-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

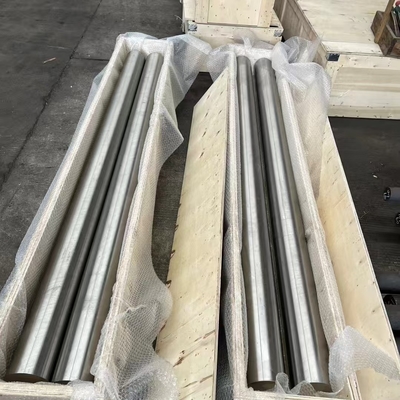

밝게 닦은 인코넬 625 니켈 합금 둥근 막대 / 둥근 강철 막대 EN ASTM GB JIS 표준

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 제품 | 니켈 합금판 | 등급 | UNS N06625 / 625 |

|---|---|---|---|

| 지름 | 6-350mm | 길이 | 요청에 따라 모든 길이를 커스터마 절단합니다 |

| 기준 | astm en | 서비스 | 절단 |

| 로딩 포트 | 상하이 항구 | 표면 | 검은색, 밝은 |

| 강조하다 | 인코넬 625 니켈 합금 둥근 막대,밝게 닦은 니켈 합금 강철 막,EN ASTM 표준 니켈 합금 막대 |

||

밝게 닦은 인코넬 625 니켈 합금 둥근 막대 / 둥근 강철 막대 EN ASTM GB JIS 표준

더 많은 사양 정보

| 제품 이름 | UNS N06625 니켈 합금 둥근 막대 |

| 직경 | 60.0~350mm |

| 길이 | 주문에 따라 모든 길이의 절단 |

| 표면 | 검은색, 밝은 |

| 브랜드 | 델타 |

| 서비스 | 절단, 닦기 |

| MOQ | 2kg |

| 다른 종류 | 둥근 막대, 스트립, 코일, 파이프, 시트, 플레이트, 와이어 등 |

| 포장 | 방수용 종이와 목재 팔렛, 목재 상자 |

| 로딩 포트 | 상하이 항구 |

| 가격 기간 | EXW,FOB,CIF,CFR |

| 배달 시간 | 12일 이내에 |

인코넬 625 둥근 바의 정규 지름

| 6mm | 8mm | 9mm | 10mm | 12mm | 14mm |

| 15mm | 16mm | 18mm | 19mm | 20mm | 22mm |

| 25mm | 28mm | 30mm | 32mm | 35mm | 38mm |

| 40mm | 42mm | 45mm | 48mm | 50mm | 55mm |

| 60mm | 65mm | 70mm | 75mm | 80mm | 85mm |

| 90mm | 95mm | 100mm | 105mm | 110mm | 115mm |

| 120mm | 125mm | 130mm | 140mm | 150mm | 160mm |

| 170mm | 180mm | 190mm | 200mm | 210mm | 220mm |

| 230mm | 240mm | 250mm | 260mm | 270mm | 280mm |

| 290mm | 300mm | 310mm | 320mm | 330mm | 340mm |

밝게 닦은 인코넬 625 니켈 합금 둥근 막대 / 둥근 강철 막대 EN ASTM GB JIS 표준

제품 개요

우리의 밝게 닦은 인코넬 625 둥근 바는 가장 까다로운 환경에서 예외적인 성능을 위해 설계된,니켈-크롬-몰리브덴-니오비움 초연금으로, 고강도, 우수한 제조성, 그리고 광범위한 부식 매체에 대한 뛰어난 저항성의 독특한 조합으로 유명합니다.산화, 고온. 밝은 닦은 (냉면 당겨 닦은) 완성도는 가까운 차원 정확성, 향상 된 미적 호소,그리고 추가 가공의 필요성을 줄입니다., 정밀 가공 및 항공 우주, 해양, 화학 처리 및 에너지 분야에서 중요한 응용 분야에 이상적인 선택입니다.이 제품은 주요 국제 표준을 완전히 준수하여 제조 및 공급됩니다., ASTM, EN (유럽 표준), GB (중국 Guobiao) 및 JIS (일본 산업 표준) 를 포함하여 글로벌 품질과 일관성을 보장합니다.

주요 특징 및 이점

-

탁월한 경식 저항성: 틈, 균열 경식, 스트레스 경식 균열에 탁월한 저항을 제공합니다. 그것은 산성 환경, 바닷물,그리고 소금성 대기, 염화물질과 산화 화학 물질의 공격에 저항합니다.

-

온도 상에서의 높은 강도: 니오비아 (몰리브덴과 결합) 이 제공하는 강화 메커니즘은 합금에 높은 출력, 팽창력 및 미끄러짐 깨지기 강도를 제공합니다.약 1000°C (1800°F) 까지의 냉동 온도에서 유지되는 성질.

-

우수한 산화 저항: 고온 서비스 조건에서 산화 및 탄화화로부터 우수한 보호를 제공하는 안정적이고 끈적 인 산화층을 형성합니다.

-

우수한 제조성: 높은 강도에도 불구하고 인코넬 625은 부식 저항성을 유지하기 위해 용접 후 열 처리가 필요없이 일반적인 기술을 사용하여 쉽게 용접되고 제조 될 수 있습니다.

-

밝게 닦은 가공: 냉면 도출 및 닦기 과정 은 부드럽고 거의 거울 같은 표면 가공 을 가져옵니다. 이것은 마찰 을 줄이고 표면 오염 을 최소화 합니다.표면 불완전성을 제거하여 부식 저항성을 향상시킵니다., 그리고 추가 가공 또는 시각적으로 중요한 구성 요소에 사용할 수있는 훌륭한 기판을 제공합니다.

표준 사양 및 동등 한 등급

| 표준 | 등급/명칭 | 제품 형태 사양 |

|---|---|---|

| ASTM | UNS N06625 | ASTM B446 (고름 없는 막대 및 와이어) |

| EN (유럽 표준) | NiCr22Mo9Nb | EN 2.4856 (물질 번호) |

| GB (중국) | NS3306 | GB/T 15008 (바르) |

| JIS (일본) | NCF625 | JIS G4902 (열에 저항하는 바) |

상세한 화학 성분 (중 %)

| 원소 | 니 | Cr | 모 | Nb (+Ta) | 페 | C | 원 | 네 | 알 | 티 | P | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 미네 | 58.0 | 20.0 | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| 맥스 | - | 23.0 | 10.0 | 4.15 | 5.0 | 0.10 | 0.50 | 0.50 | 0.40 | 0.40 | 0.015 | 0.015 |

전형적인 기계적 특성 (실온)

-

팽창 강도: ≥ 830 MPa (120 ksi)

-

내력 강도 (0.2% 오프셋): ≥ 415 MPa (60 ksi)

-

연장: ≥ 30%

-

강도: 일반적으로 ≤ 90 HRB

사용 가능한 사양

-

형태: 둥근 막대 (고체)

-

지름 범위: 6 mm (0.236 인치) ~ 300 mm (11.81 인치) - 특정 크기의 가용성은 다를 수 있습니다.

-

길이: 표준 무작위 밀링 길이 또는 사용자 정의 절단 길이 옵션.

-

상태: 용액 가열 / 밝게 닦은 (냉면 당겨 닦은)

-

용도: ASTM 또는 고객 특수한 요구 사항에 따라 엄격한 차원 용량으로 공급됩니다.

제조 과정 및 품질 보장

Our Bright Polished Inconel 625 bars are produced through a rigorously controlled process involving vacuum induction melting (VIM) and/or electric arc melting followed by secondary refining processes like ESR (Electro-Slag Remelting) to ensure extreme purity and homogeneity그 다음 막대기는 뜨겁게 가공되고, 미세 구조를 최적화하기 위해 용액으로 연금되고, 마침내 밝고 부드러운 완성도를 얻기 위해 냉면 당겨 닦습니다.각 팩은 EN 10204 3에 따라 밀링 테스트 인증서 (MTC) 를 지원합니다..1 또는 이에 해당하는 표준에 따라 화학적 성분과 기계적 특성을 완전히 추적하고 검증할 수 있도록 한다.

신청서

이 고성능 합금은 실패가 옵션이 아닌 중요한 구성 요소에 대해 지정됩니다. 대표적인 응용 분야는 다음과 같습니다.

-

항공우주: 엔진 추진력 역전기, 배기 시스템, 운수관, 고리 및 껍질.

-

해양 및 해상: 선박 및 해상 플랫폼의 프로펠러 블레이드, 잠수함 부품, 바닷물 파이프, 열 교환기.

-

화학 처리: 반응기, 용기, 기둥, 열 교환기 파이프, 공격적인 화학 환경을 위한 파이프 시스템.

-

오일 & 가스: 하구 로깅 도구, 우물 머리 부품, 가스 분리 시스템, 질식 및 킬 조리장.

-

오염 조절: 연소 가스 탈황화 (FGD) 시스템 내의 스크러버, 스택 라인러, 덤퍼 및 팬.

-

원자력: 핵심 부품, 제어 바드 메커니즘, 원자로 물 정화 시스템 파이프.

왜 우리 제품을 선택합니까?

우리는 고성능 니켈 합금의 전문 공급자입니다.그리고 국제 표준에 대한 전문 지식은 당신이 당신의 정확한 엔지니어링 요구 사항을 충족하는 제품을받을 수 있도록 보장합니다., 신뢰할 수 있는 서비스와 글로벌 물류 지원에 의해 뒷받침됩니다.

![]()

![]()

![]()

![]()