-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

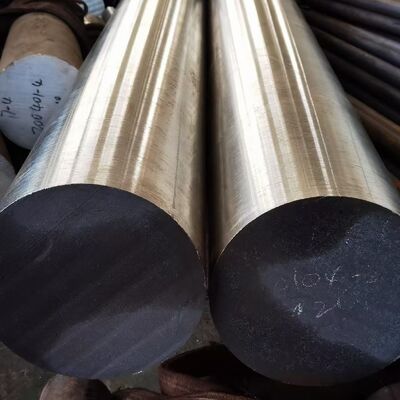

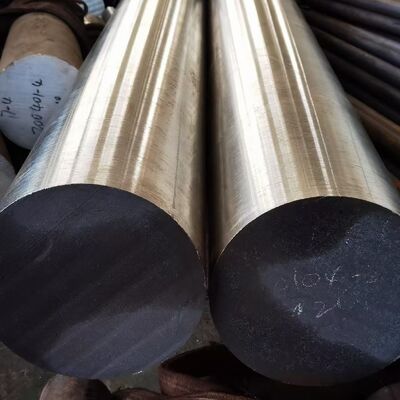

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Precision Ground 1.4418 Stainless Steel Round Bars Low Carbon, Mo-Ni Alloyed for Excellent Weldability & Corrosion Resistance

| Luogo di origine | Cina |

|---|---|

| Marca | Delta |

| Certificazione | ISO 9001 |

| Numero di modello | 1.4418 |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 3.5 - 5.5 USD/Kg |

| Imballaggi particolari | scatola di legno o rivestimento in carta impermeabile |

| Tempi di consegna | 5 - 10 giorni |

| Termini di pagamento | T/T, Western Union |

| Capacità di alimentazione | 50 tonnellate al mese |

Contattimi gratis campioni e buoni.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se avete di preoccupazione, forniamo la guida in linea di 24 ore.

x| Nome dei prodotti | 1.4418 barre in acciaio inossidabile | Diametro | 10 - 350mm |

|---|---|---|---|

| Lunghezza | 6m o tagliare qualsiasi lunghezza come richiesta | Superficie | nero o lucidato |

| Servizio | Taglio | Standard | ASTM Din GB en |

| Altri prodotti | barra rotonda, barra quadrata, barra piatta.etc | Tecnica | Laminato a caldo |

Precision Ground 1.4418 Stainless Steel Round Bars Low Carbon, Mo-Ni Alloyed for Excellent Weldability & Corrosion Resistance

Products Specification

| Products Name | 1.4418 Stainless Steel Round Bar |

| Grade |

303,303Cu,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800,800H,825,926.etc |

| Products Diameter Range | φ3mm - φ350mm |

| Length | 6m/pcs or cutting any length as request |

| Surface | Pickling finishing, bright finishing |

| Standard | ASTM JIS,GB,DIN EN |

| Service | Cutting |

| Other Shape | Square , Flat, Hexagonal, Round.etc |

| Loading Port | Shanghai Port |

| MOQ | 50 kgs |

Overview

Key Features & Benefits

- High Strength-to-Weight Ratio: Ultimate tensile strength up to 1100 MPa after aging.

- Outstanding Corrosion Resistance: PREN ≥ 35; resists pitting, crevice corrosion, and chloride stress corrosion cracking—superior to 316L and 17-4PH.

- Excellent Low-Temperature Toughness: Maintains ductility and impact resistance down to –60°C (Charpy V-notch ≥ 50 J at –40°C).

- Superior Weldability: Can be welded using GTAW, GMAW, or laser methods with minimal risk of cracking; post-weld heat treatment optional but recommended for critical applications.

- Dimensional Stability: Precision grinding ensures straightness < 0.1 mm/m and concentricity within tolerance, reducing assembly time and scrap rates.

- Machinability: Better than austenitic grades due to its martensitic structure in the solution-annealed condition.

Typical Chemical Composition (Weight %)

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|---|

| Max/Min | ≤0.06 | ≤0.70 | ≤1.50 | ≤0.040 | ≤0.015 | 15.0–17.0 | 4.0–6.0 | 0.8–1.5 | ≤0.02 |

Mechanical Properties (After Standard Heat Treatment)

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Impact Toughness (–40°C, J) |

|---|---|---|---|---|---|

| Solution Annealed | 750–900 | 550–700 | 15–25 | 220–280 | ≥60 |

| Aged (550°C × 4h) | 900–1100 | 700–900 | 12–18 | 280–350 | ≥50 |

- Solution Annealing: 1020–1050°C × 30 min, followed by oil or air cooling.

- Aging (Precipitation Hardening): 480–550°C × 2–4 h, air cooled.

This dual-step process develops a fine dispersion of ε-Cu and Ni₃Ti precipitates, delivering peak strength without compromising toughness.

Physical Properties

| Property | Value |

|---|---|

| Density (20°C) | 7.8 g/cm³ |

| Melting Range | 1420–1460°C |

| Thermal Conductivity (100°C) | 15 W/(m·K) |

| Specific Heat (20°C) | 500 J/(kg·K) |

| Electrical Resistivity | 0.85 µΩ·m |

| Coefficient of Thermal Expansion (20–100°C) | 11.5 × 10⁻⁶ /K |

Applications

- Marine Engineering: Propeller shafts, rudder stocks, seawater pump components, offshore platform connectors.

- Oil & Gas: Downhole tools, high-pressure valves, subsea manifolds, sour service equipment (H₂S environments).

- Aerospace: Landing gear parts, turbine blades, fasteners requiring high fatigue resistance.

- Energy: Hydro turbine runners, nuclear reactor internals, steam generator tubes.

- Precision Machinery: High-strength spindles, molds, measuring instruments, and wear-resistant shafts.

Machining & Fabrication Guidelines

| Process | Recommended Parameters | Tooling Suggestions |

|---|---|---|

| Turning | Speed: 60–90 m/min; Feed: 0.1–0.2 mm/rev | Coated carbide inserts |

| Milling | Speed: 50–80 m/min; Feed: 0.05–0.15 mm/tooth | Ceramic or PVD-coated tools |

| Drilling | Speed: 15–25 m/min; Feed: 0.05–0.1 mm/rev | Cobalt HSS or solid carbide |

| Grinding | Wheel speed: 20–30 m/s | CBN or aluminum oxide wheels |

Welding Recommendations

- Preferred Method: GTAW (TIG) with ER2209 filler wire and Ar + 2% O₂ shielding gas.

- Interpass Temperature: Keep ≤150°C to avoid sensitization.

- Heat Input: Maintain between 5–15 kJ/cm.

- Post-Weld Treatment: Full solution annealing (1050°C × 30 min, water quench) is advised for critical corrosion service. Alternatively, localized stress relief at 850°C can reduce residual stresses.

Comparison with Common Stainless Grades

| Property | 1.4418 | 1.4462 (2205) | 316L | 17-4PH |

|---|---|---|---|---|

| Tensile Strength (MPa) | 900–1100 | 620–800 | 485 | 1310 |

| Yield Strength (MPa) | 700–900 | 450–550 | 170 | 1170 |

| Elongation (%) | 12–18 | 25 | 40 | 10 |

| PREN | ≥35 | ≥35 | ~25 | ~18.5 |

| Weldability | Excellent | Excellent | Excellent | Moderate |

| Cost Efficiency | High (vs. duplex) | Medium | Low | High |

Quality Assurance & Certifications

- EN 10272 (stainless steel bars for pressure purposes)

- ASTM A743/A744 (cast equivalents: CA6NM)

- NORSOK M-001 (for offshore applications)

- PED 2014/68/EU (Pressure Equipment Directive)

Available Sizes & Finishes

- Diameters: 10 mm to 300 mm (standard); custom sizes available.

- Lengths: 2000–6000 mm (cut-to-length upon request).

- Surface Finish: Precision ground (h9 tolerance), polished (optional Ra 0.4 µm).

- Packaging: VCI paper + wooden crates for export; moisture-controlled storage.

Why Choose Our 1.4418 Round Bars?

- Consistent Quality: Melted via EAF + AOD for ultra-low impurities (S < 0.015%).

- Traceability: Full heat number tracking from ingot to finished bar.

- Global Supply: Ready stock in Europe, Asia, and North America.

- Technical Support: Metallurgical consultation for heat treatment, welding, and design optimization.