen Temperaturen) |

| Silizium (Si) | ≤ 008 | Kontrolle der Oxidbildung und Verbesserung der Gieß-/Schmiedequalität |

| Mangan (Mn) | ≤ 10 | Hilft bei der Entoxidation während der Herstellung; hält die Legierungsduktilität aufrecht |

| Fosfor (P) | ≤ 0040 | Zur Vermeidung der Bruchbarkeit und zur Verringerung der Korrosionsgefahren eingeschränkt |

| Schwefel (S) | ≤ 0030 | Minimiert, um beim Schmieden heißes Rissen zu verhindern und die Korrosionsbeständigkeit zu verbessern |

2Mechanische und physikalische Eigenschaften

Warmgewalzte und geschmiedete runde Stäbe aus Hastelloy C276 weisen im Vergleich zu gegossenen oder kaltbearbeiteten Varianten dank der Kornveredelung während der thermischen Verarbeitung verbesserte mechanische Eigenschaften auf.

2.1 Mechanische Eigenschaften (typische Werte für warmgewalzte/verfälschte Stäbe, in gegrilltem Zustand)

| Eigentum | Einheit | Wert (Gewärmt, 25°C/77°F) |

|---|---|---|

| Zugfestigkeit (UTS) | MPa | ≥ 790 |

| Ertragsstärke (0,2% Offset) | MPa | ≥ 380 |

| Ausdehnung (in 50 mm) | % | ≥ 40 |

| Härte (Brinell, HB) | - | ≤ 210 |

| Schlagfestigkeit (Charpy V-Notch) | J | ≥ 100 (bei 25°C) |

2.2 Physikalische Eigenschaften

| Eigentum | Einheit | Wert (bei 25°C/77°F, sofern nicht angegeben) |

|---|---|---|

| Dichte | G/cm3 | 8.89 |

| Schmelzbereich | °C | 1325 bis 1370 |

| Wärmeleitfähigkeit | W/m·K) | 11.8 (bei 100°C) |

| Koeffizient der thermischen Ausdehnung (CTE) | Bei der Prüfung der Einhaltung der Vorschriften für die Berechnung der Emissionswerte | 12.4 (20 - 100°C) |

| Elektrische Widerstandsfähigkeit | Ohm·mm2/m | 1.37 |

| Modul der Elastizität | GPa | 205 |

3Herstellungsprozess: Warmgewalzt oder geschmiedet

Die Warmwalz- und Schmiedeprozesse sind entscheidend für die Optimierung der Leistung von Hastelloy C276-Rundenstäben:

-

warmgewalzte Runde Stäbe:Hergestellt durch Erhitzen der Legierungsplatte auf 1150 - 1250 °C (über der Wiederkristallisierungstemperatur) und Walzen durch aufeinanderfolgende Stäube, um den gewünschten Durchmesser (typischerweise 6 mm - 300 mm) zu erreichenDas Verfahren verbessert die Duktilität, verfeinert die Kornstruktur und gewährleistet eine einheitliche Größengenauigkeit.

-

geschmiedete runde Stäbe/Schaltplatten/Kreise: Hergestellt durch hohe Druckbelastung erhitzter Schaltplatten (1100 - 1200 °C) mit Hilfe von Pressen oder Hammern, deren Form in runde Stäbe, Schaltplatten (Stärke: 10 mm - 500 mm) erfolgt;DurchmesserDas Schmieden beseitigt innere Defekte (z. B. Porosität), erhöht die mechanische Festigkeit (insbesondere die Stoßfestigkeit) und richtet den Kornfluss mit der Spannungsrichtung des Teils aus.Schmiedeprodukte werden vorzugsweise für Hochdruckprodukte verwendet, Hochtemperaturanwendungen (HPHT).

4. Internationale Normen und Spezifikationen

Hastelloy C276-Rundbalken, -scheiben und -kreise entsprechen weltweit anerkannten Normen zur Gewährleistung von Konsistenz und Qualität:

| Standardorganisation | Standardnummer | Anwendungsbereich |

|---|---|---|

| ASTM Internationale | ASTM B574 | Nickellegierte Stangen, Stangen und Drähte (Hauptnorm für warmgewalzte/geschmiedete Stangen) |

| ASTM Internationale | ASTM B622 | Platte, Blech und Streifen aus Nickellegierungen (Referenz für Scheiben/Kreise) |

| ASME | ASME SB574 | Kessel- und Druckbehältercode (für HPHT-Anwendungen) |

| DIN (Deutschland) | DIN EN 10095 | Hitzebeständige Stähle und Nickellegierungen (einschließlich 2.4819) |

| ISO-Nummern | ISO 9723 | Nickel und Nickellegierungen |

| JIS (Japan) | JIS H4551 | mit einer Breite von nicht mehr als 30 mm |

5. Gleichwertige Abschlüsse

Hastelloy C276 wird je nach regionalen Normen weltweit unter verschiedenen Bezeichnungen vermarktet.

| Regionales System | Bezeichnung der Klasse | Entsprechende Norm |

|---|---|---|

| UNS (USA) | N10276 | ASTM B574, ASME SB574 |

| W. Nr. (Deutschland) | 2.4819 | DIN EN 10095, DIN 17750 |

| BS (Vereinigtes Königreich) | NA 44 | BS 3074 (Teil 3) |

| JIS (Japan) | NW 276 | JIS H4551 |

| GOST (Russland) | Der Name des Herstellers: | GOST 9668 |

| EN (Europa) | NiCr21Mo14W | Einheitliche Prüfungen |

6. Hauptvorteile der Leistung

Hastelloy C276-Rundenbalken zeichnen sich durch ihre einzigartige Kombination von Eigenschaften aus, die sie vielen anderen Nickellegierungen überlegen machen:

- Außergewöhnliche Korrosionsbeständigkeit: Widerstand gegen oxidative (z. B. Stickstoffsäure, Meerwasser) und reduzierende (z. B. Salzsäure, Schwefelsäure) Medien.und Spannungskorrosionscracking (SCC) in chloridreichen Umgebungen.

- Hochtemperaturstabilität: Beibehält mechanische Festigkeit und Korrosionsbeständigkeit bis zu 1093 °C (2000 °F), so dass es für Anwendungen mit hoher Temperatur (z. B. Ofenkomponenten) geeignet ist.

- Ausgezeichnete Fertigbarkeit: Warmgewalzte und geschmiedete Varianten bieten eine gute Duktilität, so dass Biegen, Schweißen und Bearbeiten (mit Karbidwerkzeugen) möglich sind, um kundenspezifische Bauteilanforderungen zu erfüllen.

- Niedriges Kohlenstoffgehalt: Der niedrige Kohlenstoffgehalt minimiert die Bildung von Chromkarbiden während des Schweißens oder der Wärmebehandlung und beseitigt die Risiken einer intergranulären Korrosion.

7. Anwendungen

Hastelloy-C276-Rundbalken, -scheiben und -kreise werden in Industriezweigen, in denen Korrosionsbeständigkeit und Hochtemperaturleistung von entscheidender Bedeutung sind, weit verbreitet verwendet:

- Chemische Verarbeitung: Reaktoren, Wärmetauscher, Ventile und Pumpenwellen (für den Umgang mit Säuren, Lösungsmitteln und korrosiven Schlammen).

- Öl und Gas: Komponenten für die Bohrungen, Bohrkopfgeräte und Rohrleitungen (beständig gegen saures Gas, Sole und Chlorid-induzierte Korrosion).

- Pharmazeutische und Lebensmittelverarbeitung: Gefäße, Mischer und Sanitärgeräte (konform mit FDA-Standards; widerstandsfähig gegen Reinigungsmittel und Sterilisationsverfahren).

- Luftfahrt und Verteidigung: Verbrennungsräume von Düsenmotoren, Turbinenblätter und Raketenkomponenten (widersteht hoher Hitze und aggressiven Brennstoffen).

- Umwelttechnik: Systeme zur Entschwefelung von Rauchgasen, Abwasseraufbereitungsanlagen und Verbrennungsteile (widerstehen sauren Rauchgasen und giftigen Chemikalien).

- Stromerzeugung: Kesselrohre, Dampfturbinen und Kernkraftwerkskomponenten (handhabt hohen Druck, hohe Temperatur und Kältemittelkorrosion).

![]()

![]()

![]()

![]()

Empfohlene Produkte