-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

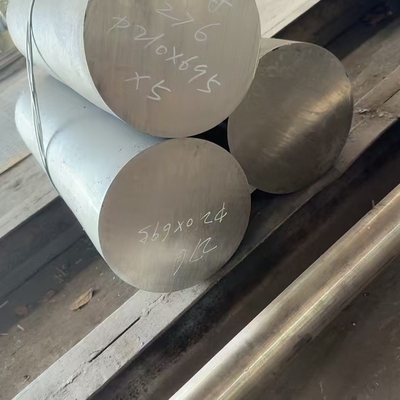

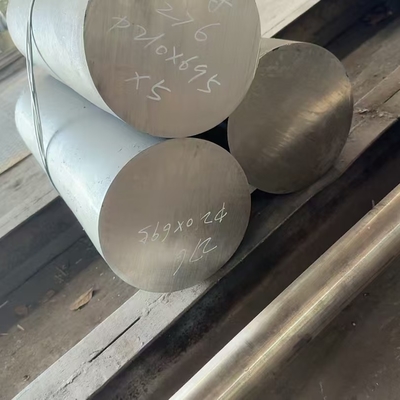

Barra tonda in lega di nichel UNS N06625 Diametro 6 - 350mm Barre laminate a caldo / Barre lucide

| Luogo di origine | Cina |

|---|---|

| Marca | DELTA |

| Certificazione | ISO |

| Numero di modello | UNS N06625 / 625 |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 30 - 35 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 3 tonnellate a settimana |

Contattimi gratis campioni e buoni.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se avete di preoccupazione, forniamo la guida in linea di 24 ore.

x| Prodotti | Placca in lega di nichel | Grado | UNS N06625 / 625 |

|---|---|---|---|

| Diametro | 6 - 350 mm | Lunghezza | taglio su misura di qualsiasi lunghezza su richiesta |

| Standard | Astm en | Servizio | Taglio |

| Porta di caricamento | Shanghai Port | Superficie | nero, luminoso |

| Evidenziare | N06625 barre rotonde di lega di nichel,Barre di lega di nichel laminate a caldo,barrette lucide di lega di nichel 6-350 mm |

||

Barra tonda in lega di nichel UNS N06625 Diametro 6 - 350mm Barre laminate a caldo / Barre lucide

Maggiori informazioni sulle specifiche

| Nome dei prodotti | Barra tonda / Asta in lega di nichel UNS N06625 |

| Diametro | 6.0 - 350mm |

| Lunghezza | taglio personalizzato di qualsiasi lunghezza su richiesta |

| Superficie | Nero, lucido |

| Marchio | DELTA |

| Servizio | taglio, lucidatura |

| MOQ | 2 Kg |

| Altro tipo | barra tonda, striscia, bobina, tubo, lamiera, piastra, filo, ecc. |

| Imballaggio | carta impermeabile e pallet di legno, scatola di legno |

| Porto di carico | Porto di Shanghai |

| Termine di prezzo | EXW, FOB, CIF, CFR |

| Tempi di consegna | entro 12 giorni |

Diametro regolare della barra tonda in Inconel 625 a magazzino

| 6mm | 8mm | 9mm | 10mm | 12mm | 14mm |

| 15mm | 16mm | 18mm | 19mm | 20mm | 22mm |

| 25mm | 28mm | 30mm | 32mm | 35mm | 38mm |

| 40mm | 42mm | 45mm | 48mm | 50mm | 55mm |

| 60mm | 65mm | 70mm | 75mm | 80mm | 85mm |

| 90mm | 95mm | 100mm | 105mm | 110mm | 115mm |

| 120mm | 125mm | 130mm | 140mm | 150mm | 160mm |

| 170mm | 180mm | 190mm | 200mm | 210mm | 220mm |

| 230mm | 240mm | 250mm | 260mm | 270mm | 280mm |

| 290mm | 300mm | 310mm | 320mm | 330mm | 340mm |

Barra tonda in lega di nichel UNS N06625 Diametro 6 - 350mm Barre laminate a caldo / Barre lucide

1. Parametri di base

| Categoria di parametri | Dettagli |

|---|---|

| Designazione della lega | UNS N06625, Werkstoff n. 2.4856, ASTM B446 (primario per barre tonde) |

| Gamma di diametri | 6 mm – 350 mm (copre piccole barre di precisione e grandi barre strutturali) |

| Finitura superficiale | - Barre laminate a caldo: superficie opaca, leggermente ruvida (Ra 6,3–12,5 µm), adatta per la lavorazione meccanica o l'ulteriore lavorazione. - Barre lucide: superficie lucida/liscia (Ra 0,8–3,2 µm), ideale per applicazioni che richiedono prestazioni estetiche o a basso attrito. |

| Lunghezza | Standard: 2–6 metri (lunghezze personalizzate disponibili su richiesta) |

| Trattamento termico | Tipico: ricottura di soluzione a 980–1150°C (1800–2100°F), seguita da tempra rapida (raffreddamento ad acqua o ad aria) per ottimizzare la resistenza alla corrosione e la duttilità. |

| Composizione chimica | Nichel (Ni): ≥58%; Cromo (Cr): 20–23%; Molibdeno (Mo): 8–10%; Niobio (Nb) + Tantalio (Ta): 3,15–4,15%; Ferro (Fe): ≤5%; Carbonio (C): ≤0,10%; Manganese (Mn): ≤0,50%; Silicio (Si): ≤0,50%; Fosforo (P): ≤0,015%; Zolfo (S): ≤0,015%. |

2. Proprietà meccaniche e fisiche

2.1 Proprietà meccaniche (dopo ricottura di soluzione)

| Proprietà | Valore (tipico) | Standard di prova |

|---|---|---|

| Resistenza alla trazione | ≥827 MPa (120 ksi) | ASTM E8 |

| Limite di snervamento (0,2% di offset) | ≥414 MPa (60 ksi) | ASTM E8 |

| Allungamento (in 50 mm) | ≥30% | ASTM E8 |

| Durezza (Brinell) | ≤248 HB | ASTM E10 |

| Resistenza all'urto (Charpy V-Notch, 20°C) | ≥100 J (74 ft-lb) | ASTM E23 |

2.2 Proprietà fisiche

| Proprietà | Valore (a 20°C se non diversamente indicato) |

|---|---|

| Densità | 8,44 g/cm³ (0,305 lb/in³) |

| Conducibilità termica | 11,8 W/(m·K) (82 Btu·in/(ft²·h·°F)) |

| Coefficiente di espansione termica (20–100°C) | 12,8 × 10⁻⁶/°C (7,1 × 10⁻⁶/°F) |

| Resistività elettrica | 1,29 × 10⁻⁶ Ω·m (771 Ω·cir-mil/ft) |

| Intervallo di fusione | 1290–1350°C (2350–2460°F) |

3. Standard di produzione e qualità

| Tipo di standard | Standard pertinenti |

|---|---|

| Standard dei materiali | - ASTM B446: Specifiche standard per barre, aste e fili in lega di nichel-cromo-molibdeno-columbio (UNS N06625) - ASME SB446: Approvazione del codice per caldaie e recipienti a pressione (BPVC) per componenti contenenti pressione - DIN EN 10269: Standard europeo per barre in lega di nichel - JIS H4552: Standard industriale giapponese per barre in lega di nichel-cromo-molibdeno |

| Standard dimensionali | - ASTM B880: Specifiche standard per i requisiti generali per barre e aste in nichel e leghe di nichel - ISO 10288: Standard internazionale per le tolleranze dimensionali delle barre metalliche |

| Standard di prova | - ASTM E8 (prove di trazione), ASTM E23 (prove di impatto), ASTM E10 (prove di durezza) - ASTM A262 (prove di corrosione intergranulare) - NACE MR0175/ISO 15156: Per servizi acidi (applicazioni petrolifere/del gas) |

4. Gradi equivalenti

| Regione | Designazione del grado equivalente |

|---|---|

| Stati Uniti | UNS N06625, ASTM B446 (Inconel 625) |

| Europa | Werkstoff n. 2.4856, DIN EN 10269 |

| Giappone | JIS H4552 (NCF625) |

| Cina | GB/T 15007 (N06625) |

| Internazionale (ISO) | ISO 6363-3 (NiCr22Mo9Nb) |

5. Caratteristiche principali

- Eccezionale resistenza alla corrosione: resiste alla corrosione uniforme, alla vaiolatura, alla corrosione interstiziale e alla tensocorrosione (SCC) in mezzi aggressivi, tra cui acqua di mare, soluzioni acide (ad es. acido solforico, acido cloridrico) e ambienti ricchi di cloruri. Ciò è attribuito al suo elevato contenuto di cromo e molibdeno, oltre alla stabilizzazione del niobio.

- Prestazioni ad alta temperatura: mantiene la resistenza meccanica e la resistenza all'ossidazione a temperature fino a 1093°C (2000°F), senza significative deformazioni da creep sotto stress termico a lungo termine.

- Eccellente fabbricabilità: le barre laminate a caldo sono facili da lavorare, forgiare o saldare (con metalli d'apporto adeguati come ERNiCrMo-3); le barre lucide richiedono una post-elaborazione minima per applicazioni di precisione.

- Microstruttura stabile: il niobio forma fasi intermetalliche (ad es. precipitati γ'') che rafforzano la lega senza compromettere la duttilità, evitando fasi fragili anche dopo una prolungata esposizione ad alte temperature.

6. Applicazioni

- Petrolio e gas: tubi di perforazione, componenti di testa di pozzo e valvole per servizi acidi (alto H₂S/CO₂);condotte sottomarine e connettori (resistenti alla corrosione dell'acqua di mare).

- Aerospaziale e aviazione: pale di turbina, camere di combustione e sistemi di scarico (resiste alle alte temperature e ai cicli termici);elementi di fissaggio e parti strutturali per motori aeronautici.

- Processi chimici: reattori, scambiatori di calore e alberi di pompe (resiste a sostanze chimiche corrosive come acidi, alcali e solventi organici).

- Generazione di energia: tubi di caldaia, componenti di turbine a vapore e parti interne di reattori nucleari (tollerano alta pressione e stress termico).

- Ingegneria navale: alberi di elica, componenti dello scafo della nave e strutture di piattaforme offshore (immuni alla vaiolatura dell'acqua di mare e all'incrostazione biologica).

- Apparecchiature mediche: strumenti chirurgici e dispositivi impiantabili (biocompatibili e resistenti alla corrosione nei fluidi corporei).

![]()

![]()

![]()

![]()