-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

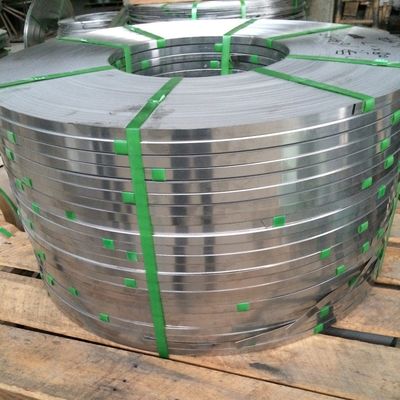

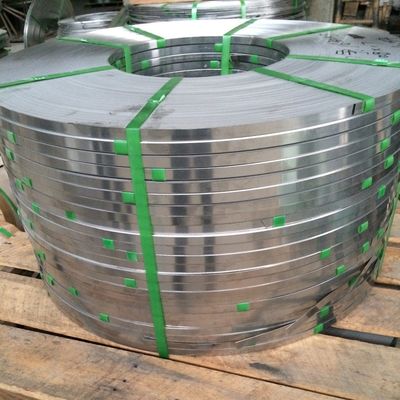

Cold Rolled Bright Stainless Steel Strip SS Strip Band 0.1 - 2.0mm Thickness Width 3 - 600mm

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 200Series 300 Series 400 Series C276 904L,Monel 400 |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.1 - 3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 200 Kgs |

| Grade | 200 Series 300 Series 400 Series , Nickel Alloy | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | thin stainless steel strips,stainless strip,stainless steel metal strips |

||

Cold Rolled Bright Stainless Steel Strip SS Strip Band 0.1 - 2.0mm Thickness Width 3 - 600mm

| Material | Nickel Alloy 800H,825,600,625,690,718 Hastelloy Alloy C276,C22 ,C2000, B2, B3, G30,Monel 400 K500 |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc |

| Technique | Hot rolled / Cold rolled |

| Thickness | 0.1mm-3.0mm or as required |

| Width | 5 - 1000mm as required |

| Type | Precisiion Strip |

| Surface Treatment | Bright annealiing , Cold Rolled 2B |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing |

| MOQ | 1000KG |

| Delivery time | 10-15 days |

| Export Packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

Monel 400 Alloy (UNS N04400)

Alloy 400 (UNS N04400) is a ductile nickel-copper alloy with resistance to a variety of corrosive conditions. The alloy is most frequently specified in environments ranging from mildly oxidizing through neutral and in moderately reducing conditions. An additional application area of the material is in marine environments and other nonoxidizing chloride solutions.

-------------------------------------------------------

General Properties

Alloy 400 (UNS N04400) is a ductile nickel-copper alloy with resistance to a variety of corrosive conditions. The alloy is most frequently specified in environments ranging from mildly oxidizing through neutral and in moderately reducing conditions. An additional application area of the material is in marine environments and other nonoxidizing chloride solutions.

The alloy has a long history of use as a corrosion resistant material, dating back to the early 20th century when it was developed as an attempt to use a high copper content nickel ore. The nickel and copper contents of the ore were in the approximate ratio which is now formally specified for the alloy.

As with commercially pure nickel, Alloy 400 is low in strength in the annealed condition. For this reason, a variety of tempers are used which have the effect of increasing the strength level of the material.

-------------------------------------------------------

Applications

Marine and chemical processing equipment

Valves, pumps, propeller shafts

Marine fixtures and fasteners

Gasoline and fresh water tanks

Process vessels and piping

Heat exchangers

-------------------------------------------------------

Standards

ASTM......................... B 127

ASME......................... SB 127

AMS ........................... 4544

Federal or Military...... QQ-N-281

-------------------------------------------------------

Corrosion Resistance

Alloy 400 is more corrosion resistant than commercially pure nickel (UNS N02200) under reducing conditions, and more resistant than refined copper alloys under oxidizing conditions.

In moderately reducing acids, neutral or alkaline solutions, Alloy 400 may be considered for use. The alloy is resistant to most alkalies, salts, organic substances, and atmospheric conditions. Alloy 400 is a consideration for cooler alkaline caustic conditions, although high temperature, high stress, and high concentrations of caustic have produced caustic stress corrosion cracking in the material. The alloy is used in reducing acids like sulfuric and hydrochloric, especially in the absence of aeration and oxidizing species.

Alloy 400 is exceptionally resistant to chloride stress corrosion cracking.

Application in waters, including sea and brackish water, is a major use of the material.

Alloy 400 is attacked in sulfur-bearing gases above approximately 700F (371C), and molten sulfur attacks the alloy at temperatures over approximately 500F (260C).

-------------------------------------------------------

Chemical Analysis

Typical Analysis (Weight %)

C Mn P S Si Al Ni + Co Cu Fe

0.10 0.50 0.005 0.005 0.25 0.02 Balance* 32.0 1.0

*By difference - For material furnished to QQ-N-281, lead, tin, and zinc are each typically <0.003.

-------------------------------------------------------

Mechanical Properties

The following are typical room temperature mechanical properties of Alloy 400. The lowest strength and most ductile condition is the annealed condition with typical properties as shown below.

Magnetic Permeability:

In the annealed condition the alloy is often moderately to faintly magnetic at room temperature. The Curie temperature of the material is close to room temperature. Above the Curie temperature, the material is nonmagnetic. The Curie temperature is influenced by minor composition variations, so some heats of material will be magnetic at room temperature and others will not.

-------------------------------------------------------

Heat Treatment

The anneal cycle conducted on Alloy 400 is typically in the 1400 to 1800F (760 to 980C) range for short times at temperature. The purpose is to soften the material after forming operations while maintaining a relatively fine grain size.

Annealing should be done in an atmosphere as free of sulfur compounds as possible since sulfur will embrittle the material in extended exposure time at the anneal temperature range.

A low temperature stress relief may be conducted on cold deformed material by heating to approximately 575F (300C) for 1 to 3 hours.

A large percentage of Alloy 400 is put into service without final heat treatment. This is done to increase the strength of the material.

-------------------------------------------------------

Processing

Cold Forming

Alloy 400 exhibits excellent cold forming characteristics normally associated with chromium nickel stainless steels. The alloy has a lower work hardening rate than Alloys 301 or 304 stainless steel and can be used in multiple draw forming operations where relatively large amounts of deformation occur between anneals.

-------------------------------------------------------

Welding

Alloy 400 may be joined by a variety of processes including gas tungsten-arc, gas metal-arc and shielded metal-arc processes. In all of these processes, thorough cleaning of the joint area is necessary to avoid embrittlement from such sources as lubricants and paints. The material must be free of scale for best welding.

![]()

![]()

![]()

![]()