-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

304 Stainless Steel Strips Soft 1/4H 1/2H 3/4H FH SS Strips 2B BA Surface Slit Cutting Without Burr

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Strip | Thickness | 0.1-3.0mm |

|---|---|---|---|

| Width | Within 1219mm | MOQ | 20 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | 304 stainless steel strips soft temper,stainless steel strips 2B BA surface,slit cut stainless steel strips burr-free |

||

304 Stainless Steel Strips Soft 1/4H 1/2H 3/4H FH SS Strips 2B BA Surface Slit Cutting Without Burr

| Products | stainless steel strip |

| Thickness | 0.1-3.0mm |

| Width | minimum width 5mm |

| MOQ | 20 kgs |

| Main Grade | 201 301 304 304L 309S 310S 316L 316Ti 410 420 430 436 439 441 444 440A/B/C,2205,2507,904L,C276,400,600,625,926,825.etc |

| Surface | BA 2B |

| Standard | ASTM EN GB JIS |

| Packing | wooden frame and water proof paper |

304 Stainless Steel Strips: A Comprehensive Guide to Tempers, Surface Finishes, and Slitting Precision

Stainless steel strips are essential components in a wide range of industries—from automotive and aerospace to electronics, medical devices, and consumer goods. Among the most widely used grades is AISI 304 stainless steel, prized for its excellent corrosion resistance, formability, and aesthetic appeal. When processed into thin strips with specific mechanical properties and surface finishes, 304 stainless steel becomes even more versatile. This article explores the key characteristics of 304 stainless steel strips in various tempers (Soft, 1/4H, 1/2H, 3/4H, FH), common surface finishes (2B and BA), and the importance of precision slitting without burrs.

1. Overview of 304 Stainless Steel

Grade 304 (UNS S30400) is an austenitic stainless steel containing approximately 18% chromium and 8% nickel. It offers:

- Excellent resistance to oxidation and corrosion in mild environments

- Good weldability and formability

- Non-magnetic properties in annealed condition (may become slightly magnetic after cold working)

- High ductility and toughness, even at cryogenic temperatures

These attributes make it ideal for strip applications requiring both structural integrity and surface quality.

2. Mechanical Tempers: Soft, 1/4H, 1/2H, 3/4H, and FH

The mechanical properties of stainless steel strips are tailored through controlled cold rolling, which increases strength while reducing ductility. The degree of cold work defines the temper designation:

| Temper | Description | Typical Tensile Strength (MPa) | Yield Strength (0.2% Offset, MPa) | Elongation (%) |

|---|---|---|---|---|

| Soft (Annealed) | Fully annealed; maximum ductility | 515–620 | 205 min | ≥40 |

| 1/4 Hard (1/4H) | Light cold work; moderate strength increase | 585–725 | 275–345 | 25–35 |

| 1/2 Hard (1/2H) | Medium cold work; balanced strength & formability | 725–860 | 345–450 | 15–25 |

| 3/4 Hard (3/4H) | Heavy cold work; high strength, limited formability | 860–1000 | 450–550 | 8–15 |

| Full Hard (FH) | Maximum cold work; very high strength, minimal elongation | ≥1000 | ≥550 | ≤8 |

Application Guidance:

- Soft temper: Ideal for deep drawing, bending, or complex forming operations (e.g., kitchen sinks, automotive trim).

- 1/4H & 1/2H: Common in springs, brackets, and electrical contacts where moderate springback is acceptable.

- 3/4H & FH: Used in flat springs, snap-fit components, and wear-resistant parts requiring high yield strength.

3. Surface Finishes: 2B vs. Bright Annealed (BA)

Surface finish significantly impacts appearance, corrosion resistance, and suitability for secondary processes like plating or painting.

2B Finish

- Achieved by cold rolling followed by heat treatment, pickling, and a light skin-pass rolling.

- Smooth, semi-reflective, matte-gray appearance.

- Most common general-purpose finish.

- Suitable for applications where aesthetics are secondary to function (e.g., industrial equipment, structural parts).

Bright Annealed (BA) Finish

- Produced by annealing in a controlled atmosphere (hydrogen/nitrogen) to prevent oxidation.

- Mirror-like, highly reflective surface—comparable to a polished finish but without mechanical abrasion.

- No need for post-annealing pickling.

- Preferred for decorative applications (e.g., appliance panels, architectural trim, medical instruments).

| Feature | 2B Finish | BA Finish |

|---|---|---|

| Reflectivity | Low to medium | High (mirror-like) |

| Surface Roughness (Ra) | ~0.1–0.3 µm | ~0.05–0.1 µm |

| Post-Processing Needed? | Sometimes (for enhanced shine) | Rarely |

| Cost | Lower | Higher (due to controlled atmosphere annealing) |

| Typical Use | Functional parts, hidden components | Visible surfaces, premium products |

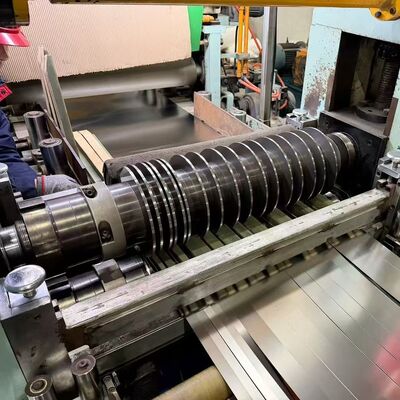

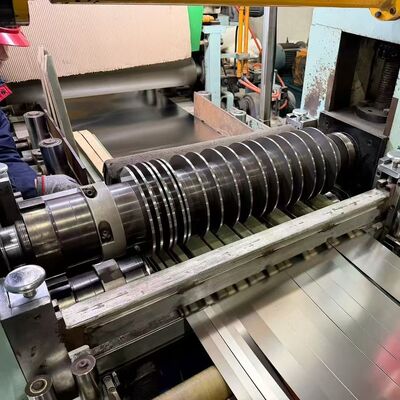

4. Precision Slitting Without Burrs: Why It Matters

Slitting is the process of cutting wide stainless steel coils into narrower strips of precise widths. Burr-free slitting is critical for several reasons:

- Assembly Efficiency: Burrs can interfere with automated feeding systems or cause jams in stamping presses.

- Safety: Sharp edges pose handling risks during manufacturing.

- Downstream Processing: Burrs compromise edge quality for welding, coating, or folding.

- Product Performance: In electronic or medical applications, even microscopic burrs can lead to failure.

Modern slitting lines use precision-ground circular knives, optimized overlap and clearance settings, and real-time monitoring to ensure clean, straight edges. Post-slitting edge conditioning (e.g., brushing or tumbling) may be applied for ultra-sensitive applications.

Typical Slitting Tolerances for 304 Strips:

- Width tolerance: ±0.05 mm to ±0.1 mm (depending on thickness and width)

- Edge camber: <0.1 mm per meter

- Burr height: <0.01 mm (often undetectable to touch)

5. Common Applications by Temper & Finish

| Application | Recommended Temper | Preferred Finish |

|---|---|---|

| Flexible hose reinforcement | Soft / 1/4H | 2B |

| Battery contact strips | 1/2H / 3/4H | BA |

| Watch bands & jewelry | FH | BA |

| Automotive sensor housings | 1/4H | 2B or BA |

| Medical scalpel blades | FH | BA (electropolished) |

| Spring clips | 3/4H / FH | 2B |

6. Quality Assurance & Standards

Reputable suppliers adhere to international standards such as:

- ASTM A666: Standard specification for annealed or cold-worked austenitic stainless steel sheet, strip, plate, and flat bar.

- JIS G4305: Japanese Industrial Standard for cold-rolled stainless steel strips.

- EN 10088-2: European standard for technical delivery conditions.

Certifications (e.g., ISO 9001, RoHS compliance) and mill test reports (MTRs) ensure traceability of chemical composition and mechanical properties.

Conclusion

304 stainless steel strips offer unmatched versatility through controlled tempers (Soft to FH), refined surface finishes (2B and BA), and precision slitting capabilities. Selecting the right combination depends on the application’s mechanical, aesthetic, and functional requirements. With advancements in metallurgy and processing technology, manufacturers can now deliver strips that meet the most demanding specifications—burr-free edges, tight tolerances, and consistent performance—making 304 stainless steel strips a cornerstone material in modern engineering and design.

![]()

![]()

![]()

![]()