Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

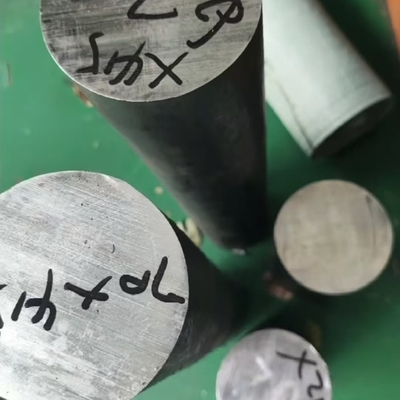

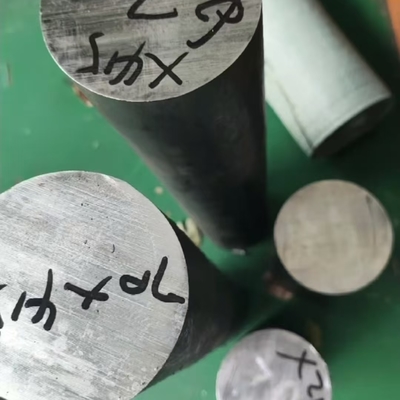

Hastelloy C276 / Κράμα 2.4819 Ράβδος Νικελίου Στρογγυλή / Δίσκος / Κύκλος Εξώθησης και Σφυρηλάτησης C276 Στρογγυλή Ράβδος

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | c276 |

| Ποσότητα παραγγελίας min | 500 κιλά |

| Τιμή | 40-45 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Λεπτομέρειες

| Προϊόντα | Πλάκα από κράμα νικελίου | Βαθμός | c276 |

|---|---|---|---|

| Διάμετρος | 6 - 350mm | Μήκος | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Πρότυπο | Astm en | Υπηρεσία | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | Μαύρο, φωτεινό. |

| Επισημαίνω | Hastelloy C276 round bar,Alloy 2.4819 forged rod,Nickel alloy hot rolled disc |

||

Περιγραφή προϊόντων

Χαστέλλοι C276 / κράμα 2.4819 Νικέλιο Σύνθεση Στρογγυλή ράβδος / δίσκος / κύκλος Ζεστά κυλούμενα και σφυρηλατημένα C276 Στρογγυλή ράβδο

Γρήγορες πληροφορίες

| Αξία | Χέιστελοϊ C276 / 2.4819 | Σχήμα | Στρογγυλή μπάρα |

| Διάμετρος | 6.0 - 350 mm | Τύπος | Ζεστά τυλιγμένα, σφυρηλατημένα |

| Διάρκεια | Προσαρμοσμένο Κόψιμο οποιουδήποτε μήκους κατά παραγγελία | Πιστοποιητικό | EN 10204-3.1 |

Περισσότερες πληροφορίες προδιαγραφών

| Ονομασία των προϊόντων | Χαστέλλοι C276 στρογγυλή ράβδο |

| Διάμετρος | 6.0 - 350 mm |

| Διάρκεια | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Επιφάνεια | Μαύρο, φωτεινό. |

| Ετικέτα | ΔΕΛΤΑ |

| Υπηρεσία | κοπή |

| Τροποποιημένο | 2 κιλά |

| Άλλος τύπος | Στρογγυλή ράβδο, ταινία, τροχιά, σωλήνα, φύλλο, πλάκα, σύρμα κλπ. |

| Συσκευή | υδατοασφαλές χαρτί και ξύλινες παλέτες, ξύλινο κουτί |

| Λιμένας φόρτωσης | Λιμάνι της Σαγκάης |

| Όρος τιμής | Επικαιροποιημένα προϊόντα |

| Χρόνος παράδοσης | εντός 12 ημερών |

Χαστέλλοι C276 / κράμα 2.4819 Νικέλιο Σύνθεση Στρογγυλή ράβδος / δίσκος / κύκλος Ζεστά κυλούμενα και σφυρηλατημένα C276 Στρογγυλή ράβδο

Το Hastelloy C276 (UNS N10276, W. Nr. 2.4819) είναι ένα υψηλής ποιότητας κράμα νικελίου-μολυβδενίου-χρωμίου γνωστό για την εξαιρετική αντοχή του στη διάβρωση σε σκληρά περιβάλλοντα,ειδικότερα ενάντια σε οξειδωτικά και μειωτικά μέσαΟι ζεστές τυλιγμένες και σφυρηλατημένες στρογγυλές ράβδοι, δίσκοι και κύκλοι αυτού του κράματος αξιοποιούν βελτιστοποιημένες διαδικασίες κατασκευής για την ενίσχυση της μηχανικής αντοχής, της δομικής ακεραιότητας και της διαμετρικής ακρίβειας,καθιστώντας τους ιδανικούς για κρίσιμες βιομηχανικές εφαρμογές όπου η αξιοπιστία και η αντοχή δεν είναι διαπραγματεύσιμες.

1Χημική σύνθεση (κλειδιώδεις παράμετροι)

Η ανώτερη απόδοση του Hastelloy C276 προέρχεται από την ακριβώς ελεγχόμενη χημική του σύνθεση,που εξισορροπεί το νικέλιο (το βασικό στοιχείο) με στοιχεία κράματος για την αντίσταση στη διάβρωση και τη διατήρηση της μηχανικής σταθερότηταςΠαρακάτω παρουσιάζεται η τυπική σύνθεση σύμφωνα με τα διεθνή πρότυπα:

| Στοιχείο | Περιοχή περιεχομένου (%) | Λειτουργία |

|---|---|---|

| Νικέλιο (Ni) | 54.0 - 60.0 | Βασικό μέταλλο: παρέχει ευελιξία, αντοχή και αντοχή στην διάσπαση από διάβρωση |

| Χρώμιο (Cr) | 14.5 - 16.5 | Βελτιώνει την αντοχή στην οξείδωση και την αντοχή στο θειικό/αζωτικό οξύ |

| Μολυβδένιο (Mo) | 15.0 - 17.0 | Κρίσιμη για την αντοχή σε περιοριστικά μέσα (π.χ. υδροχλωρικό οξύ) και διαβρωτική διάβρωση |

| Τούλφραμ (W) | 3.0 - 4.5 | Συμπληρώνει το μολυβδένιο για να ενισχύσει την αντοχή στη διάσπαση διάβρωσης και την τοπική επίθεση |

| Σίδηρος (Fe) | ≤ 5.0 | Βελτιώνει την επεξεργασιμότητα κατά τη διάρκεια της θερμής έλασης/σφυρηλάτησης χωρίς να θέτει σε κίνδυνο την αντοχή στη διάβρωση |

| Άνθρακας (C) | ≤ 0.010 | Ελαχιστοποιείται για την πρόληψη της βροχόπτωσης καρβιδίων (αποφεύγει τη διασωματική διάβρωση σε υψηλές θερμοκρασίες) |

| Σιλικόνη (Si) | ≤ 0.08 | Ελέγχει το σχηματισμό οξειδίων και βελτιώνει την ποιότητα της χύτευσης/σφυρηλασίας |

| Μαγγάνιο (Mn) | ≤ 1.0 | Βοηθά στην αποοξείδωση κατά την παρασκευή· διατηρεί την ευελιξία του κράματος |

| Φωσφόρος (P) | ≤ 0.040 | Περιορισμένα για την αποφυγή της εύθραυστης διάστασης και τη μείωση των κινδύνων διάβρωσης |

| Θείο (S) | ≤ 0.030 | Ελαχιστοποιείται για την πρόληψη της καυτής ρωγμάτωσης κατά τη σφυρηλάτηση και τη βελτίωση της αντοχής στη διάβρωση |

2Μηχανικές και φυσικές ιδιότητες

Οι στρογγυλές ράβδοι Hastelloy C276 θερμής έλασης και σφυρηλάτησης παρουσιάζουν βελτιωμένες μηχανικές ιδιότητες σε σύγκριση με τις εκχυλισμένες ή ψυχρά επεξεργασμένες παραλλαγές, χάρη στην επεξεργασία των κόκκων κατά τη θερμική επεξεργασία.

2.1 Μηχανολογικές ιδιότητες (τυπικές τιμές για θερμά κυλούμενα/φυλακτισμένα σχοινιά, σε κατάσταση αναψύκλωσης)

| Ιδιοκτησία | Μονάδα | Αξία (Επιθεωρημένη, 25°C/77°F) |

|---|---|---|

| Δυνατότητα τράβηξης (UTS) | MPa | ≥ 790 |

| Δυνατότητα απόδοσης (0,2% αντιστάθμιση) | MPa | ≥ 380 |

| Επεκτάσεις (σε 50 mm) | % | ≥ 40 |

| Σκληρότητα (Brinell, HB) | - | ≤ 210 |

| Δυνατότητα πρόσκρουσης (Charpy V-Notch) | J | ≥ 100 (σε 25°C) |

2.2 Φυσικές ιδιότητες

| Ιδιοκτησία | Μονάδα | Αξία (σε θερμοκρασία 25°C/77°F, εκτός εάν αναφέρεται) |

|---|---|---|

| Σφιχτότητα | g/cm3 | 8.89 |

| Πεδίο τήξης | °C | 1325 - 1370 |

| Θερμική αγωγιμότητα | W/(m·K) | 11.8 (σε θερμοκρασία 100 °C) |

| Συντελεστής θερμικής διαστολής (CTE) | μm/m·K | 12.4 (20 - 100°C) |

| Ηλεκτρική αντίσταση | Ω·mm2/m | 1.37 |

| Μοντέλο ελαστικότητας | ΓΠΑ | 205 |

3. Διαδικασία κατασκευής: Ζεστή έλαση έναντι σφυρηλατήματος

Οι διαδικασίες θερμής έλασης και σφυρηλάτησης είναι κρίσιμες για τη βελτιστοποίηση των επιδόσεων των στρογγυλών ράβδων Hastelloy C276:

-

Στρογγυλοί ράβδοι θερμής έλασης:Παρασκευάζεται με θέρμανση του σκελετού από κράμα σε 1150 - 1250 °C (πάνω από τη θερμοκρασία ανακρυσταλλώσεώς του) και κυλίνδρωσή του μέσω διαδοχικών σχηματισμών για να επιτευχθεί η επιθυμητή διάμετρος (συνήθως 6 mm - 300 mm)Η διαδικασία αυτή βελτιώνει την ευελιξία, βελτιώνει τη δομή των κόκκων και εξασφαλίζει ομοιόμορφη διαμετρική ακρίβεια.

-

Σφυρηλατημένες στρογγυλές ράβδοι/διάσκοποι/κύκλοι: Κατασκευάζονται με την εφαρμογή υψηλής πίεσης σε θερμαινόμενες ράβδοι (1100 - 1200°C) με πιέσεις ή σφυριά, με τη διαμόρφωση τους σε στρογγυλές ράβδους, δίσκους (πλάτος: 10 mm - 500 mm)διάμετροςΗ σφυρηλασία εξαλείφει τα εσωτερικά ελαττώματα (π.χ. πορώδεςτητα), ενισχύει τη μηχανική αντοχή (ειδικά την αντοχή από την πρόσκρουση) και ευθυγραμμίζει τη ροή των κόκκων με την κατεύθυνση έντασης του τμήματος.Τα πλαστά προϊόντα προτιμούνται για υψηλής πίεσης, εφαρμογές υψηλής θερμοκρασίας (HPHT).

4Διεθνή πρότυπα και προδιαγραφές

Οι στρογγυλές ράβδοι, οι δίσκοι και οι κύκλοι Hastelloy C276 συμμορφώνονται με παγκοσμίως αναγνωρισμένα πρότυπα για τη διασφάλιση της συνέπειας και της ποιότητας:

| Τυποποιημένη οργάνωση | Τυπικός αριθμός | Πεδίο εφαρμογής |

|---|---|---|

| Διεθνές ASTM | ΑΣTM B574 | Στραβή, ράβδος και σύρμα από κράμα νικελίου (πρωταρχικό πρότυπο για ζεσταθείσες/σφυρηλατημένες ράβδους) |

| Διεθνές ASTM | ΑΣTM Β622 | Πλάκα, φύλλο και ταινία από κράμα νικελίου (αναφορά για δίσκους/κύκλους) |

| ASME | Ειδικότερα, | Κωδικός λέβητα και δοχείου υπό πίεση (για εφαρμογές HPHT) |

| DIN (Γερμανία) | DIN EN 10095 | Χάλυβες ανθεκτικές στη θερμότητα και κράματα νικελίου (συμπεριλαμβανομένων των 2.4819) |

| ISO | ISO 9723 | Νικέλιο και κράματα νικελίου ∆άγκοι και ράβδοι |

| ΔΕΣ (Ιαπωνία) | JIS H4551 | Νικέλιο και ράβδοι από κράμα νικελίου |

5. Εξισοδύναμες βαθμίδες

Το Hastelloy C276 διατίθεται στο εμπόριο με διαφορετικές ονομασίες παγκοσμίως, ανάλογα με τα περιφερειακά πρότυπα.

| Περιφερειακό σύστημα | Ονομασία βαθμού | Αντίστοιχο πρότυπο |

|---|---|---|

| Εθνικές Υπηρεσίες (ΗΠΑ) | N10276 | ΑΣTM B574, ASME SB574 |

| W. Nr. (Γερμανία) | 2.4819 | DIN EN 10095, DIN 17750 |

| BS (Ηνωμένο Βασίλειο) | NA 44 | BS 3074 (Μέρος 3) |

| ΔΕΣ (Ιαπωνία) | NW 276 | JIS H4551 |

| GOST (Ρωσία) | KhN68MVTYu | ΓΕΣΤ 9668 |

| EN (Ευρώπη) | NiCr21Mo14W | EN 10095 |

6Βασικά πλεονεκτήματα απόδοσης

Οι στρογγυλές ράβδοι Hastelloy C276 ξεχωρίζουν για τον μοναδικό συνδυασμό των ιδιοτήτων τους, καθιστώντας τους ανώτερους από πολλά άλλα κράματα νικελίου:

- Εξαιρετική αντοχή στη διάβρωση: Αντιστέκεται τόσο στα οξειδωτικά (π.χ. νιτρικό οξύ, θαλασσινό νερό) όσο και στα ελαττωτικά (π.χ. υδροχλωρικό οξύ, θειικό οξύ).και διάσπαση διά διά διάταξης (SCC) σε περιβάλλοντα πλούσια σε χλωρίδια.

- Σταθερότητα σε υψηλές θερμοκρασίες: Διατηρεί μηχανική αντοχή και αντοχή στη διάβρωση έως 1093 °C (2000 °F), καθιστώντας το κατάλληλο για εφαρμογές υψηλής θερμοκρασίας (π.χ. εξαρτήματα φούρνου).

- Εξαιρετική κατασκευαστική ικανότητα: Οι παραλλαγές θερμής έλασης και σφυρηλάτησης προσφέρουν καλή ευελιξία, επιτρέποντας την κάμψη, την συγκόλληση και τη μηχανική (με εργαλεία καρβιδίου) για την ικανοποίηση των απαιτήσεων εξαρτήματος.

- Χαμηλή βροχόπτωση καρβιδίων: Η χαμηλή περιεκτικότητα σε άνθρακα ελαχιστοποιεί το σχηματισμό καρβιδίων χρωμίου κατά τη συγκόλληση ή τη θερμική επεξεργασία, εξαλείφοντας τους κινδύνους διασωματικής διάβρωσης.

7Εφαρμογές

Οι στρογγυλές ράβδοι, οι δίσκοι και οι κύκλοι του Hastelloy C276 χρησιμοποιούνται ευρέως σε βιομηχανίες όπου η αντοχή στη διάβρωση και οι επιδόσεις σε υψηλές θερμοκρασίες είναι κρίσιμες:

- Χημική επεξεργασία: αντιδραστήρες, ανταλλακτές θερμότητας, βαλβίδες και άξονες αντλιών (για χειρισμό οξέων, διαλυτών και διαβρωτικών λιπασμάτων).

- Πετρέλαιο και φυσικό αέριο: Συσκευάσματα κάτω από το λάκκο, εξοπλισμός κεφαλαίου πηγάδι και συστήματα αγωγών (αντιστέκονται σε ξινό αέριο, αλμυρές ύλες και διάβρωση που προκαλείται από χλωρίδιο).

- Φαρμακευτική & Επεξεργασία Τροφίμων: Συσκευές, αναμεικτικά και υγιεινά εξαρτήματα (συμμορφώνεται με τα πρότυπα του FDA, αντιστέκεται στους καθαριστικούς παράγοντες και τις διαδικασίες αποστείρωσης).

- Αεροδιαστημική και Άμυνα: Θάλαμοι καύσης των κινητήρων αεριωθούμενων, λεπίδες τουρμπίνων και εξαρτήματα πυραύλων (αντιστέκει σε υψηλή θερμότητα και επιθετικά καύσιμα).

- Περιβαλλοντική Μηχανική: Συστήματα αποσάλφιωσης καπνιστικών αερίων (FGD), εξοπλισμός επεξεργασίας λυμάτων και εξαρτήματα αποτεφρωτηρίων (αντιστέκονται σε όξινα καπνιστικά αέρια και τοξικές χημικές ουσίες).

- Ηλεκτρική παραγωγή: σωλήνες λέβητα, ατμογεννήτριες και συστατικά πυρηνικών εγκαταστάσεων (διαχειρίζεται υψηλή πίεση, υψηλή θερμοκρασία και διάβρωση ψυκτικού).

![]()

![]()

![]()

![]()

Συνιστώμενα προϊόντα