-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

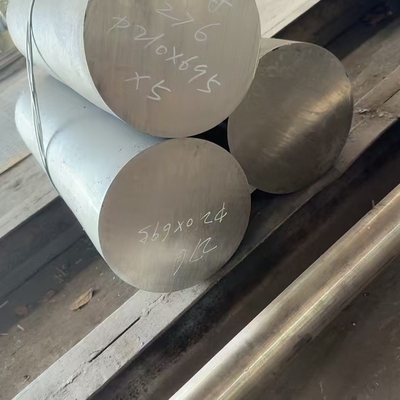

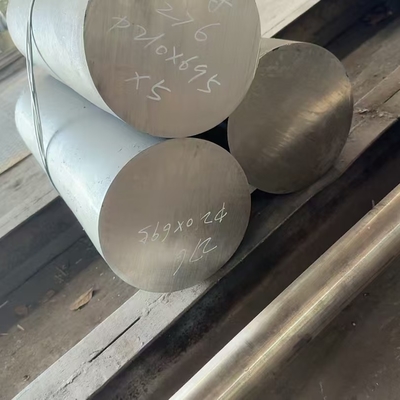

Στρογγυλή ράβδος από κράμα νικελίου UNS N06625 Διάμετρος 6 - 350mm Ράβδοι θερμής έλασης / Φωτεινές ράβδοι

| Τόπος καταγωγής | ΚΙΝΑ |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | UNS N06625 / 625 |

| Ποσότητα παραγγελίας min | 500 κιλά |

| Τιμή | 30 - 35 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Με ελάτε σε επαφή με δωρεάν δείγματα και δελτία.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Εάν έχετε οποιαδήποτε ανησυχία, παρέχουμε τη 24ωρη σε απευθείας σύνδεση βοήθεια.

x| Προϊόντα | Πλάκα από κράμα νικελίου | Βαθμός | UNS N06625 / 625 |

|---|---|---|---|

| Διάμετρος | 6 - 350mm | Μήκος | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Πρότυπο | Astm en | Υπηρεσία | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | Μαύρο, φωτεινό. |

| Επισημαίνω | Στρογγυλή ράβδος από κράμα νικελίου UNS N06625,Ελαστικά από κράμα νικελίου θερμής έλασης,φωτεινές ράβδοι κράματος νικελίου 6-350 mm |

||

UNS N06625 Στρογγυλή ράβδος από κράμα νικελίου Διαμέτρου 6 - 350 mm Ζεστά ελαστικές ράβδους / φωτεινές ράβδους

Περισσότερες πληροφορίες προδιαγραφών

| Ονομασία των προϊόντων | Εθνική Εθνική Σημείωση N06625 Στρογγυλή ράβδος / ράβδος από κράμα νικελίου |

| Διάμετρος | 6.0 - 350 mm |

| Διάρκεια | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Επιφάνεια | Μαύρο, φωτεινό. |

| Ετικέτα | ΔΕΛΤΑ |

| Υπηρεσία | Κόψιμο, γυαλισμός |

| Τροποποιημένο | 2 κιλά |

| Άλλος τύπος | Στρογγυλή ράβδο, ταινία, τροχιά, σωλήνα, φύλλο, πλάκα, σύρμα κλπ. |

| Συσκευή | υδατοασφαλές χαρτί και ξύλινες παλέτες, ξύλινο κουτί |

| Λιμένας φόρτωσης | Λιμάνι της Σαγκάης |

| Όρος τιμής | Επικαιροποιημένα προϊόντα |

| Χρόνος παράδοσης | εντός 12 ημερών |

Κανονική διάμετρος Inconel 625 στρογγυλή μπάρα σε απόθεμα

| 6 χιλιοστά | 8 χιλιοστά | 9 χιλιοστά | 10 χιλιοστά | 12 χιλιοστά | 14 χιλιοστά |

| 15 χιλιοστά | 16 χιλιοστά | 18 χιλιοστά | 19 χιλιοστά | 20 χιλιοστά | 22 χιλιοστά |

| 25 χιλιοστά | 28 χιλιοστά | 30 χιλιοστά | 32 χιλιοστά | 35 χιλιοστά | 38 χιλιοστά |

| 40 χιλιοστά | 42 χιλιοστά | 45 χιλιοστά | 48 χιλιοστά | 50 χιλιοστά | 55 χιλιοστά |

| 60 χιλιοστά | 65 χιλιοστά | 70 χιλιοστά | 75 χιλιοστά | 80 χιλιοστά | 85 χιλιοστά |

| 90 χιλιοστά | 95 χιλιοστά | 100 χιλιοστά | 105 χιλιοστά | 110 χιλιοστά | 115 χιλιοστά |

| 120 χιλιοστά | 125 χιλιοστά | 130 χιλιοστά | 140 χιλιοστά | 150 χιλιοστά | 160 χιλιοστά |

| 170 χιλιοστά | 180 χιλιοστά | 190 χιλιοστά | 200 χιλιοστά | 210 χιλιοστά | 220 χιλιοστά |

| 230 χιλιοστά | 240 χιλιοστά | 250 χιλιοστά | 260 χιλιοστά | 270 χιλιοστά | 280 χιλιοστά |

| 290 χιλιοστά | 300 χιλιοστά | 310 χιλιοστά | 320 χιλιοστά | 330 χιλιοστά | 340 χιλιοστά |

UNS N06625 Στρογγυλή ράβδος από κράμα νικελίου Διαμέτρου 6 - 350 mm Ζεστά ελαστικές ράβδους / φωτεινές ράβδους

1. Βασικές παραμέτρους

| Κατηγορία παραμέτρου | Λεπτομέρειες |

|---|---|

| Ονομασία κράματος | Η UNS N06625, Werkstoff αριθ. 2.4856, ASTM B446 (πρωτογενής για στρογγυλές ράβδους) |

| Περιοχή διαμέτρου | 6 mm 350 mm (περιλαμβάνει μικρές ράβδους ακριβείας έως μεγάλες δομικές ράβδους) |

| Τελεία επιφάνειας | - Ζεστά κυλούμενα ράβδοι: Ματ, ελαφρώς τραχιά επιφάνεια (Ra 6,3·12,5μm), κατάλληλη για επεξεργασία ή περαιτέρω επεξεργασία. - Φωτεινές μπάρες: γυαλισμένη/ομαλή επιφάνεια (Ra 0,8·3,2μm), ιδανική για εφαρμογές που απαιτούν αισθητικές ή χαμηλές επιδόσεις τριβής. |

| Διάρκεια | Πρότυπο: 2 ̊6 μέτρα (προσαρμοσμένα μήκη διαθέσιμα κατόπιν αιτήματος) |

| Θερμική επεξεργασία | Τυπικό: Επεξεργασία με διάλυμα σε θερμοκρασία 980-1150 °C (1800-2100 °F), ακολουθούμενη από ταχεία ψύξη (ψύξη με νερό ή αέρα) για τη βελτιστοποίηση της αντοχής στη διάβρωση και της ευκαμψίας. |

| Χημική σύνθεση | Νικέλιο (Ni): ≥58%· Χρώμιο (Cr): 20·23%· Μολυβδανό (Mo): 8·10%· Νιοβίο (Nb) + Ταντάλλο (Ta): 3,15·4,15%· Σίδηρο (Fe): ≤5%· Άνθρακας (C): ≤0,10%· Μαγγάνιο (Mn): ≤0,50%· Σίληνιο (Si): ≤0,50%·Φωσφόρος (P): ≤ 0,015%; Θείο (S): ≤ 0,015%. |

2Μηχανικές και φυσικές ιδιότητες

2.1 Μηχανικές ιδιότητες (μετά την αναψύξη διαλύματος)

| Ιδιοκτησία | Αξία (τυπική) | Πρότυπο δοκιμής |

|---|---|---|

| Δυνατότητα τράβηξης | ≥ 827 MPa (120 ksi) | ΑΣTM E8 |

| Δυνατότητα απόδοσης (0,2% αντιστάθμιση) | ≥414 MPa (60 ksi) | ΑΣTM E8 |

| Επεκτάσεις (σε 50 mm) | ≥ 30% | ΑΣTM E8 |

| Σκληρότητα (Brinell) | ≤ 248 HB | ΑΣTM E10 |

| Δυνατότητα κρούσης (Charpy V-Notch, 20°C) | ≥ 100 J (74 ft-lb) | ΑΣTM E23 |

2.2 Φυσικές ιδιότητες

| Ιδιοκτησία | Αξία (σε θερμοκρασία 20°C, εκτός εάν αναφέρεται) |

|---|---|

| Σφιχτότητα | 80,44 g/cm3 (0,305 lb/in3) |

| Θερμική αγωγιμότητα | 11.8 W/(m·K) (82 Btu·in/(ft2·h·°F)) |

| Συντελεστής θερμικής επέκτασης (20-100°C) | 12.8 × 10−6/°C (7,1 × 10−6/°F) |

| Ηλεκτρική αντίσταση | 1.29 × 10−6 Ω·m (771 Ω·cir-mil/ft) |

| Πεδίο τήξης | 1290°1350°C (2350°2460°F) |

3. Παρασκευή & Πρότυπα Ποιότητας

| Τύπος πρότυπο | Σχετικά πρότυπα |

|---|---|

| Υλικά Πρότυπα | - ASTM B446: Τυπική προδιαγραφή για κράμα νικελίου-χρώμου-μολυβδενίου-κολμβίου (UNS N06625) ράβδος, ράβδος και σύρμα - ASME SB446: Κώδικας για τις λέβητες και τα δοχεία υπό πίεση (BPVC) έγκριση για τα κατασκευαστικά στοιχεία που περιέχουν υλικά υπό πίεση - DIN EN 10269: Ευρωπαϊκό πρότυπο για ράβδους κράματος νικελίου - JIS H4552: Ιαπωνικό Βιομηχανικό Πρότυπο για ράβδους κράματος νικελίου-χρωμίου-μολυβδενίου |

| Τμήματα | - ASTM B880: Τυποποιημένη προδιαγραφή γενικών απαιτήσεων για ράβδους και ράβδους νικελίου και κράματος νικελίου - ISO 10288: Διεθνές πρότυπο για τις ανοχές διαστάσεων των μεταλλικών ράβδων |

| Πρότυπα δοκιμών | - ASTM E8 (Ελέγχος τεντώσεως), ASTM E23 (Ελέγχος αντίκτυπου), ASTM E10 (Ελέγχος σκληρότητας) - ASTM A262 (Διασωματική δοκιμή διάβρωσης) - NACE MR0175/ISO 15156: Για την αλκοολική διατροφή (εφαρμογές πετρελαίου/αερίου) |

4. Εξισοδύναμες βαθμίδες

| Περιφέρεια | Ονομασία ισοδύναμου βαθμού |

|---|---|

| Ηνωμένες Πολιτείες | Επικαιροποιημένο υλικό |

| Ελλάδα | Υλικό αριθ. 2.4856, DIN EN 10269 |

| Ιαπωνία | Δελτίο ΕΚΑΧ αριθ. |

| Κίνα | GB/T 15007 (N06625) |

| Διεθνής (ISO) | ISO 6363-3 (NiCr22Mo9Nb) |

5Βασικά χαρακτηριστικά

- Εξαιρετική αντοχή στη διάβρωση: Αντιστέκεται στην ομοιόμορφη διάβρωση, τη διάβρωση, τη διάβρωση των ρωγμών και τη διάβρωση από διάβρωση υπό πίεση (SCC) σε επιθετικά μέσα, συμπεριλαμβανομένου του θαλασσινού νερού, των οξέων διαλύσεων (π.χ.θειικό οξύΑυτό οφείλεται στην υψηλή περιεκτικότητά του σε χρώμιο και μολυβδένιο, καθώς και στη σταθεροποίηση του νιοβίου.

- Δυναμικότητα σε υψηλές θερμοκρασίες: Διατηρεί μηχανική αντοχή και αντοχή στην οξείδωση σε θερμοκρασίες έως 1093 °C (2000 °F), χωρίς σημαντική παραμόρφωση μετά την έλξη υπό μακροχρόνια θερμική πίεση.

- Εξαιρετική κατασκευαστικότητα: Οι ζεστές ράβδοι είναι εύκολες στη μηχανική, στη σφυρηλασία ή στη συγκόλληση (με κατάλληλα μέταλλα πλήρωσης όπως το ERNiCrMo-3) · οι φωτεινές ράβδοι απαιτούν ελάχιστη μεταπεξεργασία για εφαρμογές ακριβείας.

- Σταθερή μικροδομή: Το νιόμπιου σχηματίζει διαμεταλλικές φάσεις (π.χ. βροχές γ) που ενισχύουν το κράμα χωρίς να διακυβεύεται η ευελιξία του,αποφυγή εύθραυστων φάσεων ακόμη και μετά από παρατεταμένη έκθεση σε υψηλές θερμοκρασίες.

6Εφαρμογές

- Πετρέλαιο και φυσικό αέριο: σωληνώματα κάτω από το λάκκο, εξαρτήματα κεφαλής πηγάδι, βαλβίδες για την παροχή οξέος (υψηλή ποσότητα H2S/CO2) · υποθαλάσσιοι αγωγοί και συνδέσεις (ανθεκτικοί στη διάβρωση από το θαλάσσιο νερό).

- Αεροδιαστημική & Αεροπορία: Λεπίδες τουρμπίνων, θάλαμοι καύσης και συστήματα εξάτμισης (αντέχει υψηλές θερμοκρασίες και θερμικούς κύκλους)

- Χημική επεξεργασία: αντιδραστήρες, ανταλλακτές θερμότητας και άξονες αντλίας (αντιστέκει σε διαβρωτικά χημικά όπως οξέα, αλκαλικά και οργανικά διαλύτες).

- Ηλεκτρική παραγωγή: σωλήνες λέβητα, εξαρτήματα ατμογεννητριών και εσωτερικά του πυρηνικού αντιδραστήρα (αντέχει υψηλή πίεση και θερμική πίεση).

- Ναυτική μηχανική: Άξονες προπέλας, κατασκευαστικά στοιχεία σκελετού πλοίου και δομές πλατφόρμας υπεράκτιας θάλασσας (απορρόφητη από την παρακμή και τη βιοφθορά του θαλασσινού νερού).

- Ιατρικός εξοπλισμός: Χειρουργικά όργανα και εμφυτεύσιμες συσκευές (βιοσυμβατές και ανθεκτικές στη διάβρωση σε σωματικά υγρά).

![]()

![]()

![]()

![]()