-

Прокладка нержавеющей стали

-

Лист нержавеющей стали

-

Плита нержавеющей стали

-

труба нержавеющей стали

-

Адвокатура нержавеющей стали

-

Гальванизированная стальная катушка

-

Стальная пластина

-

стальной круглый бар

-

сплав никеля

-

Безшовная стальная труба

-

Луч нержавеющей стали

-

Лист медной плиты

-

Медная круглая Адвокатура

-

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

Raian IonescuМатериальное качество очень хорошее. мы имеем объединить больше чем 10 лет. Они торгуют видами серий стального материала. Полностью материальное качество хорошее. Они обязанность для полностью материального качества. Мы строгаем для того чтобы продолжать объединить с ними в будущем

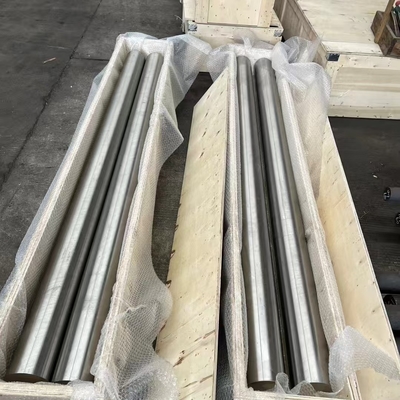

Ярко полированный круглый пруток из никелевого сплава Inconel 625 / Круглый стальной пруток по стандартам EN ASTM GB JIS

| Место происхождения | КИТАЙ |

|---|---|

| Фирменное наименование | DELTA |

| Сертификация | ISO |

| Номер модели | UNS N06625 / 625 / 2,4856 |

| Количество мин заказа | 500 кг |

| Цена | 30 - 35 USD/Kg |

| Упаковывая детали | стандартная упаковка для экспорта |

| Время доставки | 5 - 12 дней на основе количества |

| Условия оплаты | L/C, T/T, Western Union |

| Поставка способности | 3 тонны в неделю |

Свяжитесь я бесплатно образцы и талоны.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Если вы имеете любую заботу, то мы предусматриваем 24-часовую интерактивную справку.

x| Продукция | Плита из никелевого сплава | Оценка | UNS N06625 / 625 |

|---|---|---|---|

| Диаметр | 6 - 350 мм | Длина | настройка резки любой длины по запросу |

| Стандартный | Astm en | Услуга | Резка |

| Загрузочный порт | Шанхайский порт | Поверхность | чёрный, яркий |

| Выделить | Круглый стержень из никелевого сплава Inconel 625,Ярко отполированные стальные слитки никеля,EN ASTM стандартная никелевая стержня |

||

Ярко отполированный инконель 625 из никелевого сплава круглый ствол / круглый стальной ствол EN ASTM GB JIS Standard

Более подробная информация

| Наименование продукции | НС ООН N06625 Круглый прут из никелевого сплава |

| Диаметр | 6.0 - 350 мм |

| Длина | настройка резки любой длины по запросу |

| Поверхность | Черный, яркий |

| Бренд | ДЕЛТА |

| Служба | резка, полировка |

| МОК | 2 кг |

| Другие виды | Круглый стержень, лента, катушка, труба, лист, пластина, проволока и т.д. |

| Упаковка | водонепроницаемая бумага и деревянные поддоны, деревянная коробка |

| Порт погрузки | Шанхайский порт |

| Срок цены | EXW, FOB, CIF, CFR |

| Время доставки | в течение 12 дней |

Регулярный диаметр Inconel 625 Round Bar на складе

| 6 мм | 8 мм | 9 мм | 10 мм | 12 мм | 14 мм |

| 15 мм | 16 мм | 18 мм | 19 мм | 20 мм | 22 мм |

| 25 мм | 28 мм | 30 мм | 32 мм | 35 мм | 38 мм |

| 40 мм | 42 мм | 45 мм | 48 мм | 50 мм | 55 мм |

| 60 мм | 65 мм | 70 мм | 75 мм | 80 мм | 85 мм |

| 90 мм | 95 мм | 100 мм | 105 мм | 110 мм | 115 мм |

| 120 мм | 125 мм | 130 мм | 140 мм | 150 мм | 160 мм |

| 170 мм | 180 мм | 190 мм | 200 мм | 210 мм | 220 мм |

| 230 мм | 240 мм | 250 мм | 260 мм | 270 мм | 280 мм |

| 290 мм | 300 мм | 310 мм | 320 мм | 330 мм | 340 мм |

Ярко отполированный инконель 625 из никелевого сплава круглый ствол / круглый стальной ствол EN ASTM GB JIS Standard

Обзор продукции

Наши ярко отполированные круглые штанги Inconel 625 представляют собой вершину коррозионно-устойчивых штанг из никелевого сплава, разработанных для исключительных характеристик в самых требовательных условиях.,сверхсплав никель-хром-молибден-ниобий, известный своей уникальной комбинацией высокой прочности, отличной изготовляемости и исключительной стойкости к широкому спектру коррозионных сред,окислениеЯркая полированная отделка обеспечивает превосходное качество поверхности, что обеспечивает высокую точность измерений, повышенную эстетическую привлекательность,и уменьшение потребности в дополнительной отделке, что делает его идеальным выбором для высокоточной обработки и критических приложений в аэрокосмической, морской, химической и энергетической отраслях.Этот продукт производится и поставляется в полном соответствии с основными международными стандартами., включая ASTM, EN (европейский стандарт), GB (китайский Guobiao) и JIS (японские промышленные стандарты), гарантирующие глобальное качество и согласованность.

Ключевые характеристики и преимущества

-

Исключительная коррозионная стойкость: отличная устойчивость к рву, коррозии трещин и коррозионному трещину при напряжении.и соленой атмосферы, устойчивы к атакам хлоридов и окислительных химических веществ.

-

Высокая прочность при высоких температурах: механизм укрепления, обеспечиваемый ниобием (в сочетании с молибденом), дает сплаву высокую прочность, прочность на растяжение и прочность на разрыв.свойства, которые сохраняются при криогенных температурах до приблизительно 1000°C (1800°F).

-

Высокая устойчивость к окислению: образует устойчивый, сцепляющийся слой оксида, который обеспечивает отличную защиту от окисления и карбуризации в условиях высокой температуры.

-

Отличная изготовляемость: несмотря на свою высокую прочность, Inconel 625 может быть легко сварен и изготовлен с использованием обычных методов без послесварной термической обработки для поддержания коррозионной стойкости.

-

Яркая полированная отделка: холодный процесс рисования и полирования приводит к гладкой, почти зеркальной отделке поверхности.улучшает коррозионную стойкость путем устранения поверхностных недостатков, и обеспечивает отличную подложку для дальнейшей обработки или для использования в визуально критических компонентах.

Стандартные спецификации и эквивалентные классы

| Стандартный | Степень/назначение | Спецификация формы продукта |

|---|---|---|

| ASTM | НС ООН N06625 | ASTM B446 (бесшовные прутки и проволоки) |

| EN (Европейский стандарт) | NiCr22Mo9Nb | EN 2.4856 (номер материала) |

| GB (Китай) | NS3306 | GB/T 15008 (бар) |

| JIS (Япония) | NCF625 | JIS G4902 (резистентная к теплу штанга) |

Подробный химический состав (в массовых %)

| Элемент | Ни. | КР | Мо | Nb (+Ta) | Фэ | В | Мн | Да, да. | Аль. | Ти | П | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Минуточку. | 58.0 | 20.0 | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Макс. Макс. | - | 23.0 | 10.0 | 4.15 | 5.0 | 0.10 | 0.50 | 0.50 | 0.40 | 0.40 | 0.015 | 0.015 |

Типичные механические свойства (при комнатной температуре)

-

Прочность на растяжение: ≥ 830 MPa (120 ksi)

-

Устойчивость к выходу (0,2% смещения): ≥ 415 МПа (60 кси)

-

Удлинение: ≥ 30%

-

Твердость: обычно ≤ 90 HRB

Доступные спецификации

-

Форма: Круглые прутки (твердые)

-

Диаметр диапазона: от 6 мм (0,236 дюйма) до 300 мм (11,81 дюйма) - наличие конкретного размера может варьироваться.

-

Длина: стандартные случайные длины мельницы или индивидуальные варианты резки по длине.

-

Состояние: раствор прожектованный / ярко отполированный (холодный и отполированный)

-

Толерантность: поставляется с узкими допустимыми размерами в соответствии с требованиями ASTM или конкретных требований заказчика.

Производственный процесс и обеспечение качества

Our Bright Polished Inconel 625 bars are produced through a rigorously controlled process involving vacuum induction melting (VIM) and/or electric arc melting followed by secondary refining processes like ESR (Electro-Slag Remelting) to ensure extreme purity and homogeneityЗатем слитки нагревают, разбавляют раствором, чтобы оптимизировать микроструктуру, и, наконец, протягивают холодом и полируют, чтобы достичь яркой, гладкой отделки.Каждая партия подтверждается сертификатом испытаний на мельнице (MTC), соответствующим EN 10204 3.1 или эквивалентный, обеспечивающий полную прослеживаемость и проверку химического состава и механических свойств в соответствии с заказанным стандартом.

Заявления

Этот высокопроизводительный сплав специфицируется для критических компонентов, где отказ не является вариантом.

-

Аэрокосмическая промышленность: реверсоры тяги двигателя, выхлопные системы, каналы, кольца и корпуса.

-

Морские и оффшорные: лопасти пропеллеров, компоненты подводных лодок, трубы морской воды, теплообменники на судах и оффшорных платформах.

-

Химическая обработка: реакторы, сосуды, колонны, трубы для теплообменников, трубопроводы для агрессивной химической среды.

-

Нефть и газ: инструменты для добычи леса, компоненты скважин, системы разделения газа, коллекторы для подавления и уничтожения.

-

Контроль за загрязнением: Скраберы, стекольные облицовки, амортизаторы и вентиляторы в системах десульфуризации дымовых газов (FGD).

-

Ядерная энергетика: основные компоненты, механизмы управления и трубопроводы системы очистки воды реактора.

Почему выбирать наш продукт?

Мы специализированный поставщик высокопроизводительных никелевых сплавов, стремящийся предоставить не только материалы, но и всеобъемлющую техническую поддержку.и опыт в международных стандартах гарантируют, что вы получите продукт, который отвечает вашим точным инженерным требованиям, поддерживаемый надежным сервисом и глобальной логистической поддержкой.

![]()

![]()

![]()

![]()