-

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

310S Austenitische Edelstahlplatte Ausgezeichnete Oxidationsbeständigkeit bis zu 1150 °C

| Herkunftsort | China |

|---|---|

| Markenname | BAOSTEEL TISCO |

| Zertifizierung | ISO |

| Modellnummer | 310S / 1,4845 |

| Min Bestellmenge | 50 kg |

| Preis | 5-8 USD/Kg |

| Verpackung Informationen | Standardverpackung für den Exportieren |

| Lieferzeit | 5 - 12 Tage basierend auf der Menge |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 20ton pro Woche |

| Produkte | Edelstahlplatte | Grad | 310S / 1.4845 / S31008 |

|---|---|---|---|

| Dicke | 0,5–80,0 mm | Technik | kaltgewalzt, warmgewalzt, geschmiedet |

| Breite | 1000mm 1219mm 1500mm oder Gewohnheiten als Antrag | Oberfläche | 2B BA No.1 |

| Standard | ASTM GB JIS EN-LÄRM | Mindestbestellmenge | 1 Tonne |

| Hervorheben | Platte des Edelstahl-310s,Austenitisches Edelstahlblech,Hochtemperatur-oxidationsbeständige Stahlplatte |

||

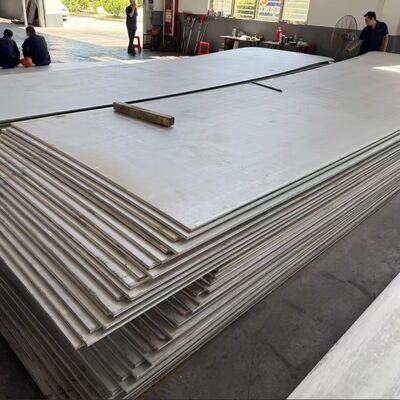

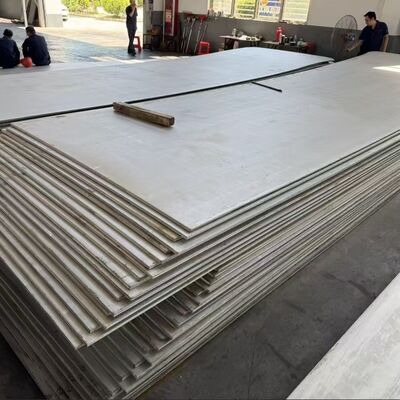

310S Austenitische Edelstahlplatte hervorragende Oxidationsbeständigkeit bis 1150°C

Spezifikationen für Edelstahlplatten

| Name | 310S Edelstahlplatte |

| Unsere Note |

200-Serie: 201 202 300-Serie: 301 304, 304L 304H 309S 310S314,316L,316Ti,316H,316LN,317L,321,329,347 400-Serie: 409L,410,410S,416,420,430,431436 L.439,441,443,444,445,446 Super rostfreier Stahl: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH. usw. Nickellegierung: C276, C22, G35, Legierung X, Monel 400, K500, Inconel 600,601,617,625,718"Inkoloy 800,800H,800HT,825. usw. |

| Technik | Warmgewalzt, kaltgewalzt, gefälscht |

| Standards | JIS, AISI, ASTM, DIN, TUV, BV, SUS usw. |

| Stärke | 0.1 ¢ 80,0 mm |

| Breitenbereich | 10 mm 2000 mm |

| Länge | Individualisiert |

| Beenden Sie. | 2B, BA, Nein.4, 8k, gebürstet, Haarlinie, PVD-Beschichtung, Sandblasen |

| Dienstleistungen | Laserschneiden und Biegen |

| Probe | Erhältlich |

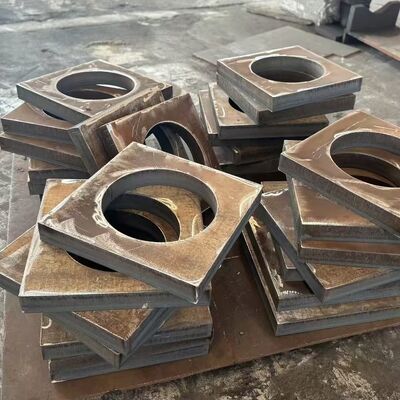

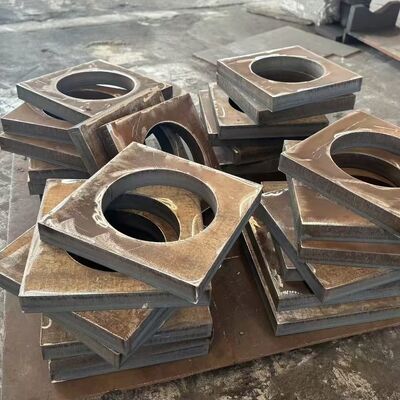

310S Austenitische Edelstahlplatte

Produktübersicht

310S austenitische Edelstahlplatte ist ein hochwertiges hochlegiertes Material, das für extreme thermische Umgebungen entwickelt wurde, in denen Oxidationsbeständigkeit, strukturelle Integrität,und langfristige Zuverlässigkeit sind nicht verhandelbar. mit einer Zusammensetzung von 25% Chrom und 20% Nickel und einem äußerst niedrigen Kohlenstoffgehalt (≤ 0,08%), 310S delivers outstanding performance in continuous service temperatures up to 1150°C (2100°F)—making it one of the most heat-resistant stainless steels available without resorting to costly nickel-based superalloys.

Im Gegensatz zu Standardqualitäten wie 304 oder 316, die sich schnell über 800°C abbauen, behält 310S seine mechanische Festigkeit, widersteht der Abmessung und bildet eine stabile,Selbstheilungsschicht aus Chromoxid, auch bei längerer LuftbelastungDies macht es zum Material der Wahl für Ofenbauteile, Wärmebearbeitungsgeräte, petrochemische Reaktoren,und Energiesysteme, die am Rande der konventionellen Metallurgie arbeiten.

mit einer Dicke von mehr als 100 mm,310S kombiniert industrielle Robustheit mit Fertigbarkeit, ideal für schwere Anwendungen, die sowohl Haltbarkeit als auch Präzision erfordern.

Warum 310S bei hohen Temperaturen hervorragend arbeitet

Die außergewöhnliche Leistungsfähigkeit von 310S beruht auf seiner sorgfältig ausgewogenen Chemie:

- Chromium (2426%): bildet eine dichte, anhängliche Cr2O3-Skala, die die weitere Oxidation dramatisch verlangsamt.

- Nickel (19 ∼22%): Stabilisiert die austenitische Struktur, verhindert Zerbrechlichkeit und behält die Duktilität bei erhöhten Temperaturen.

- Low Carbon (<0,08%): Das S steht für spezielle CO2-arme Stoffe,Verringerung der Chromkarbid-Ausfälle während des Schweißens oder der Hochtemperaturbelastung, wodurch die Korrosions- und Oxidationsbeständigkeit in hitzebelasteten Zonen erhalten bleibt.

Diese Synergie ermöglicht es 310S, nicht nur übliche Edelstahlverbindungen, sondern auch viele hitzebeständige Legierungen unter Oxidationsbedingungen zu übertreffen.

Hauptmerkmale und Vorteile

| Eigentum | Nutzen |

|---|---|

| Maximale Dauerbetriebstemperatur | 1150°C (2100°F) in der Luft |

| Intermittierende Nutzungszeit | Bis zu 1040 °C (1900 °F) mit thermischem Radfahren |

| Oxidationsbeständigkeit | Ausgezeichnet minimale Schuppenbildung oder Spalling |

| Vergasungsbeständigkeit | Gut in moderat karborierenden Atmosphären |

| Kriech- und Rissfestigkeit | Überlegen unter den Edelstahlen bei > 900 °C |

| Schweißbarkeit | Ausgezeichnet mit passenden 310/312-Füllstoffen; keine Nachschweißglühen erforderlich |

| nicht magnetisch | In gegrilltem Zustand |

| Wärmebelastungsbeständigkeit | Widerstandsfähig gegen wiederholte Heiz-/Kühlzyklen |

Technische Spezifikation

| Parameter | Wert / Norm |

|---|---|

| Bezeichnung der Klasse | Einheitliche Prüfverfahren für die Bestimmung der Konzentration von Stoffen und Stoffen |

| Chemische Zusammensetzung (wt%) | Der Anteil der Brennstoffe an der Brennstoffmenge beträgt 0,5% des Brennstoffs. |

| Plattendicke | 3 mm bis 150 mm (Standard); nach Maß bis 200 mm |

| Allgemeine Plattengrößen | Bei der Prüfung der Einhaltung der Vorschriften des Artikels 4 Absatz 1 Buchstabe a der Verordnung (EG) Nr. 715/2009 ist die Kommission verpflichtet, die in Anhang I der Verordnung (EG) Nr. 715/2009 aufgeführten Anforderungen zu erfüllen. |

| Dichte | 70,9 g/cm3 |

| Schmelzbereich | Bei der Herstellung von Zellstoff ist die Zellstoffdioxiddioxiddioxidentwicklung durch die Herstellung von Zellstoffen zu bewerten. |

| Wärmeleitfähigkeit | 13.6 W/m·K bei 100°C |

| Koeffizient der thermischen Ausdehnung | 14.4 μm/m·°C (20°100°C) |

| Zugfestigkeit (RT) | ≥ 520 MPa |

| Ertragsstärke (0,2% Offset) | ≥205 MPa |

| Verlängerung | ≥ 40% |

| Normenkonformität | Die in Absatz 1 genannten Anforderungen gelten nicht für die in Absatz 1 genannten Produkte. |

Industrieanwendungen

310S-Platte wird dort angegeben, wo extreme Hitze den strukturellen Anforderungen entspricht:

| Industrie | Schlüsselkomponenten |

|---|---|

| Wärmebehandlung | Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen, Schleifen |

| Petrochemie und Raffination | Rohre für Spaltöfen, Reformeranlagen, Rauchgasleitungen |

| Stromerzeugung | Biomasse-Kesselfolien, Überhitzerstützen, Abfall-zu-Energie-Gitter |

| Produktion von Zement und Kalk | Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelzflächen, Schmelz |

| Glasherstellung | Vorwälzdecken, Rührgeräte, Formen |

| Luft- und Raumfahrt | Auspuffhüllen, Gehäuse für Nachbrenner (statische Teile) |

| Verbrennung | Verbrennungskammern, Aschausschüttungssysteme, Rauchbehälter |

Oberflächenbearbeitung und Lieferzustand

- Warmgewalzt, gegrillt und eingelegt (Ausführung Nr. 1): Standard für Platten; matte Oberfläche mit entferntem Schuppen, fertig zur Herstellung.

- Als gewalzt (Schwarze Skala): Erhältlich für kostensensitive Anwendungen, bei denen die Oberflächenveredelung nicht kritisch ist.

- Besondere Veredelungen: Bearbeitete, geblasene oder gemahlene Oberflächen auf Anfrage für eine präzise Anpassung.

Alle Platten werden auf Anfrage für kritische Anwendungen (z. B. Druckbehälter) einer Ultraschallprüfung (UT) unterzogen.

Herstellungsrichtlinien

Schnitt:

- Plasma, Oxy-Fuel (mit Vorsicht) oder Schleifsäge empfohlen.

- Laserschnitt möglich für dünnere Abschnitte (< 25 mm).

Bearbeitung:

- Die Arbeit wird schnell gehärtet, wenn man mit langsamen Geschwindigkeiten, hohen Zufuhrraten und scharfen Werkzeugen aus Karbid arbeitet.

- Kühlmittel, die für die Kontrolle der Wärmeansammlung unerlässlich sind.

Verformung:

- Bei dicken Platten wird die Warmformung über 900 °C bevorzugt.

- Kaltformung für dünnere Messungen mit großzügigen Biegeradien möglich.

Schweißen:

- Verwenden Sie Füllmetalle ER310 oder ER312.

- Es ist keine Vorwärmung erforderlich; Zwischenpassentemperatur < 150°C.

- Wärmebehandlung nach dem Schweißen aufgrund des geringen Kohlenstoffgehalts nicht erforderlich.

310S vs. Alternativen bei hoher Temperatur

| Material | Höchsttemperatur (°C) | Oxidationsbeständigkeit | Kostenindex | Am besten für |

|---|---|---|---|---|

| 310S | 1150 | Ich bin nicht derjenige. | - Ich weiß nicht. | Allgemeiner Hochtemperatur-Oxidationsdienst |

| 309S | 1000 | Ich habe dich nicht gesehen. | $ | Kostengünstigere Alternative unter 1000°C |

| 316L | 870 | Ich habe dich nicht gesehen. | $ | Nicht geeignet für anhaltend hohe Hitze |

| Inkonel 600 | 1150 | Ich bin nicht derjenige. | - Ich bin nicht derjenige. | Extreme Umgebungen; höhere Festigkeit erforderlich |

| Legierung 800H | 1100 | Ich bin nicht derjenige. | - Ich weiß nicht. | Verringerung/Vergasung von Atmosphären |

✅ 310S bietet den besten Wert für Oxidationsatmosphären bis zu 1150°C.

Wartung und Lebensdauer

- Überprüfen Sie in regelmäßigen Abständen, ob bei zyklischen Arbeiten keine Verformung, übermäßige Vergrößerung oder Rissbildung auftritt.

- Reinigung mit Nichtchloridmitteln, wenn sie Prozesskontaminanten ausgesetzt sind.

- Vermeiden Sie ein schnelles Löschen. Wärmeschock kann zu Mikrokrecken führen.

- Bei ordnungsgemäßem Aufbau und Betrieb übersteigt die Lebensdauer bei kontinuierlichen Anwendungen bei hohen Temperaturen 10~20 Jahre.

Nachhaltigkeit und Zertifizierung

- Vollständig recycelbar mit hohem Wert für die Rückgewinnung von Schrott.

- Prüfberichte für Mühlen (EN 10204 3.1) mit vollständigen chemischen und mechanischen Daten.

- Einheitliche Qualitätssicherungsanlagen, die die Anforderungen an die Qualitätssicherung von Fahrzeugen erfüllen

- Unterstützung von Netto-Null-Initiativen durch effiziente, langlebige Wärmesysteme.

Schlussfolgerung

310S austenitische Edelstahlplatte ist der Maßstab für die Hochtemperatur-Oxidationsbeständigkeit in der Industrie.und kontrollierter Kohlenstoffgehalt sorgt für eine unübertroffene Zuverlässigkeit in Öfen, Reaktoren und Energiesysteme, die in der Nähe der Grenzen herkömmlicher Materialien arbeiten.

Egal, ob Sie eine Verbrennungsanlage der nächsten Generation entwerfen oder alte thermische Geräte aufwerten, 310S bietet bewährte Leistung, globale Akzeptanz und LebenszykluskostenersparnisseJahr für Jahr.

Anfordern Sie heute noch ein Angebot oder ein Mühlzeugnis

Kontaktieren Sie unser technisches Vertriebsteam, um die Verfügbarkeit der Dicke, die Auswahl der Schnitte nach Maß oder die Beratung bei der Konstruktion bei hohen Temperaturen zu erfahren.

![]()

![]()

![]()

![]()