모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

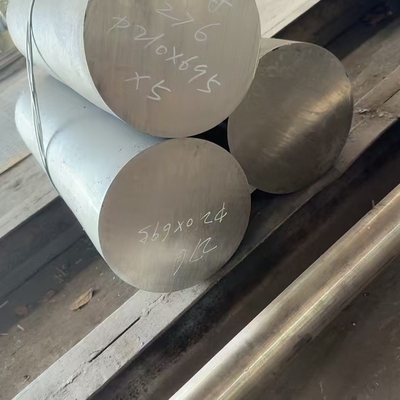

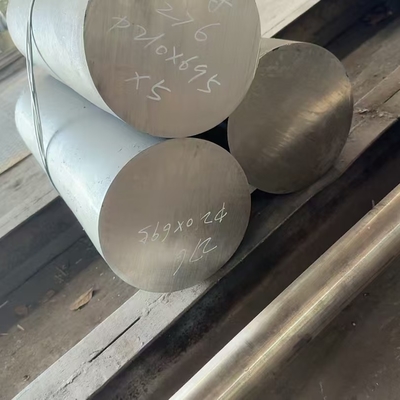

UNS N06625 니켈 합금 둥근 막대 지름 6 - 350mm 뜨거운 롤링 막대 / 밝은 막대

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x제품 상세 정보

| 제품 | 니켈 합금판 | 등급 | UNS N06625 / 625 |

|---|---|---|---|

| 지름 | 6-350mm | 길이 | 요청에 따라 모든 길이를 커스터마 절단합니다 |

| 기준 | astm en | 서비스 | 절단 |

| 로딩 포트 | 상하이 항구 | 표면 | 검은색, 밝은 |

| 강조하다 | UNS N06625 니켈 합금 환봉,고온으로 롤드 된 니켈 합금 막,밝은 봉 니켈 합금 6-350mm |

||

제품 설명

UNS N06625 니켈 합금 둥근 막대 지름 6 - 350mm 뜨거운 롤링 막대 / 밝은 막대

더 많은 사양 정보

| 제품 이름 | UNS N06625 니켈 합금 둥근 막대 |

| 직경 | 60.0~350mm |

| 길이 | 주문에 따라 모든 길이의 절단 |

| 표면 | 검은색, 밝은 |

| 브랜드 | 델타 |

| 서비스 | 절단, 닦기 |

| MOQ | 2kg |

| 다른 종류 | 둥근 막대, 스트립, 코일, 파이프, 시트, 플레이트, 와이어 등 |

| 포장 | 방수용 종이와 목재 팔렛, 목재 상자 |

| 로딩 포트 | 상하이 항구 |

| 가격 기간 | EXW,FOB,CIF,CFR |

| 배달 시간 | 12일 이내에 |

인코넬 625 둥근 바의 정규 지름

| 6mm | 8mm | 9mm | 10mm | 12mm | 14mm |

| 15mm | 16mm | 18mm | 19mm | 20mm | 22mm |

| 25mm | 28mm | 30mm | 32mm | 35mm | 38mm |

| 40mm | 42mm | 45mm | 48mm | 50mm | 55mm |

| 60mm | 65mm | 70mm | 75mm | 80mm | 85mm |

| 90mm | 95mm | 100mm | 105mm | 110mm | 115mm |

| 120mm | 125mm | 130mm | 140mm | 150mm | 160mm |

| 170mm | 180mm | 190mm | 200mm | 210mm | 220mm |

| 230mm | 240mm | 250mm | 260mm | 270mm | 280mm |

| 290mm | 300mm | 310mm | 320mm | 330mm | 340mm |

UNS N06625 니켈 합금 둥근 막대 지름 6 - 350mm 뜨거운 롤링 막대 / 밝은 막대

인코넬 625 (UNS N06625로 지정된) 는 뛰어난 진식 저항력, 고온 강도,그리고 구조적 안정성 때문에 그 둥근 막대는 까다로운 산업용 용도에 필수 요소가 됩니다아래는 그 매개 변수, 성질, 표준, 동등 한 등급, 주요 기능 및 일반적인 사용에 대한 포괄적 인 개요입니다.핫 롤링 및 밝은 막대기의 6~350mm 지름 범위에 초점을 맞추고.

1기본 매개 변수

여기서 언급되는 UNS N06625 둥근 막대 (Inconel 625) 는 엄격한 차원 및 재료 사양을 준수하며 주요 매개 변수는 다음과 같습니다.

| 매개 변수 범주 | 세부 사항 |

|---|---|

| 합금 명칭 | UNS N06625, Werkstoff No. 24856, ASTM B446 (둥근 막대기용) |

| 지름 범위 | 6mm 350mm (작은 정밀 막대에서 큰 구조 막대까지 포함됩니다) |

| 표면 마감 | - 뜨거운 롤링 바: 매트, 약간 거친 표면 (Ra 6.3~12.5μm), 가공 또는 추가 가공에 적합합니다. - 밝은 바: 닦은 / 부드러운 표면 (Ra 0.8 ~ 3.2μm), 미적 또는 낮은 마찰 성능을 요구하는 응용 프로그램에 이상적입니다. |

| 길이 | 표준: 2~6m (요청에 따라 사용자 정의 길이 제공) |

| 열처리 | 전형적: 980~1150°C (1800~2100°F) 에서 용액 응열, 그 다음 급속한 진압 (물 또는 공기 냉각) 으로 진열 저항성과 유연성을 최적화합니다. |

| 화학적 성분 | 니켈 (Ni): ≥58%; 크롬 (Cr): 20~23%; 몰리브덴 (Mo): 8~10%; 니오비아 (Nb) + 탄탈 (Ta): 3.15~4.15%; 철 (Fe): ≤5%; 탄소 (C): ≤0.10%; 망간 (Mn): ≤0.50%; 실리콘 (Si): ≤0.50%포스포스 (P): ≤0.015%; 황 (S): ≤0.015% |

2기계적 및 물리적 특성

인코넬 625 둥근 막대기는 뛰어난 기계적 강도 (높은 온도에서도) 와 안정적인 물리적 특성을 나타내며, 가혹한 환경에 적합합니다.

2.1 기계적 성질 (해소 고름 후)

| 재산 | 가치 (유형적) | 시험 표준 |

|---|---|---|

| 팽창 강도 | ≥827 MPa (120 ksi) | ASTM E8 |

| 수익력 (0.2% 오프셋) | ≥414 MPa (60 ksi) | ASTM E8 |

| 연장 (50mm) | ≥30% | ASTM E8 |

| 강도 (Brinell) | ≤248 HB | ASTM E10 |

| 충격 강도 (Charpy V Notch, 20°C) | ≥100 J (74 ft-lb) | ASTM E23 |

2.2 물리적 특성

| 재산 | 값 (20°C에서 표시되지 않는 경우) |

|---|---|

| 밀도 | 80.44g/cm3 (0.305lb/in3) |

| 열전도성 | 11.8 W/(m·K) (82 Btu·in/(ft2·h·°F)) |

| 열 확장 계수 (20~100°C) | 12.8 × 10−6/°C (7.1 × 10−6/°F) |

| 전기 저항성 | 1.29 × 10−6 Ω·m (771 Ω·cir-mil/ft) |

| 녹는 범위 | 1290~1350°C |

3제조 및 품질 표준

UNS N06625 둥근 막대 (Inconel 625) 는 일관성과 성능을 보장하기 위해 국제 표준에 따라 생산되고 검사됩니다.

| 표준형 | 관련 표준 |

|---|---|

| 물질적 표준 | - ASTM B446: 니켈-크롬-몰리브덴-콜롬비아 합금 (UNS N06625) 막대, 막대 및 와이어 표준 사양 - ASME SB446: 압력을 포함하는 부품에 대한 보일러 및 압력 용기 코드 (BPVC) 승인 - DIN EN 10269: 니켈 합금 막품에 대한 유럽 표준 - JIS H4552: 니켈-크롬-몰리브덴 합금 막대기의 일본 산업 표준 |

| 차원 표준 | - ASTM B880: 니켈 및 니켈 합금 막대 및 막대에 대한 일반 요구 사항 표준 사양 - ISO 10288: 금속 막대기의 차원 허용량에 대한 국제 표준 |

| 시험 기준 | - ASTM E8 (트렌설 테스트), ASTM E23 (충격 테스트), ASTM E10 (강도 테스트) - ASTM A262 (간알성 경화 시험) - NACE MR0175/ISO 15156: 산성 서비스 (석유/가스용) |

4동등 한 학위

UNS N06625 (Inconel 625) 는 주요 세계 지역에서 표준화 된 동등성을 가지고 있으며 국제 프로젝트의 교환성을 보장합니다.

| 지역 | 동등 한 등급 지정 |

|---|---|

| 미국 | UNS N06625, ASTM B446 (인코넬 625) |

| 유럽 | 가공자물 제2호4856, DIN EN 10269 |

| 일본 | JIS H4552 (NCF625) |

| 중국 | GB/T 15007 (N06625) |

| 국제 (ISO) | ISO 6363-3 (NiCr22Mo9Nb) |

5주요 특징

UNS N06625 둥근 막대는 특유의 특성 조합으로 돋보이며 까다로운 산업의 중요한 과제를 해결합니다.

- 예외적인 경화 저항성: 해수, 산성 용액 (예를 들어,황산수분 염화산), 염화질소가 풍부한 환경. 이것은 높은 크롬과 몰리브덴 함유와 니오비아스 안정화로 인해 발생합니다.

- 고온 성능: 1093°C (2000°F) 까지의 온도에서 기계적 강도와 산화 저항을 유지하며, 장기적인 열 스트레스 아래 중요한 미끄러짐 변형이 없습니다.

- 우수한 제조성: 핫 롤 바는 가공, 조형 또는 용접이 쉽습니다 (ERNiCrMo-3와 같은 적절한 필러 금속); 밝은 바는 정밀 애플리케이션에 최소한의 후처리를 필요로합니다.

- 안정적인 미세 구조: 니오비아스는 융통성을 손상시키지 않고 합금을 강화하는 금속 간 단계 (예를 들어, γ 沉沉) 를 형성합니다.높은 온도에 오랫동안 노출된 후에도 깨지기 쉬운 단계를 피합니다..

6어플리케이션

견고한 특성으로 인해 UNS N06625 둥근 막대기 (6~350mm 지름) 는 극단적인 조건에서 신뢰성을 요구하는 산업에서 널리 사용됩니다.

- 석유 및 가스: 하구관, 우물머리 부품 및 산성 서비스 밸브 (H2S/CO2가 높다); 해저 파이프 라인 및 커넥터 (해수 부식 저항성).

- 항공 및 항공: 터빈 블레이드, 연소 챔버 및 배기가스 시스템 (고온과 열 사이클에 견딜 수 있습니다); 항공기 엔진의 고정 장치 및 구조 부품.

- 화학 처리: 원자로, 열 교환기 및 펌프 샤프트 (산, 알칼리 및 유기 용매와 같은 부식 화학 물질에 저항합니다.)

- 전력 생산: 보일러 튜브, 증기 터빈 부품 및 핵 원자로 내부 (고압 및 열 스트레스 를 견딜 수 있다).

- 해양공학: 프로펠러 샤프트, 선박 선체 부품 및 해상 플랫폼 구조 (해수 뚫림과 생물 오염에 면역)

- 의료 장비: 외과 기구 및 장착 가능한 장치 (생물 호환성 및 체액에서 부식 저항성).

요약하자면 UNS N06625 (Inconel 625) 둥근 막대기 (6?? 350mm, 핫 롤 / 밝은) 는 강도, 부식 저항성 및 다양성의 균형을 제공합니다.고위험 산업에서 중요한 응용 분야에 선호되는 선택이됩니다.

![]()

![]()

![]()

![]()

추천된 제품