-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

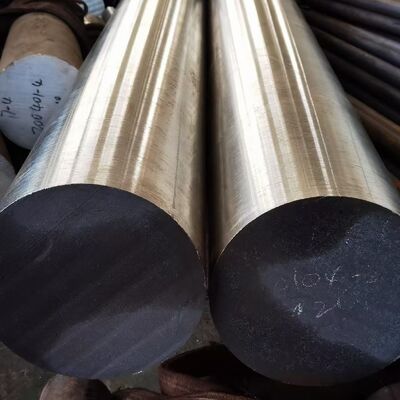

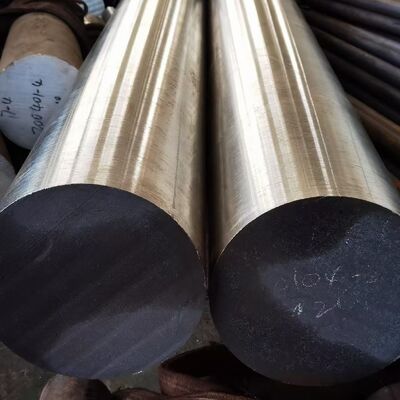

Precision Ground 1.4418 Stainless Steel Round Bars Low Carbon, Mo-Ni Alloyed for Excellent Weldability & Corrosion Resistance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products Name | 1.4418 Stainless Steel Bar | Diameter | 10 - 350mm |

|---|---|---|---|

| Length | 6m Or Cutting Any Length As Request | Surface | Black Or Polishing |

| Service | Cutting | Standard | ASTM DIN GB EN |

| Other Products | Round Bar, Square Bar, Flat Bar.etc | Technique | Hot Rolled |

Precision Ground 1.4418 Stainless Steel Round Bars Low Carbon, Mo-Ni Alloyed for Excellent Weldability & Corrosion Resistance

Products Specification

| Products Name | 1.4418 Stainless Steel Round Bar |

| Grade |

303,303Cu,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800,800H,825,926.etc |

| Products Diameter Range | φ3mm - φ350mm |

| Length | 6m/pcs or cutting any length as request |

| Surface | Pickling finishing, bright finishing |

| Standard | ASTM JIS,GB,DIN EN |

| Service | Cutting |

| Other Shape | Square , Flat, Hexagonal, Round.etc |

| Loading Port | Shanghai Port |

| MOQ | 50 kgs |

Overview

Key Features & Benefits

- High Strength-to-Weight Ratio: Ultimate tensile strength up to 1100 MPa after aging.

- Outstanding Corrosion Resistance: PREN ≥ 35; resists pitting, crevice corrosion, and chloride stress corrosion cracking—superior to 316L and 17-4PH.

- Excellent Low-Temperature Toughness: Maintains ductility and impact resistance down to –60°C (Charpy V-notch ≥ 50 J at –40°C).

- Superior Weldability: Can be welded using GTAW, GMAW, or laser methods with minimal risk of cracking; post-weld heat treatment optional but recommended for critical applications.

- Dimensional Stability: Precision grinding ensures straightness < 0.1 mm/m and concentricity within tolerance, reducing assembly time and scrap rates.

- Machinability: Better than austenitic grades due to its martensitic structure in the solution-annealed condition.

Typical Chemical Composition (Weight %)

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|---|

| Max/Min | ≤0.06 | ≤0.70 | ≤1.50 | ≤0.040 | ≤0.015 | 15.0–17.0 | 4.0–6.0 | 0.8–1.5 | ≤0.02 |

Mechanical Properties (After Standard Heat Treatment)

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Impact Toughness (–40°C, J) |

|---|---|---|---|---|---|

| Solution Annealed | 750–900 | 550–700 | 15–25 | 220–280 | ≥60 |

| Aged (550°C × 4h) | 900–1100 | 700–900 | 12–18 | 280–350 | ≥50 |

- Solution Annealing: 1020–1050°C × 30 min, followed by oil or air cooling.

- Aging (Precipitation Hardening): 480–550°C × 2–4 h, air cooled.

This dual-step process develops a fine dispersion of ε-Cu and Ni₃Ti precipitates, delivering peak strength without compromising toughness.

Physical Properties

| Property | Value |

|---|---|

| Density (20°C) | 7.8 g/cm³ |

| Melting Range | 1420–1460°C |

| Thermal Conductivity (100°C) | 15 W/(m·K) |

| Specific Heat (20°C) | 500 J/(kg·K) |

| Electrical Resistivity | 0.85 µΩ·m |

| Coefficient of Thermal Expansion (20–100°C) | 11.5 × 10⁻⁶ /K |

Applications

- Marine Engineering: Propeller shafts, rudder stocks, seawater pump components, offshore platform connectors.

- Oil & Gas: Downhole tools, high-pressure valves, subsea manifolds, sour service equipment (H₂S environments).

- Aerospace: Landing gear parts, turbine blades, fasteners requiring high fatigue resistance.

- Energy: Hydro turbine runners, nuclear reactor internals, steam generator tubes.

- Precision Machinery: High-strength spindles, molds, measuring instruments, and wear-resistant shafts.

Machining & Fabrication Guidelines

| Process | Recommended Parameters | Tooling Suggestions |

|---|---|---|

| Turning | Speed: 60–90 m/min; Feed: 0.1–0.2 mm/rev | Coated carbide inserts |

| Milling | Speed: 50–80 m/min; Feed: 0.05–0.15 mm/tooth | Ceramic or PVD-coated tools |

| Drilling | Speed: 15–25 m/min; Feed: 0.05–0.1 mm/rev | Cobalt HSS or solid carbide |

| Grinding | Wheel speed: 20–30 m/s | CBN or aluminum oxide wheels |

Welding Recommendations

- Preferred Method: GTAW (TIG) with ER2209 filler wire and Ar + 2% O₂ shielding gas.

- Interpass Temperature: Keep ≤150°C to avoid sensitization.

- Heat Input: Maintain between 5–15 kJ/cm.

- Post-Weld Treatment: Full solution annealing (1050°C × 30 min, water quench) is advised for critical corrosion service. Alternatively, localized stress relief at 850°C can reduce residual stresses.

Comparison with Common Stainless Grades

| Property | 1.4418 | 1.4462 (2205) | 316L | 17-4PH |

|---|---|---|---|---|

| Tensile Strength (MPa) | 900–1100 | 620–800 | 485 | 1310 |

| Yield Strength (MPa) | 700–900 | 450–550 | 170 | 1170 |

| Elongation (%) | 12–18 | 25 | 40 | 10 |

| PREN | ≥35 | ≥35 | ~25 | ~18.5 |

| Weldability | Excellent | Excellent | Excellent | Moderate |

| Cost Efficiency | High (vs. duplex) | Medium | Low | High |

Quality Assurance & Certifications

- EN 10272 (stainless steel bars for pressure purposes)

- ASTM A743/A744 (cast equivalents: CA6NM)

- NORSOK M-001 (for offshore applications)

- PED 2014/68/EU (Pressure Equipment Directive)

Available Sizes & Finishes

- Diameters: 10 mm to 300 mm (standard); custom sizes available.

- Lengths: 2000–6000 mm (cut-to-length upon request).

- Surface Finish: Precision ground (h9 tolerance), polished (optional Ra 0.4 µm).

- Packaging: VCI paper + wooden crates for export; moisture-controlled storage.

Why Choose Our 1.4418 Round Bars?

- Consistent Quality: Melted via EAF + AOD for ultra-low impurities (S < 0.015%).

- Traceability: Full heat number tracking from ingot to finished bar.

- Global Supply: Ready stock in Europe, Asia, and North America.

- Technical Support: Metallurgical consultation for heat treatment, welding, and design optimization.