모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

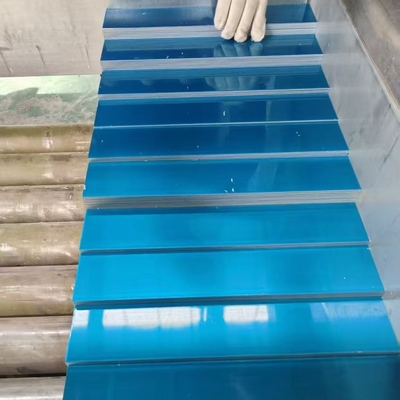

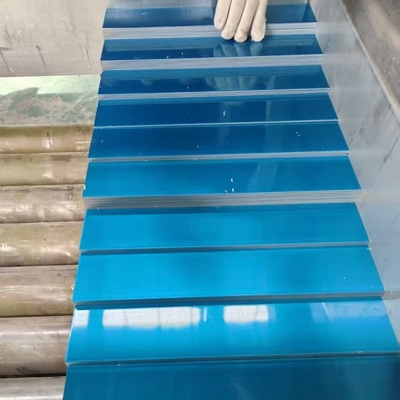

321 스테인리스강 스트립 냉간 압연 0.4-3.0mm 2B 표면

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x제품 상세 정보

| 제품 | 스테인레스 스틸 스트립 | 두께 | 0.4-3.0mm |

|---|---|---|---|

| 너비 | 1219mm 이내 | 모크 | 500kgs |

| 등급 | 200 시리즈 300 시리즈 300 시리즈 | 표면 | BA 2B No.4 HL 8K No.1 |

| 기준 | astm en gb jis | 포장 | 나무 프레임 및 방수 용지 |

| 강조하다 | 321 스테인리스강 스트립 0.4-3.0mm,냉간 압연 스테인리스강 스트립 2B 표면,보증이 있는 321 스테인리스강 스트립 |

||

제품 설명

321 스테인레스 스틸 스트립 콜드 롤 롤 Tisco Posco 스테인레스 스틸 코일 2b 고온 저항성이있는 표면

제품 속성

| 기인하다 | 값 |

| 제품 | 321 스테인레스 스틸 스트립 |

| 두께 | 0.4-3.0mm |

| 너비 | 1219mm 이내 |

| 모크 | 500kgs |

| 다른 | 201 301 304 304L 309S 310S 316L 316TI 410 420 430 436 439 441 444 440A/B/C, 2205,2507,904L, C276,400,600,625,926,825.etc |

| 표면 | BA 2B No.4 HL 8K No.1 |

| 기준 | astm en gb jis |

| 포장 | 나무 프레임 및 방수 용지 |

개요

Tisco (Taiyuan Iron and Steel Co., Ltd.) 및 Posco와 같은 주요 제조업체가 제공하는 321 스테인레스 스틸 스트립은 티타늄으로 안정화 된 프리미엄 오스테 나이트 스테인리스 강입니다. 탁월한 고온 저항성, 산화 안정성 및 탁월한 용접 성으로 유명한 2B 표면 마감 처리 된이 냉간 압연 스트립은 열 및 부식성이 중요한 산업 응용 분야를 요구합니다.

주요 매개 변수

- 재료 등급 : 321 (고온 노출 또는 용접 중에 탄화물 침전을 방지하도록 설계된 티타늄 안정 오스테 나이트 스테인리스 스틸).

- 화학 조성 (전형적인, %) :

- 크롬 (CR) : 17.0-19.0 (산화 및 내식성 향상).

- 니켈 (NI) : 9.0-12.0 (오스테 나이트 구조를 안정화시켜 연성 및 강인성을 향상시킵니다).

- 티타늄 (TI) : 5 × (C + N) -.0.70 (탄화물을 안정화시켜 편 부식 방지).

- 탄소 (C) : ≤ 0.08 (저탄소 함량은 탄화물 형성을 감소시킨다).

- 망간 (MN) : ≤ 2.0.

- 실리콘 (SI) : ≤ 1.0.

- 인 (P) : ≤ 0.045.

- 황 (들) : ≤ 0.030.

- 기계적 특성 :

- 인장 강도 : ≥ 520 MPa.

- 항복 강도 : ≥ 205 MPa.

- 신장 : ≥ 40% (50mm 게이지 길이).

- 고온 저항성 : 최대 870 ° C의 연속 서비스 온도에서 구조적 무결성 및 산화 저항을 유지하여 고열 환경에 적합합니다.

표준

321 스테인레스 스틸 스트립은 엄격한 국제 표준을 준수하여 일관된 품질과 성능을 보장합니다.

- ASTM A240/A240M (크롬 및 크롬-니켈 스테인레스 스틸 플레이트, 시트 및 압력 용기 및 일반 응용 분야의 표준 사양).

- JIS G4305 (스테인레스 스틸 시트 및 스트립).

- EN 10088-2 (스테인리스 강 - 파트 2 : 시트, 플레이트 및 스트립의 기술 전달 조건).

- GB/T 3280 (Tisco 제품에 적용 가능한 스테인레스 스틸 냉장 시트 및 스트립에 대한 중국 국가 표준).

명세서

- 처리 : 콜드 롤링 (정확한 두께 제어, 부드러운 표면 마감 및 개선 된 치수 정확도를 보장합니다).

- 두께 : 일반적으로 0.1mm -3.0mm의 범위 (특정 산업 요구 사항을 충족하기 위해 사용자 정의 가능)로 제공됩니다.

- 폭 : 100mm ~ 1250mm (제조 공정에 원활한 통합을위한 고객 요구에 따라 조정 가능).

- 표면 마감 : 2B (콜드 롤링, 어닐링 및 절인 절정으로 탁월한 평탄도가 부드럽고 매끄럽고 무광택 마감 처리됩니다.

- 형태 : 효율적인 처리 및 자동화 된 생산 라인을 위해 코일로 제공됩니다.

비슷한 성적

321 스테인레스 스틸은 안정화 된 오스테 나이트 패밀리의 일부이며, 비슷한 고온 및 부식 저항을 제공하는 여러 相近牌号 (유사한 등급) :

- 347 : 티타늄 대신 Niobium (NB)으로 안정화되어 유사한 고온 성능 및 용접 성을 제공하며, 종종 엄격한 용접 요구 사항이있는 응용 분야에서 대안으로 사용됩니다.

- 316TI : 티타늄 안정화를 통한 몰리브덴 함유 변형 (16-18% CR, 10-14% NI, 2-3% MO)으로 고온 강도와 함께 염화물 환경에서 강화 된 부식성을 제공합니다.

- 1.4541 (EN 지정) : 화학 조성 및 기계적 특성이 일치하는 유럽 321에 해당합니다.

- 321H : 극한 열 응용 분야에서 고온 강도를 향상시키기 위해 설계된 고 탄소 버전 (C : 0.04-0.10%).

응용 프로그램

우수한 고온 저항, 산화 안정성 및 용접 성 덕분에 321 스테인레스 스틸 스트립은 다음과 같이 널리 사용됩니다.

- 항공 우주 및 항공 : 배기 시스템, 제트 엔진 부품 및 열 방패와 같은 구성 요소는 극도의 온도 및 부식성 가스에 노출되는 것이 일반적입니다.

- 석유 화학 산업 : 열교환 기, 용광로 부품 및 고온 유체 또는 부식성 매체를 처리하는 배관 시스템.

- 자동차 : 터보 차저 부품, 배기 매니 폴드 및 열 및 부식 저항이 필요한 배출 제어 시스템.

- 발전 : 고열 및 공격적인 환경에 노출 된 보일러 튜브, 터빈 부품 및 소각로 구성 요소.

- 식품 가공 : 비 독성 특성 및 산화에 대한 저항으로 인한 고온 장비 (예 : 멸균기).

![]()

![]()

![]()

![]()

![]()

추천된 제품