-

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Bandes en acier inoxydable 304 souples 1/4H 1/2H 3/4H FH Bandes SS Surface 2B BA Coupe fendue sans bavure

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | TISCO |

| Certification | ISO |

| Numéro de modèle | 304 |

| Quantité de commande min | 2 tonnes |

| Prix | 1800 - 2500 USD/Ton |

| Détails d'emballage | Emballage standard pour l'exportation |

| Délai de livraison | 5 - 12 jours en fonction de la quantité |

| Conditions de paiement | LC, T/T, Western Union |

| Capacité d'approvisionnement | 20 tonnes par semaine |

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Produits | bande en acier inoxydable | Épaisseur | 0.1-3.0mm |

|---|---|---|---|

| largeur | Dans 1219 mm | Quantité minimale de commande | 20 kilogrammes |

| Grade | 200 séries 300 Série 300 | Surface | BA 2B n ° 4 HL 8K n ° 1 |

| Standard | Astm en gb jis | Emballage | Papier en bois et à l'épreuve de l'eau |

| Mettre en évidence | Bandes en acier inoxydable 304 à l'état recuit,Bandes en acier inoxydable surface 2B BA,Bandes en acier inoxydable coupées par refente sans bavure |

||

304 bandes d'acier inoxydable douces 1/4H 1/2H 3/4H FH SS bandes 2B BA Surface coupure par fente sans butée

| Produits | bande en acier inoxydable |

| Épaisseur | 0.1-3.0 mm |

| Largeur | largeur minimale de 5 mm |

| Nombre de pièces | 20 kgs |

| Grade majeur | Pour les appareils de traitement des eaux usées, le produit doit être soumis à un contrôle de qualité supérieur.2205,2507,904L,C276,400,600,625,926,825.etc. |

| Surface | Le montant de l'aide est fixé à la valeur de l'aide. |

| La norme | Pour les appareils de surveillance de la sécurité |

| Emballage | cadre en bois et papier étanche |

304 bandes en acier inoxydable: un guide complet sur les températures, les finitions de surface et la précision de découpe

Les bandes en acier inoxydable sont des composants essentiels dans un large éventail d'industries, de l'automobile et de l'aérospatiale à l'électronique, aux dispositifs médicaux et aux biens de consommation.L'acier inoxydable AISI 304 est l'un des types les plus utilisés.Lorsqu'il est transformé en bandes minces aux propriétés mécaniques et aux finitions de surface spécifiques, il est également utilisé pour la fabrication de produits chimiques.L'acier inoxydable 304 devient encore plus polyvalentCet article examine les caractéristiques clés des bandes en acier inoxydable 304 à différentes températures (soft, 1/4H, 1/2H, 3/4H, FH), finitions de surface courantes (2B et BA),et l'importance d'une découpe de précision sans bavures.

1. Vue d'ensemble de l'acier inoxydable 304

Le grade 304 (UNS S30400) est un acier inoxydable austénitique contenant environ 18% de chrome et 8% de nickel.

- Excellente résistance à l'oxydation et à la corrosion dans des environnements doux

- Bonne soudabilité et formabilité

- Propriétés non magnétiques dans l'état de recuit (peut devenir légèrement magnétique après traitement à froid)

- Haute ductilité et ténacité, même à température cryogénique

Ces caractéristiques le rendent idéal pour les applications de bande nécessitant à la fois l'intégrité structurelle et la qualité de la surface.

2Température mécanique: douce, 1/4H, 1/2H, 3/4H et FH

Les propriétés mécaniques des bandes en acier inoxydable sont adaptées par laminage à froid contrôlé, ce qui augmente la résistance tout en réduisant la ductilité.Le degré de travail à froid détermine la désignation de température:

| Température | Définition | Résistance à la traction typique (MPa) | Résistance au rendement (0,2% de décalage, MPa) | L'allongement (%) |

|---|---|---|---|---|

| D'une teneur en poids en poids en poids en poids | d'une épaisseur n'excédant pas 1 mm | 515 ¢ 620 | 205 minutes | ≥ 40 |

| 1 / 4 dur (1 / 4H) | Travail à froid léger; augmentation modérée de la résistance | 585 ¢ 725 | 275 ¢ 345 | 25 ¢ 35 |

| 1/2 dur (1/2H) | Travail à froid moyen; résistance et formabilité équilibrées | 725 ¢ 860 | 345 ¢ 450 | 15 ¢ 25 |

| 3/4, dur (3/4H) | Travaux à froid lourds; résistance élevée, formabilité limitée | 860 ¢ 1000 | 450 ¢ 550 | 8 ¢ 15 |

| Dureté totale (FH) | Travail à froid maximal; résistance très élevée, allongement minimal | ≥ 1000 | ≥ 550 | ≤ 8 |

Guide de mise en œuvre:

- Tempérament doux: Idéal pour les opérations de dessin, de pliage ou de formage complexes (par exemple, éviers de cuisine, garnitures automobiles).

- 1/4H et 1/2H: commun dans les ressorts, les supports et les contacts électriques où un retour modéré est acceptable.

- 3/4H & FH: Utilisé dans les ressorts plats, les composants snap-fit et les pièces résistantes à l'usure nécessitant une résistance élevée.

3- Finitions de surface: 2B contre brillant recuit (BA)

La finition de la surface a un impact significatif sur l'apparence, la résistance à la corrosion et l'adéquation aux processus secondaires tels que le placage ou la peinture.

2B Finition

- Il est obtenu par laminage à froid suivi d'un traitement thermique, d'un décapage et d'un laminage léger à travers la peau.

- Légère, semi-réfléchissante, apparence gris mat.

- Finition générale la plus courante.

- Convient pour les applications où l'esthétique est secondaire à la fonction (par exemple, équipement industriel, pièces structurelles).

Finition brillante recuit (BA)

- Produit par rechute dans une atmosphère contrôlée (hydrogène/azote) pour empêcher l'oxydation.

- Surface miroir, très réfléchissante, comparable à une finition polissée mais sans abrasion mécanique.

- Il n'y a pas besoin de décongeler après recuit.

- Préférée pour les applications décoratives (par exemple, panneaux d'appareils, garnitures architecturales, instruments médicaux).

| Caractéristique | 2B Finition | Finition BA |

|---|---|---|

| Réflectivité | Faible à moyen | Haute (à l'image d'un miroir) |

| Roughness de surface (Ra) | ~0,1 ∼0,3 μm | ~ 0,05 ‰ 0,1 μm |

| Un traitement ultérieur est- il nécessaire? | Parfois (pour une meilleure brillance) | Rarement |

| Coût | En bas | Plus élevé (en raison du recuit dans une atmosphère contrôlée) |

| Utilisation typique | Parties fonctionnelles, composants cachés | Surfaces visibles, produits haut de gamme |

4La découpe de précision sans bourreau: pourquoi cela compte

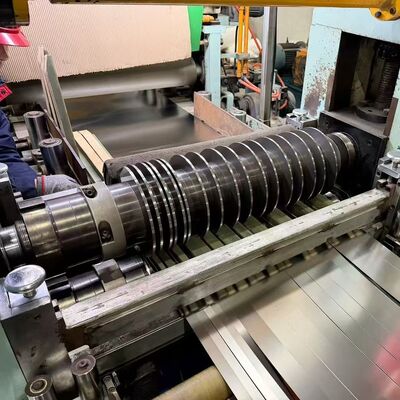

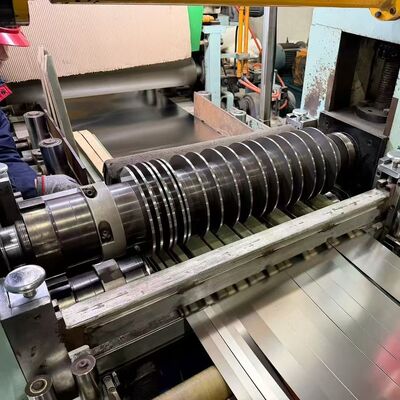

La découpe est le processus de découpe de larges bobines d'acier inoxydable en bandes plus étroites de largeurs précises.

- Efficacité d'assemblage: Les éboulements peuvent interférer avec les systèmes d'alimentation automatisés ou provoquer des embouteillages dans les presses d'estampage.

- Sécurité: les bords tranchants présentent des risques de manipulation pendant la fabrication.

- Traitement en aval: les éboulements compromettent la qualité des bords pour le soudage, le revêtement ou le pliage.

- Performance du produit: Dans les applications électroniques ou médicales, même des écailles microscopiques peuvent entraîner une défaillance.

Les lignes de découpe modernes utilisent des couteaux circulaires moulés de précision, des réglages de chevauchement et de dégagement optimisés et une surveillance en temps réel pour assurer des bords nets et droits.le brossage ou la chute) peut être appliqué pour des applications ultra sensibles.

Tolérances de coupure typiques pour 304 bandes:

- Tolérance de largeur: ±0,05 mm à ±0,1 mm (en fonction de l'épaisseur et de la largeur)

- Dépassement du bord: <0,1 mm par mètre

- Hauteur de la broche: < 0,01 mm (souvent indétectable au toucher)

5Applications courantes par température et finition

| Application du projet | Température recommandée | Finition préférée |

|---|---|---|

| Renforcement de tuyau flexible | Souple / 1/4H | 2B |

| Des bandes de contact pour batterie | 1/2H / 3/4H | Le titre |

| Montres et bijoux | FH | Le titre |

| Casques de capteurs automobiles | 1/4H | 2B ou BA |

| Blades de scalpel médical | FH | BA (électropolissé) |

| Des pinces à ressorts | 3/4H / FH | 2B |

6Assurance qualité et normes

Les fournisseurs réputés respectent les normes internationales telles que:

- ASTM A666: Spécification standard pour les tôles, bandes, plaques et barres plates d'acier inoxydable austénitique recuit ou travaillé à froid.

- JIS G4305: Norme industrielle japonaise pour les bandes en acier inoxydable laminées à froid.

- EN 10088-2: Norme européenne pour les conditions techniques de livraison.

Les certifications (par exemple, conformité ISO 9001 et RoHS) et les rapports d'essais d'usine assurent la traçabilité de la composition chimique et des propriétés mécaniques.

Conclusion

Les bandes en acier inoxydable 304 offrent une polyvalence inégalée grâce à des températures contrôlées (doux à FH), des finitions de surface raffinées (2B et BA) et des capacités de découpe de précision.La sélection de la bonne combinaison dépend de la mécaniqueAvec les progrès de la métallurgie et de la technologie de traitement, les fabricants peuvent désormais fournir des bandes qui répondent aux spécifications les plus exigeantestolérances serrées, et des performances constantes, la fabrication de bandes en acier inoxydable 304 est un matériau de base de l'ingénierie et du design modernes.

![]()

![]()

![]()

![]()