All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

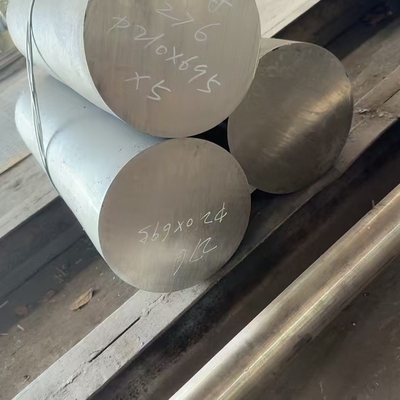

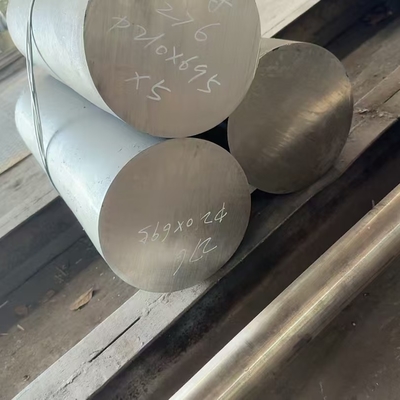

UNS N06625 Nickel Alloy Round Bar Diameter 6 - 350mm Hot Rolled Bars / Bright Bars

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | UNS N06625 / 625 |

| Minimum Order Quantity | 500 kgs |

| Price | 30 - 35 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Nickel Alloy Plate | Grade | UNS N06625 / 625 |

|---|---|---|---|

| Diameter | 6 - 350mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black , Bright |

| Highlight | UNS N06625 nickel alloy round bar,hot rolled nickel alloy bars,bright bars nickel alloy 6-350mm |

||

Product Description

UNS N06625 Nickel Alloy Round Bar Diameter 6 - 350mm Hot Rolled Bars / Bright Bars

More Specification Informations

| Products Name | UNS N06625 Nickel Alloy Round Bar / Rod |

| Diameter | 6.0 - 350mm |

| Length | custom cutting any length as request |

| Surface | Black , bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Regular Diameter of Inconel 625 Round Bar in Stock

| 6mm | 8mm | 9mm | 10mm | 12mm | 14mm |

| 15mm | 16mm | 18mm | 19mm | 20mm | 22mm |

| 25mm | 28mm | 30mm | 32mm | 35mm | 38mm |

| 40mm | 42mm | 45mm | 48mm | 50mm | 55mm |

| 60mm | 65mm | 70mm | 75mm | 80mm | 85mm |

| 90mm | 95mm | 100mm | 105mm | 110mm | 115mm |

| 120mm | 125mm | 130mm | 140mm | 150mm | 160mm |

| 170mm | 180mm | 190mm | 200mm | 210mm | 220mm |

| 230mm | 240mm | 250mm | 260mm | 270mm | 280mm |

| 290mm | 300mm | 310mm | 320mm | 330mm | 340mm |

UNS N06625 Nickel Alloy Round Bar Diameter 6 - 350mm Hot Rolled Bars / Bright Bars

Inconel 625 (designated as UNS N06625) is a premium nickel-chromium-molybdenum alloy renowned for its exceptional corrosion resistance, high-temperature strength, and structural stability—making its round bar form a staple in demanding industrial applications. Below is a comprehensive overview of its parameters, properties, standards, equivalent grades, key features, and typical uses, with a focus on the 6–350mm diameter range for hot rolled and bright bars.

1. Basic Parameters

The UNS N06625 round bars (Inconel 625) covered here adhere to strict dimensional and material specifications, with key parameters outlined as follows:

| Parameter Category | Details |

|---|---|

| Alloy Designation | UNS N06625, Werkstoff No. 2.4856, ASTM B446 (primary for round bars) |

| Diameter Range | 6mm – 350mm (covers small precision bars to large structural bars) |

| Surface Finish | - Hot Rolled Bars: Matte, slightly rough surface (Ra 6.3–12.5μm), suitable for machining or further processing. - Bright Bars: Polished/smooth surface (Ra 0.8–3.2μm), ideal for applications requiring aesthetic or low-friction performance. |

| Length | Standard: 2–6 meters (custom lengths available upon request) |

| Heat Treatment | Typical: Solution annealing at 980–1150°C (1800–2100°F), followed by rapid quenching (water or air cooling) to optimize corrosion resistance and ductility. |

| Chemical Composition | Nickel (Ni): ≥58%; Chromium (Cr): 20–23%; Molybdenum (Mo): 8–10%; Niobium (Nb) + Tantalum (Ta): 3.15–4.15%; Iron (Fe): ≤5%; Carbon (C): ≤0.10%; Manganese (Mn): ≤0.50%; Silicon (Si): ≤0.50%; Phosphorus (P): ≤0.015%; Sulfur (S): ≤0.015%. |

2. Mechanical & Physical Properties

Inconel 625 round bars exhibit outstanding mechanical strength (even at elevated temperatures) and stable physical properties, making them suitable for harsh environments:

2.1 Mechanical Properties (After Solution Annealing)

| Property | Value (Typical) | Test Standard |

|---|---|---|

| Tensile Strength | ≥827 MPa (120 ksi) | ASTM E8 |

| Yield Strength (0.2% Offset) | ≥414 MPa (60 ksi) | ASTM E8 |

| Elongation (in 50mm) | ≥30% | ASTM E8 |

| Hardness (Brinell) | ≤248 HB | ASTM E10 |

| Impact Toughness (Charpy V-Notch, 20°C) | ≥100 J (74 ft-lb) | ASTM E23 |

2.2 Physical Properties

| Property | Value (at 20°C unless noted) |

|---|---|

| Density | 8.44 g/cm³ (0.305 lb/in³) |

| Thermal Conductivity | 11.8 W/(m·K) (82 Btu·in/(ft²·h·°F)) |

| Coefficient of Thermal Expansion (20–100°C) | 12.8 × 10⁻⁶/°C (7.1 × 10⁻⁶/°F) |

| Electrical Resistivity | 1.29 × 10⁻⁶ Ω·m (771 Ω·cir-mil/ft) |

| Melting Range | 1290–1350°C (2350–2460°F) |

3. Manufacturing & Quality Standards

UNS N06625 round bars (Inconel 625) are produced and inspected in compliance with international standards to ensure consistency and performance:

| Standard Type | Relevant Standards |

|---|---|

| Material Standards | - ASTM B446: Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloy (UNS N06625) Bar, Rod, and Wire - ASME SB446: Boiler and Pressure Vessel Code (BPVC) approval for pressure-containing components - DIN EN 10269: European standard for nickel alloy bars - JIS H4552: Japanese Industrial Standard for nickel-chromium-molybdenum alloy bars |

| Dimensional Standards | - ASTM B880: Standard Specification for General Requirements for Nickel and Nickel Alloy Bars and Rods - ISO 10288: International standard for dimensional tolerances of metal bars |

| Testing Standards | - ASTM E8 (Tensile Testing), ASTM E23 (Impact Testing), ASTM E10 (Hardness Testing) - ASTM A262 (Intergranular Corrosion Testing) - NACE MR0175/ISO 15156: For sour service (oil/gas applications) |

4. Equivalent Grades

UNS N06625 (Inconel 625) has standardized equivalents across major global regions, ensuring interchangeability for international projects:

| Region | Equivalent Grade Designation |

|---|---|

| United States | UNS N06625, ASTM B446 (Inconel 625) |

| Europe | Werkstoff No. 2.4856, DIN EN 10269 |

| Japan | JIS H4552 (NCF625) |

| China | GB/T 15007 (N06625) |

| International (ISO) | ISO 6363-3 (NiCr22Mo9Nb) |

5. Key Features

UNS N06625 round bars stand out for their unique combination of properties, addressing critical challenges in demanding industries:

- Exceptional Corrosion Resistance: Resists uniform corrosion, pitting, crevice corrosion, and stress corrosion cracking (SCC) in aggressive media, including seawater, acidic solutions (e.g., sulfuric acid, hydrochloric acid), and chloride-rich environments. This is attributed to its high chromium and molybdenum content, plus niobium stabilization.

- High-Temperature Performance: Maintains mechanical strength and oxidation resistance at temperatures up to 1093°C (2000°F), with no significant creep deformation under long-term thermal stress.

- Excellent Fabricability: Hot rolled bars are easy to machine, forge, or weld (with proper filler metals like ERNiCrMo-3); bright bars require minimal post-processing for precision applications.

- Stable Microstructure: Niobium forms intermetallic phases (e.g., γ” precipitates) that strengthen the alloy without compromising ductility, avoiding brittle phases even after prolonged exposure to high temperatures.

6. Applications

Given its robust properties, UNS N06625 round bars (6–350mm diameter) are widely used in industries requiring reliability under extreme conditions:

- Oil & Gas: Downhole tubulars, wellhead components, and valves for sour service (high H₂S/CO₂);subsea pipelines and connectors (resistant to seawater corrosion).

- Aerospace & Aviation: Turbine blades, combustion chambers, and exhaust systems (withstands high temperatures and thermal cycling);fasteners and structural parts for aircraft engines.

- Chemical Processing: Reactors, heat exchangers, and pump shafts (resists corrosive chemicals like acids, alkalis, and organic solvents).

- Power Generation: Boiler tubes, steam turbine components, and nuclear reactor internals (tolerates high pressure and thermal stress).

- Marine Engineering: Propeller shafts, ship hull components, and offshore platform structures (immune to seawater pitting and biofouling).

- Medical Equipment: Surgical instruments and implantable devices (biocompatible and corrosion-resistant in bodily fluids).

In summary, UNS N06625 (Inconel 625) round bars (6–350mm, hot rolled/bright) offer a balance of strength, corrosion resistance, and versatility, making them a preferred choice for critical applications across high-stakes industries.

![]()

![]()

![]()

![]()

Recommended Products