All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

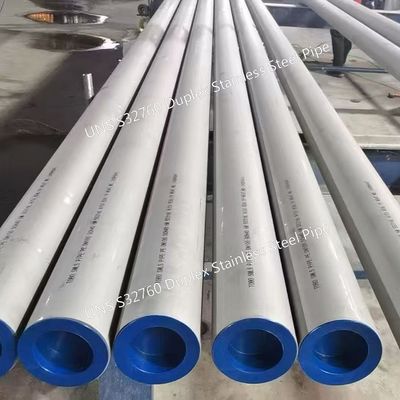

S32760 Super Duplex Stainless Steel Pipe High PREN Superior Chloride Resistance Seamless / Welded

Product Details

| Products | Stainless Steel Seamless Pipe | Grade | S32760 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | superior chloride resistance S32760 pipe,S32760 Super Duplex Stainless Pipe |

||

Product Description

S32760 Super Duplex Stainless Steel Pipe High PREN Superior Chloride Resistance, Seamless/Welded

Products Specification

| Products Name | s32760 Duplex Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

S32760 Duplex Stainless Steel Pipe: A Specialized Engineering Marvel

S32760, denoted by its UNS designation, stands as a super duplex stainless steel renowned for its hybrid microstructure and extreme environmental resilience. Here’s a fresh perspective on its technical nuances and modern applications:

Alloy Composition and Microstructural Synergy

The alloy's composition is a strategic blend designed for harsh service conditions:

- 25% Chromium: Enhances oxidation resistance in high-temperature environments.

- 7% Nickel with 4.5% Molybdenum: Forms a protective layer against chloride-induced stress corrosion.

- 1% Tungsten Addition: Elevates pitting resistance in acidic media, a key advantage over standard duplex grades.

- 0.25% Nitrogen: Strengthens the lattice structure while maintaining ductility.

This dual-phase matrix (ferrite-austenite) creates a unique synergy, combining the best of both phases: ferrite’s strength and austenite’s toughness.

Mechanical Attributes for Demanding Systems

- Tensile Strength: Exceeds 750 MPa, ideal for high-pressure pipelines (up to 10,000 psi).

- Impact Resistance: Retains ≥80 J at -50°C, critical for Arctic oil projects.

- Fatigue Limit: Withstands over 10⁷ cycles under cyclic loading, suitable for offshore platforms subject to wave motion.

- Creep Rupture Strength: Maintains 90% of yield strength at 300°C for 10,000 hours, outperforming 6Mo alloys in prolonged high-temperature use.

Corrosion Resistance in Extreme Scenarios

- Sour Oil & Gas: Complies with NACE MR0103 for H₂S environments (up to 30,000 ppm) and resists chloride stress corrosion cracking (CSCC) in brines with 150,000 ppm Cl⁻.

- Marine & Desalination: Tolerates seawater velocities up to 15 m/s without erosion-corrosion, making it suitable for seawater intake systems.

- Chemical Processing: Handles 50% sulfuric acid at 60°C and 30% phosphoric acid at 80°C, common in fertilizer plants.

- Aqueous Chloride Media: Resists pitting at free chlorine concentrations up to 200 ppm, critical for water treatment facilities.

Innovative Industry Applications

-

Deepwater Subsea Infrastructure:

- Used in 3,000m+ depth pipelines for projects like the Brazilian pre-salt fields, where high pressure and H₂S pose dual challenges.

- Connectors and riser systems in floating production storage and offloading (FPSO) vessels.

-

Renewable Energy:

- Heat exchangers in concentrated solar power (CSP) plants, resisting molten salt corrosion at 550°C.

- Offshore wind farm foundations exposed to tidal zones with high chloride content.

-

Nuclear & Aerospace:

- Secondary cooling systems in nuclear reactors, tolerating radioactive water and high temperatures.

- Fuel transport lines in aerospace ground support equipment, resistant to jet fuel additives.

-

Chemical Tankers:

- Cargo pipelines for transporting chlorinated hydrocarbons and organic acids.

Fabrication and Installation Innovations

- Advanced Welding Techniques: Laser beam welding (LBW) reduces heat input, minimizing sigma phase formation.

- Cold Expansion Processes: Enhances fatigue life by 20% for pipe joints in cyclic loading applications.

- Non-Destructive Testing (NDT): Phased array ultrasonic testing (PAUT) ensures 100% weld penetration in thick-walled pipes (up to 50mm).

- Coating Compatibility: Bonds well with fusion-bonded epoxy (FBE) coatings for subsea cathodic protection.

Standards and Modern Specifications

- API 6A (20th Edition): Certified for equipment in sour gas wells.

- ISO 15156-3: Meets requirements for materials in H₂S-containing oil and gas production.

- AD 2000-Merkblatt W0: Approved for pressure vessels in the European Union.

- NORSOK M-630: Complies with Norwegian offshore corrosion standards for subsea components.

Comparative Technical Matrix

| Attribute | S32760 | 2507 Super Duplex | 904L Austenitic |

|---|---|---|---|

| PREN Value | 43–46 | 40–42 | 34–36 |

| Service Temperature | -60°C to 350°C | -50°C to 250°C | -196°C to 200°C |

| H₂S Pressure Limit | 10 MPa | 6 MPa | 2 MPa |

| Cost per Ton | $8,500–$10,000 | $7,000–$8,000 | $6,000–$7,000 |

Sustainability and Life Cycle Benefits

- Longevity: Expected service life of 50+ years in offshore environments, reducing replacement needs.

- Low Maintenance: Requires no internal lining or cathodic protection in most applications, cutting operational costs.

- Circular Economy: Recycled alloys maintain 95% of original properties, with 80% of S32760 pipes sourced from scrap in Europe.

- Carbon Footprint: 30% lower CO₂ emissions per ton compared to nickel-based alloys like Inconel 625.

Conclusion: A Material for the Next Generation

S32760 duplex pipe transcends traditional stainless steel limitations, serving as a cornerstone in industries pushing the boundaries of engineering—from deep-sea exploration to next-gen energy systems. Its ability to withstand simultaneous mechanical stress and chemical attack positions it as an indispensable material for projects where reliability is non-negotiable.

Recommended Products