-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

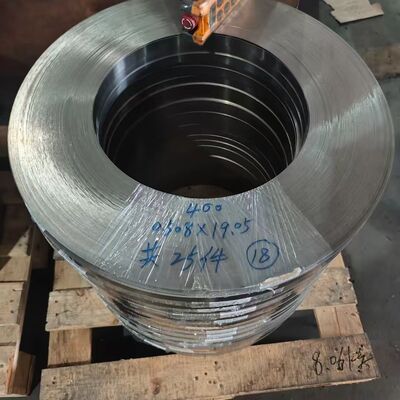

Inconel 625 (UNS N06625) Nickel-Chromium-Molybdenum Alloy Strip Excellent Oxidation Resistance

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 600,625,718,800,c276,400.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 22 - 30 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

| Products | Nickel Alloy Sheet & Plate | Grade | 600,625,718,800,c276,400.etc |

|---|---|---|---|

| Thickness | 0.05 - 30.0mm | Width | Custom Slit Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B BA |

| Highlight | Inconel 625 alloy strip,Nickel-chromium-molybdenum alloy strip,Oxidation resistant Inconel 625 |

||

Inconel 625 (UNS N06625) Nickel-Chromium-Molybdenum Alloy Strip Excellent Oxidation Resistance

Products Specification

| Products Name | UNS N06625 Nickel Alloy Strips |

| Thickness | 0.05 - 3.0mm |

| Width | within 1219mm |

| Surface | 2B BA |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Main Grade | Hastelloy C22 C4 X C276 G35 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 617 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Inconel 625 (UNS N06625) Nickel-Chromium-Molybdenum Alloy Strip – Excellent Oxidation Resistance for Extreme Environments

Product Introduction

Inconel 625, designated as UNS N06625, is a premium nickel-chromium-molybdenum-niobium alloy engineered for exceptional performance in highly corrosive and high-temperature environments. The Inconel 725 strip form—specifically cold-rolled to precise thicknesses and surface finishes—delivers outstanding oxidation resistance up to 1095°C (2000°F), making it a material of choice across aerospace, power generation, chemical processing, and marine engineering sectors.

This product information sheet details the composition, properties, applications, and technical specifications of Inconel 625 alloy strip, emphasizing its superior oxidation resistance and reliability under thermal cycling and aggressive atmospheres.

Why Inconel 625 Excels in Oxidizing Environments

The excellent oxidation resistance of Inconel 625 stems from its unique chemistry:

- Chromium (20–23%) forms a dense, self-healing Cr₂O₃ oxide layer that adheres strongly to the surface, preventing further oxygen diffusion.

- Molybdenum (8–10%) enhances resistance to pitting and crevice corrosion in chloride-rich settings.

- Niobium (3.15–4.15%) stabilizes the microstructure and provides solid-solution strengthening without requiring precipitation hardening.

- High nickel content (>58%) ensures structural stability and ductility across wide temperature ranges.

Unlike many stainless steels that degrade rapidly above 650°C, Inconel 625 maintains integrity even after prolonged exposure to combustion gases, steam, and cyclic heating/cooling.

Key Features

- ✅ Outstanding oxidation resistance up to 1095°C (2000°F)

- ✅ Resists scaling, spalling, and embrittlement during thermal cycling

- ✅ High strength from cryogenic to elevated temperatures

- ✅ Excellent resistance to pitting, crevice corrosion, and stress-corrosion cracking

- ✅ Weldable without post-weld heat treatment

- ✅ Non-magnetic in annealed condition

- ✅ Available in precision cold-rolled strip with tight tolerances

Chemical Composition (UNS N06625 – ASTM B443)

| Element | Typical Range (wt.%) |

|---|---|

| Nickel (Ni) | Balance (>58%) |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium + Tantalum (Nb+Ta) | 3.15 – 4.15 |

| Iron (Fe) | ≤ 5.0 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.015 |

| Aluminum (Al) + Titanium (Ti) | ≤ 0.80 total |

Meets requirements of ASTM B443, AMS 5599, ASME SB-443, and ISO NW 6625.

Oxidation Resistance Performance

| Temperature | Oxidation Rate (Approx.) | Performance Notes |

|---|---|---|

| 650°C (1200°F) | <0.1 mm/year | Negligible scaling; ideal for long-term service |

| 870°C (1600°F) | ~0.2 mm/year | Protective Cr₂O₃ layer remains stable |

| 980°C (1800°F) | ~0.5 mm/year | Suitable for intermittent exposure |

| 1095°C (2000°F) | Limited continuous use | Best for short-term or cyclic applications |

Note: Performance exceeds that of 310 stainless steel and rivals specialized alloys like Haynes 230 in oxidizing atmospheres.

Accelerated testing per ASTM G111 and ISO 21607 confirms minimal weight gain and no spallation after 100+ thermal cycles (25–980°C).

Mechanical Properties (Annealed Condition)

| Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 830 MPa (120 ksi) |

| Yield Strength (0.2% offset) | ≥ 415 MPa (60 ksi) |

| Elongation | ≥ 30% |

| Hardness | ≤ 220 HB / ≤ 100 HRB |

| Modulus of Elasticity | 207 GPa |

Cold working can increase tensile strength to over 1100 MPa while retaining adequate ductility.

Precision Strip Specifications

| Parameter | Range |

|---|---|

| Thickness | 0.025 mm – 3.0 mm |

| Width | 5 mm – 610 mm (custom slitting available) |

| Temper | Annealed (O), ¼ Hard, ½ Hard, Full Hard |

| Surface Finish | 2B, Bright Annealed (BA), Matte, Brushed |

| Tolerance (Thickness) | ±0.005 mm (for precision grades) |

| Coil ID/OD | Standard: 305 mm / 610 mm (custom options) |

Ideal for stamping, forming, laser cutting, and welding into complex components.