-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

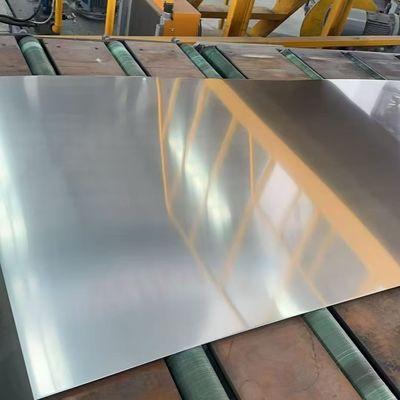

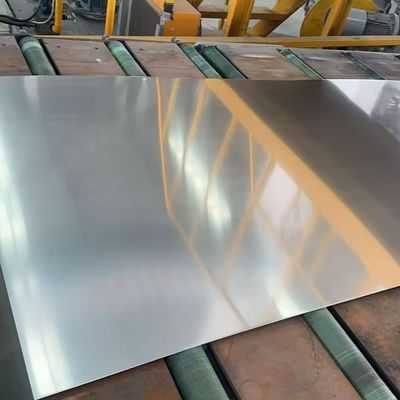

317L Stainless Steel Plate Sheet 2B NO.1 Surface 0.6 - 30.0mm With 4ft*8ft And 5ft*20ft

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 317L / S31703 |

| Minimum Order Quantity | 500 kgs |

| Price | 5000 - 7200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Plate | Grade | 317L / S31703 |

|---|---|---|---|

| Thickness | 0.6 - 30.0mm | Width | 1219mm 1500mm 1800mm 2000mm |

| Surface | NO.1 2B | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | 5ft*20ft 317L Stainless Plate Sheet,317L Stainless Steel Plate Sheet,317L Stainless Plate Sheet 30.0mm |

||

317L Stainless Steel Plate Sheet 2B NO.1 Surface 0.6 - 30.0mm With 4ft*8ft and 5ft*20ft

Products Specification

| Products Name | 317L Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 317L, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,654SMO,253MA,2205,2507.etc |

| Thickness | 0.6 - 30.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

Introduction to 317L Stainless Steel Plate & Sheet

317L stainless steel plate and sheet represent the flat-rolled product forms of the 317L alloy. While inheriting the core chemical composition and general properties of 317L stainless steel, the plate/sheet form introduces specific considerations related to manufacturing processes, dimensional characteristics, typical applications, and handling relevant to flat products.

Key Differentiators for Plate/Sheet vs. General Material

-

Product Form & Dimensional Focus:

-

Plate: Generally refers to thicker flat products, typically starting around 5mm (3/16 inch) and going up to significant thicknesses (e.g., 100mm+). Characterized by greater structural strength and load-bearing capacity.

-

Sheet: Refers to thinner flat products, usually below 5mm (down to foil gauges). Offers greater flexibility and formability for bending, stamping, and drawing.

-

Standards: Governed by specifications like ASTM A240/A240M (Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications), ASME SA-240, EN 10088-2, etc. These define chemical, mechanical, and dimensional tolerances specifically for flat products.

-

-

Manufacturing Process Impact:

-

Hot Rolling: Plates and thicker sheets are primarily produced by hot rolling at high temperatures. This process:

-

Results in a scaled surface that requires subsequent descaling (e.g., pickling, abrasive blasting).

-

May lead to slightly different microstructures and residual stresses compared to cold-rolled products.

-

Offers good through-thickness properties but potentially slightly less precise dimensional control than cold rolling.

-

-

Cold Rolling: Used for thinner sheets and to achieve specific finishes or tighter tolerances. Cold rolling:

-

Produces smoother surfaces with a range of standard finishes (e.g., 2B, BA, No. 4).

-

Significantly increases strength and hardness (work hardening) while reducing ductility compared to the annealed hot-rolled state.

-

Requires a final solution annealing treatment after cold rolling to restore optimal corrosion resistance and ductility.

-

Offers superior dimensional accuracy and surface finish control.

-

-

Annealing & Pickling: Crucial for plate/sheet. After hot rolling or cold rolling + cold working, plates/sheets undergo solution annealing (heating to ~1900-2050°F / 1040-1120°C followed by rapid quenching) to dissolve carbides and restore corrosion resistance. This is followed by pickling to remove oxide scale formed during annealing.

-

-

Surface Finish Options (Critical for Sheet):

-

Hot-Rolled Plate: Typically supplied with a descaled (pickled) surface (e.g., No. 1 finish). Grinding or polishing may be specified.

-

Cold-Rolled Sheet: Offers a variety of standard finishes:

-

2B: Bright, smooth, moderately reflective finish (most common general-purpose finish).

-

BA (Bright Annealed): Highly reflective, smooth mirror-like finish. Excellent for aesthetic applications or where easy cleanability is paramount.

-

No. 4 (Brushed): Directional satin finish, often used for architectural or decorative applications.

-

No. 8 (Mirror): Highly polished mirror finish.

-

Polished (to specific Ra): Custom roughness average specifications.

-

-

-

Thickness-Dependent Properties & Considerations:

-

Corrosion Performance: While the alloy inherently resists pitting/crevice corrosion, thinner sections might be more susceptible to perforation if localized corrosion initiates. Thicker plate offers greater corrosion allowance.

-

Weldability: Welding procedures for plate (especially thick plate) require careful control of heat input and interpass temperatures to manage distortion and potential sensitization at the heat-affected zone (HAZ), although the low carbon minimizes this risk. Pre/post-weld heat treatment might be specified for thick sections under severe service conditions. Fit-up for welding large plates is critical.

-

Formability: Sheet exhibits excellent formability (bending, deep drawing, stretch forming) in the annealed condition. Plate formability is significantly lower, especially for thicker gauges; forming typically requires specialized equipment (e.g., press brakes, plate rolls). Cold-worked sheet will have reduced formability compared to annealed sheet.

-

Mechanical Properties: While meeting the minimums in ASTM A240, actual yield/tensile strength can vary slightly based on thickness and processing route. Cold-rolled sheet will have higher strength than annealed hot-rolled plate of the same nominal thickness.

-

-

Typical Applications Leveraging the Plate/Sheet Form:

-

Chemical & Petrochemical Processing:

-

Plate: Fabricated pressure vessel shells, reactor linings, large tank walls, column trays, heavy-duty ductwork, flue gas absorber modules (FGD).

-

Sheet: Liner sheets for tanks/vessels, chutes, hoppers, covers, baffles, smaller tanks/vessels.

-

-

Pollution Control (FGD): Large absorber tower shells, duct sections, mist eliminator supports (Plate); liner sheets (Sheet).

-

Pulp & Paper: Digester vessels, bleach washer drums (Plate); covers, chutes (Sheet).

-

Marine & Offshore: Hull plating in specific areas requiring enhanced corrosion resistance (Plate - though often clad); architectural panels, enclosures (Sheet).

-

Architectural & Building: Cladding panels, roofing, decorative elements (primarily Sheet in finishes like BA, No. 4).

-

Food & Pharmaceutical: Equipment surfaces, workbenches, tanks, hoppers (Sheet, often with BA or polished finishes for hygiene).

-

Heat Exchangers: Fabricated plates or shells for corrosive service (Plate/Sheet).

-

Key Considerations for Specifying/Using 317L Plate & Sheet

-

Specify the Standard & Condition: Clearly state the governing standard (e.g., ASTM A240), product form (Plate or Sheet), thickness, width/length, condition (e.g., Annealed, Annealed & Pickled, Cold Rolled Annealed & Pickled), and required surface finish (e.g., 2B, BA, No. 4, Hot Rolled Pickled).

-

Thickness Tolerance: Understand the permissible thickness variations per the relevant standard (e.g., ASTM A480 covers general tolerances for stainless plate/sheet).

-

Flatness & Edge Condition: Requirements vary based on thickness and application (e.g., sheared, slit, mill edge, trimmed edge).

-

Handling & Fabrication: Protect surfaces during handling/storage. Use proper tools and techniques for cutting (shearing, plasma, laser, waterjet), forming, and welding to preserve corrosion resistance and avoid contamination (e.g., iron embedding). Clean thoroughly before service.

Summary

317L stainless steel plate and sheet deliver the enhanced molybdenum-boosted corrosion resistance of the base alloy in versatile flat forms. The key differences lie in the manufacturing processes (hot/cold rolling, annealing, finishing), dimensional characteristics (thickness ranges, tolerances), specific surface finishes available (especially for sheet), and thickness-dependent application considerations (formability, weldability, structural role). Understanding these product-form-specific attributes is essential for selecting the right gauge, condition, and finish for demanding applications in chemical processing, pollution control, marine architecture, and other industries where flat components are subjected to aggressive environments.

![]()

![]()

![]()

![]()