-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

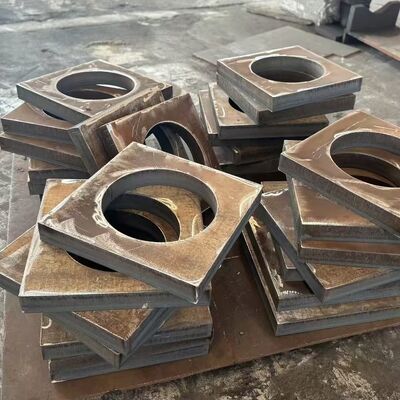

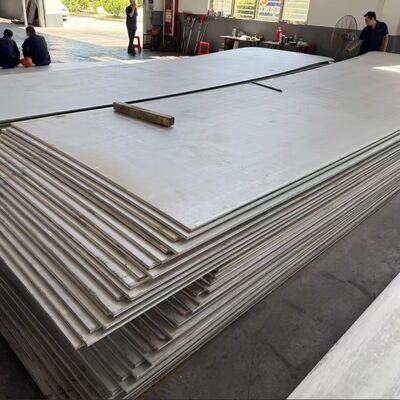

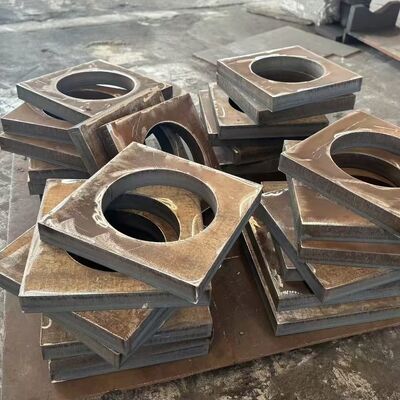

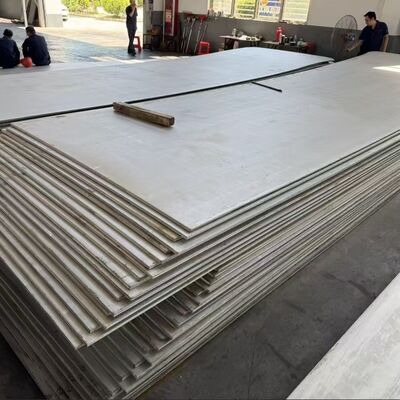

310S Austenitic Stainless Steel Plate Excellent Oxidation Resistance up to 1150°C

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL TISCO |

| Certification | ISO |

| Model Number | 310S / 1.4845 |

| Minimum Order Quantity | 50 kgs |

| Price | 5-8 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Plate | Grade | 310S / 1.4845 / S31008 |

|---|---|---|---|

| Thickness | 0.5-80.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2B BA NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | 310S stainless steel plate,austenitic stainless steel sheet,high-temperature oxidation resistant steel plate |

||

310S Austenitic Stainless Steel Plate Excellent Oxidation Resistance up to 1150°C

Stainless Steel Plate Specifications

| Name | 310S stainless steel Plate |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

310S Austenitic Stainless Steel Plate – Excellent Oxidation Resistance up to 1150°C

Product Overview

310S austenitic stainless steel plate is a premium high-alloy material engineered for extreme thermal environments where oxidation resistance, structural integrity, and long-term reliability are non-negotiable. With a composition of 25% chromium and 20% nickel, and an ultra-low carbon content (≤0.08%), 310S delivers outstanding performance in continuous service temperatures up to 1150°C (2100°F)—making it one of the most heat-resistant stainless steels available without resorting to costly nickel-based superalloys.

Unlike standard grades like 304 or 316, which degrade rapidly above 800°C, 310S maintains its mechanical strength, resists scaling, and forms a stable, self-healing chromium oxide layer even under prolonged exposure to air, combustion gases, or mildly carburizing atmospheres. This makes it the material of choice for furnace components, thermal processing equipment, petrochemical reactors, and energy systems operating at the edge of conventional metallurgy.

Available in hot-rolled or forged plate formats with thicknesses from 3 mm to over 100 mm, 310S combines industrial robustness with fabricability—ideal for heavy-duty applications demanding both durability and precision.

Why 310S Excels at High Temperatures

The exceptional performance of 310S stems from its carefully balanced chemistry:

- Chromium (24–26%): Forms a dense, adherent Cr₂O₃ scale that dramatically slows further oxidation.

- Nickel (19–22%): Stabilizes the austenitic structure, preventing embrittlement and maintaining ductility at elevated temperatures.

- Low Carbon (<0.08%): The “S” denotes special low-carbon, minimizing chromium carbide precipitation during welding or high-temp exposure—thus preserving corrosion and oxidation resistance in heat-affected zones.

This synergy enables 310S to outperform not only common stainless grades but also many heat-resistant alloys in oxidizing conditions.

Key Properties & Advantages

| Property | Benefit |

|---|---|

| Max Continuous Service Temp | 1150°C (2100°F) in air |

| Intermittent Use Temp | Up to 1040°C (1900°F) with thermal cycling |

| Oxidation Resistance | Excellent—minimal scale formation or spalling |

| Carburization Resistance | Good in moderately carburizing atmospheres |

| Creep & Rupture Strength | Superior among stainless steels at >900°C |

| Weldability | Excellent with matching 310/312 fillers; no post-weld annealing needed |

| Non-Magnetic | In annealed condition—suitable for sensitive environments |

| Thermal Fatigue Resistance | Withstands repeated heating/cooling cycles |

Technical Specifications

| Parameter | Value / Standard |

|---|---|

| Grade Designation | AISI 310S / UNS S31008 / EN 1.4845 / JIS SUS310S |

| Chemical Composition (wt%) | Cr: 24–26%, Ni: 19–22%, C: ≤0.08%, Mn: ≤2.0%, Si: ≤1.5%, P: ≤0.045%, S: ≤0.030% |

| Plate Thickness Range | 3 mm to 150 mm (standard); custom up to 200 mm |

| Common Plate Sizes | 1500 × 6000 mm, 2000 × 6000 mm, 2500 × 12000 mm |

| Density | 7.9 g/cm³ |

| Melting Range | 1400–1450°C (2550–2650°F) |

| Thermal Conductivity | 13.6 W/m·K at 100°C |

| Coefficient of Thermal Expansion | 14.4 µm/m·°C (20–100°C) |

| Tensile Strength (RT) | ≥520 MPa |

| Yield Strength (0.2% offset) | ≥205 MPa |

| Elongation | ≥40% |

| Standards Compliance | ASTM A240, ASME SA-240, EN 10088-2, ISO 15510 |

Industrial Applications

310S plate is specified wherever extreme heat meets structural demand:

| Industry | Key Components |

|---|---|

| Heat Treatment | Furnace muffles, radiant tubes, retorts, conveyor rails, sintering trays |

| Petrochemical & Refining | Cracking furnace tubes, reformer manifolds, flue gas ducts |

| Power Generation | Biomass boiler liners, superheater supports, waste-to-energy grates |

| Cement & Lime Production | Kiln inlet chambers, calciner components, burner pipes |

| Glass Manufacturing | Forehearth roofs, stirrers, forming molds |

| Aerospace | Exhaust shrouds, afterburner housings (static parts) |

| Incineration | Combustion chambers, ash discharge systems, flue liners |

Surface Finish & Delivery Condition

- Hot-Rolled, Annealed & Pickled (No.1 Finish): Standard for plate; matte surface with scale removed—ready for fabrication.

- As-Rolled (Black Scale): Available for cost-sensitive applications where surface finish isn’t critical.

- Custom Finishes: Machined, blasted, or ground surfaces upon request for precision fit-up.

All plates undergo ultrasonic testing (UT) on request for critical applications (e.g., pressure vessels).

Fabrication Guidelines

Cutting:

- Plasma, oxy-fuel (with caution), or abrasive sawing recommended.

- Laser cutting possible for thinner sections (<25 mm).

Machining:

- Work-hardens rapidly—use slow speeds, high feed rates, and sharp carbide tools.

- Coolants essential to control heat buildup.

Forming:

- Hot forming preferred above 900°C for thick plates.

- Cold forming feasible for thinner gauges with generous bend radii.

Welding:

- Use ER310 or ER312 filler metals.

- No preheat required; interpass temp <150°C.

- Post-weld heat treatment not required due to low carbon content.

310S vs. Alternatives at High Temperature

| Material | Max Temp (°C) | Oxidation Resistance | Cost Index | Best For |

|---|---|---|---|---|

| 310S | 1150 | ★★★★★ | $$ | General high-temp oxidizing service |

| 309S | 1000 | ★★★☆☆ | $ | Lower-cost alternative below 1000°C |

| 316L | 870 | ★★☆☆☆ | $ | Not suitable for sustained high heat |

| Inconel 600 | 1150 | ★★★★★ | $$$$ | Extreme environments; higher strength needed |

| Alloy 800H | 1100 | ★★★★☆ | $$$ | Reducing/carburizing atmospheres |

✅ 310S offers the best value for oxidizing atmospheres up to 1150°C.

Maintenance & Service Life

- Inspect periodically for warping, excessive scaling, or cracking in cyclic operations.

- Clean with non-chloride agents if exposed to process contaminants.

- Avoid rapid quenching—thermal shock can induce microcracks.

- With proper design and operation, service life exceeds 10–20 years in continuous high-temp applications.

Sustainability & Certification

- Fully recyclable with high scrap recovery value.

- Mill Test Reports (EN 10204 3.1) provided with full chemical and mechanical data.

- Compliant with ASME Section II, PED 2014/68/EU, and ISO 9001 quality systems.

- Supports net-zero initiatives by enabling efficient, long-life thermal systems.

Conclusion

310S austenitic stainless steel plate is the benchmark for high-temperature oxidation resistance in industrial engineering. Its unique blend of chromium, nickel, and controlled carbon content ensures unmatched reliability in furnaces, reactors, and energy systems operating near the limits of conventional materials.

Whether you’re designing a next-generation incinerator or upgrading legacy thermal equipment, 310S delivers proven performance, global code acceptance, and lifecycle cost savings—degree after degree, year after year.

Request a Quote or Mill Certificate Today

Contact our technical sales team for thickness availability, cut-to-size options, or high-temperature design consultation. Trust your heat to the steel that won’t quit.

![]()

![]()

![]()

![]()