-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

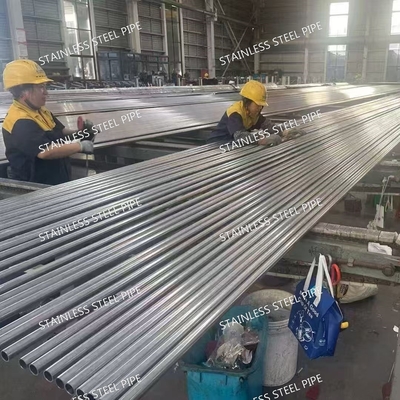

347H Stainless Steel Seamless Pipe ASTM A312 DN10-DN400

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Seamless Pipe | Grade | 347 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | 347H stainless steel seamless pipe,ASTM A312 stainless steel pipe,DN10-DN400 stainless steel pipe |

||

Alloy 347H Stainless Steel Tubing / ASTM A312 Austenitic Stainless Pipes TP347H for Industrial

Products Specification

| Products Name | 347 Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

Introduction of 347H Stainless Steel

I. Material Overview

347H (UNS S34709) is a niobium-stabilized austenitic stainless steel. By adding the niobium (Nb) element, it significantly enhances the resistance to intergranular corrosion, making it a core material for high-temperature and high-pressure environments. Its composition is based on chromium (17%-19%) and nickel (9%-13%), supplemented by niobium (≥10×C%), forming a stable niobium carbide (NbC) structure. This effectively prevents chromium carbides from precipitating at grain boundaries and avoids stress corrosion cracking. This material maintains organizational stability in the range of -196℃ to 850℃ and has both high strength and oxidation resistance, suitable for severe working conditions such as power station boilers and chemical reactors.

II. Core Performance Advantages

●

High-temperature mechanical properties

○

Strength and plasticity balance: At room temperature, the tensile strength is≥515 MPa, the yield strength is≥205 MPa, and the elongation is≥35%. At high temperatures of 600°C, the allowable stress remains above 100 MPa, which is better than conventional austenitic steels such as 304H in terms of creep resistance. The creep rupture strength is about 15% higher than that of 321H during long-term service at 550-700°C, suitable for supercritical power station steam pipes (design temperature 482°C/pressure 20.55 MPa).

●

Corrosion and oxidation resistance

○

Intergranular corrosion protection: The niobium element preferentially combines with carbon to suppress chromium depletion and resist corrosion by media such as nitric acid and acetic acid after welding or long-term heating below 650°C. High-temperature oxidation protection: The chromium oxide film is stable in air at 750-800°C, and the oxidation limit is 850°C (non-pressurized components), suitable for boiler superheater tubes.

●

Processing and welding performance

○

Cold and hot processing adaptability: Supports processes such as forging and rolling, but cold forming requires control of work hardening (multi-pass forming + intermediate annealing is recommended). Welding process optimization: It is recommended to use niobium-stabilized welding materials (such as ER347H) and use TGF-347 argon-free welding wire to improve efficiency. Thick-walled weldments require strict temperature control to avoid reheat cracking.

III. Key Heat Treatment Process

Heat treatment is a critical link to ensure the performance of 347H:

●

Solution treatment: Heat at 980-1150°C and then quickly cool to dissolve carbides and obtain a single austenite structure.

●

Stabilization treatment: For welded parts, keep at 890-910°C for insulation (constant temperature time≥50 hours) to promote the complete precipitation of NbC and eliminate residual stress. Note: Pipes with wall thicknesses greater than 37mm are prone to cracking due to thermal stress and require control of heating uniformity.

IV. Typical Application Fields

Field

Application scenario

Performance requirements

Power industry

Supercritical boiler superheater tubes (Φ51×8mm), reheater tubes, main steam pipes

High-temperature strength, oxidation resistance, and resistance to intergranular corrosion

Chemical industry

Chemical reactors and other equipment

Corrosion resistance to various media

...

347H stainless steel, with its excellent performance, is widely used in various fields and plays an important role in modern industrial production

![]()

![]()

![]()

![]()