All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

321 Stainless Steel Strip Cold Rolled 0.4-3.0mm 2B Surface

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Strip | Thickness | 0.4 - 3.0mm |

|---|---|---|---|

| Width | Within 1219mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | 321 stainless steel strip 0.4-3.0mm,cold rolled stainless steel strip 2B surface,321 stainless steel strip with warranty |

||

Product Description

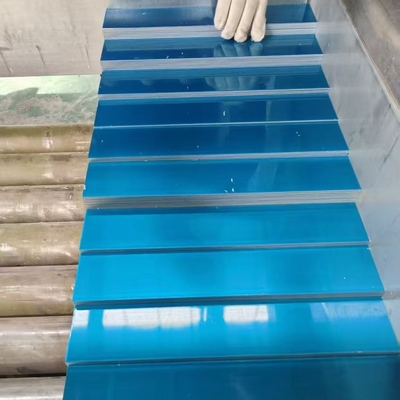

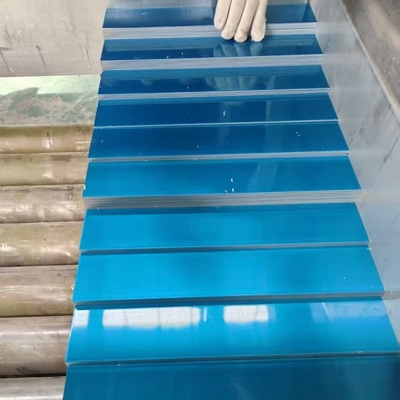

321 Stainless Steel Strip Cold Rolled TISCO POSCO Stainless Steel Coils 2B surface With High Temperature Resistant

Product Attributes

| Attribute | Value |

| Products | 321 stainless steel strip |

| Thickness | 0.4-3.0mm |

| Width | within 1219mm |

| MOQ | 500 kgs |

| Other | 201 301 304 304L 309S 310S 316L 316Ti 410 420 430 436 439 441 444 440A/B/C,2205,2507,904L,C276,400,600,625,926,825.etc |

| Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS |

| Packing | wooden frame and water proof paper |

Overview

321 stainless steel strips, offered by leading manufacturers like TISCO (Taiyuan Iron and Steel Co., Ltd.) and POSCO, are premium austenitic stainless steels stabilized with titanium. Renowned for exceptional high-temperature resistance, oxidation stability, and excellent weldability, these cold-rolled strips with a 2B surface finish are engineered for demanding industrial applications where heat and corrosion resistance are critical.

Key Parameters

- Material Grade: 321 (a titanium-stabilized austenitic stainless steel, designed to prevent carbide precipitation during high-temperature exposure or welding).

- Chemical Composition (Typical, %):

- Chromium (Cr): 17.0 - 19.0 (enhances oxidation and corrosion resistance).

- Nickel (Ni): 9.0 - 12.0 (stabilizes the austenitic structure, improving ductility and toughness).

- Titanium (Ti): 5×(C + N) - 0.70 (stabilizes carbides, preventing intergranular corrosion).

- Carbon (C): ≤ 0.08 (low carbon content reduces carbide formation).

- Manganese (Mn): ≤ 2.0.

- Silicon (Si): ≤ 1.0.

- Phosphorus (P): ≤ 0.045.

- Sulfur (S): ≤ 0.030.

- Mechanical Properties:

- Tensile Strength: ≥ 520 MPa.

- Yield Strength: ≥ 205 MPa.

- Elongation: ≥ 40% (in 50mm gauge length).

- High-Temperature Resistance: Maintains structural integrity and oxidation resistance at continuous service temperatures up to 870°C, making it suitable for high-heat environments.

Standards

321 stainless steel strips adhere to stringent international standards, ensuring consistent quality and performance:

- ASTM A240/A240M (Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and General Applications).

- JIS G4305 (Stainless Steel Sheets and Strips).

- EN 10088-2 (Stainless Steels - Part 2: Technical Delivery Conditions for Sheets, Plates, and Strips).

- GB/T 3280 (Chinese National Standard for Stainless Steel Cold-Rolled Sheets and Strips, applicable to TISCO products).

Specifications

- Processing: Cold-rolled (ensures precise thickness control, smooth surface finish, and improved dimensional accuracy).

- Thickness: Typically available in a range of 0.1mm - 3.0mm (customizable to meet specific industrial requirements).

- Width: Common ranges from 100mm to 1250mm (adjustable based on customer needs for seamless integration into manufacturing processes).

- Surface Finish: 2B (cold-rolled, annealed, and pickled, resulting in a smooth, matte finish with excellent flatness—ideal for applications requiring paintability or further processing).

- Form: Supplied in coils for efficient handling and automated production lines.

Similar Grades

321 stainless steel is part of the stabilized austenitic family, with several 相近牌号 (similar grades) offering comparable high-temperature and corrosion resistance:

- 347: Stabilized with niobium (Nb) instead of titanium, providing similar high-temperature performance and weldability, often used as an alternative in applications with strict welding requirements.

- 316Ti: A molybdenum-containing variant (16-18% Cr, 10-14% Ni, 2-3% Mo) with titanium stabilization, offering enhanced corrosion resistance in chloride environments alongside high-temperature strength.

- 1.4541 (EN designation): European equivalent to 321, with matching chemical composition and mechanical properties.

- 321H: A higher-carbon version (C: 0.04-0.10%) designed for improved high-temperature strength in extreme heat applications.

Applications

Thanks to its superior high-temperature resistance, oxidation stability, and weldability, 321 stainless steel strips are widely used in:

- Aerospace and Aviation: Components like exhaust systems, jet engine parts, and heat shields, where exposure to extreme temperatures and corrosive gases is common.

- Petrochemical Industry: Heat exchangers, furnace parts, and piping systems handling high-temperature fluids or corrosive media.

- Automotive: Turbocharger components, exhaust manifolds, and emission control systems requiring heat and corrosion resistance.

- Power Generation: Boiler tubes, turbine parts, and incinerator components exposed to high heat and aggressive environments.

- Food Processing: High-temperature equipment (e.g., sterilizers) due to its non-toxic properties and resistance to oxidation.

![]()

![]()

![]()

![]()

![]()

Recommended Products