Tutti i prodotti

-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

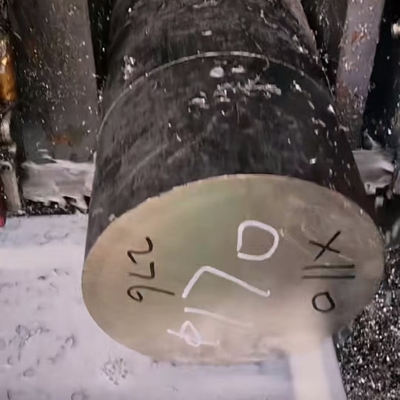

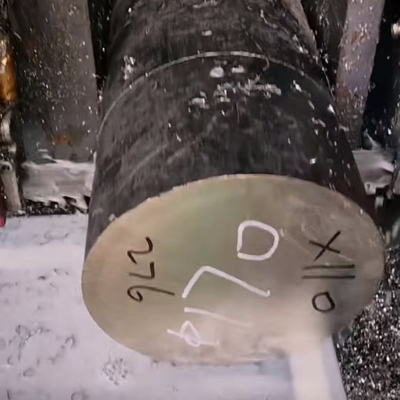

Hastelloy C276 Forgiato Bar Rotonda Diametro 140 - 350 mm Taglio su misura di qualsiasi lunghezza Lega C276 Rod

| Luogo di origine | Cina |

|---|---|

| Marca | DELTA |

| Certificazione | ISO |

| Numero di modello | c276 |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 40-45 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 3 tonnellate a settimana |

Dettagli

| Prodotti | Placca in lega di nichel | Grado | c276 |

|---|---|---|---|

| Diametro | 6 - 350 mm | Lunghezza | taglio su misura di qualsiasi lunghezza su richiesta |

| Standard | Astm en | Servizio | Taglio |

| Porta di caricamento | Shanghai Port | Superficie | nero, luminoso |

| Evidenziare | Hastelloy C276 forged round bar,Nickel alloy C276 rod,Custom cut Hastelloy C276 bar |

||

Descrizione di prodotto

Hastelloy C276 Forgiato Bar Rotonda Diametro 140 - 350 mm Taglio su misura di qualsiasi lunghezza Lega C276 Rod

Informazioni veloci

| Grado | Hastelloy C276 / 2.4819 | Forma | Barra rotonda |

| Diametro | 6.0 - 350 mm | Tipo | Scaldacciato, forgiato |

| Distanze | Taglio personalizzato di qualsiasi lunghezza su richiesta | Certificato | EN 10204-3.1 |

Maggiori informazioni sulle specifiche

| Nome dei prodotti | Hastelloy C276 barra rotonda / canna |

| Diametro | 6.0 - 350 mm |

| Distanze | taglio su misura di qualsiasi lunghezza su richiesta |

| Superficie | Nero, luminoso. |

| Marchio | DELTA |

| Servizio | taglio |

| MOQ | 2 kg |

| Altri tipi | Barra rotonda, striscia, bobina, tubo, foglio, piastra, filo, ecc. |

| Imballaggio | carta impermeabile e pallet di legno, scatola di legno |

| Porto di carico | Porto di Shanghai |

| Termine del prezzo | EXW, FOB, CIF, CFR |

| Tempo di consegna | entro 12 giorni |

1. Specificativi di base (140-350 mm Barra rotonda forgiata)

Le dimensioni e i parametri chiave di questa barra rotonda Hastelloy C276 sono ottimizzati per l'uso industriale pesante, la resistenza di bilanciamento e la lavorabilità.

| Parametro | Specificità |

|---|---|

| Forma del prodotto | Barre rotonde forgiate (forate a caldo per una maggiore densità e struttura dei grani) |

| Intervallo di diametro | 140 mm 350 mm (forgiato per una tolleranza dimensionale ristretta; diametri personalizzati disponibili su richiesta) |

| Distanze | Disponibile per il taglio su misura (qualsiasi lunghezza, ad esempio 100 mm, 500 mm, 1000 mm, fino a 6000 mm; nessuna restrizione di lunghezza minima) |

| Processo di forgiatura | Forgiazione a caldo (temperatura: 1150°C - 1230°C) seguita da ricottura per alleviare lo stress |

| Finitura superficiale | Superficie forgiata (come forgiata: strato di leggera ossidazione) o superficie in aceto (facoltativo, per aumentare la resistenza alla corrosione) |

| Tolleranza (Diametro) | ASTM A480/A480M: ±0,5 mm per diametri ≤ 200 mm; ±0,8 mm per diametri > 200 mm |

| Tolleranza (lunghezza) | Tolleranza di lunghezza del taglio su misura: ±1 mm (standard) o ±0,5 mm (taglio di precisione) |

2Composizione chimica

L'eccezionale resistenza alla corrosione della lega Hastelloy C276 deriva dai suoi elementi di lega equilibrati con precisione,con basso contenuto di carbonio e silicio per prevenire la precipitazione di carburo (una causa comune di corrosione intergranulare).

| Elemento | Intervallo di contenuto (%) | Funzione chiave |

|---|---|---|

| Nilo (Ni) | 56.0 min | Metallo comune; fornisce duttilità e resistenza agli ambienti riducenti |

| Molibdeno (Mo) | 15.0 ¢ 17.0 | Migliora la resistenza alle crepe, alla corrosione delle fessure e all'acido solforico |

| Cromo (Cr) | 14.5 ¢ 16.5 | Aumenta la resistenza all'ossidazione e la resistenza agli acidi ossidanti (ad esempio acido nitrico) |

| Ferro (Fe) | 4.0 ¢ 7.0 | Migliora la resistenza meccanica e la lavorabilità della forgiatura |

| Volframmo (W) | 3.0 ¢ 4.5 | Sinergia con Mo per aumentare la resistenza alla corrosione da buco in mezzi ricchi di cloruro |

| Cobalto (Co) | 2.5 massimo | Controlla la duttilità delle leghe e riduce la fragilità |

| Carbonio (C) | 0.01 massimo | Minimizza la formazione di carburo (critico per la saldabilità) |

| Silicio (Si) | 0.08 massimo | Previene l'ossidazione durante la lavorazione ad alta temperatura |

| Fosforo (P) | 0.04 massimo | Limita le impurità per evitare la fragilità |

| Sulfuro (S) | 0.03 massimo | Riduce il rischio di cracking a caldo durante la forgiatura e la saldatura |

3. Performance meccanica e corrosiva

Questa lega eccelle sia per la resistenza meccanica che per la resistenza alla corrosione, rendendola adatta a componenti portanti in ambienti aggressivi.

3.1 Proprietà meccaniche (in condizione di annelamento)

| Immobili | Valore (tipico) |

|---|---|

| Resistenza alla trazione (σb) | ≥ 690 MPa |

| Resistenza al rendimento (σ0,2) | ≥ 310 MPa |

| Allungamento (δ) | ≥ 40% (in lunghezza di calibro di 50 mm) |

| Durezza (HB) | ≤ 210 |

| Durezza all'impatto (intaglio in V di Charpy) | ≥ 100 J (a temperatura ambiente) |

| Temperatura massima di funzionamento | 1093°C (a breve termine); 649°C (a lungo termine, per la resistenza all'ossidazione continua) |

3.2 Resistenza alla corrosione

La Hastelloy C276 è rinomata come una delle leghe più resistenti alla corrosione a livello mondiale, resistente a:

- Acidi riducenti: acido solforico (concentrazione fino al 90%), acido cloridrico (diluito a concentrazioni moderate) e acido fosforico.

- Acidi ossidanti: acido nitrico (diluito), acido cromico e acidi misti (ad esempio, pioggia acida, processi chimici).

- Mezzi ricchi di cloruro: acqua di mare, salamoie e soluzioni di cloruro (resistente alla corrosione delle fessure e delle fessure, fondamentale per le applicazioni marine e offshore).

- Ambienti ad alta temperatura: Resiste all'ossidazione e alla solfidazione nei gas di combustione, negli inceneritori e nei reattori petrolchimici.

Principale vantaggio: a differenza di molti acciai inossidabili, non richiede un trattamento termico post-saldatura (PWHT) per mantenere la resistenza alla corrosione, semplificando la fabbricazione.

4. Norme di fabbricazione e qualità

Le barre rotonde forgiate Hastelloy C276 rispettano severi standard internazionali per garantire coerenza e affidabilità.

| Categoria standard | Norme pertinenti |

|---|---|

| Composizione chimica | ASTM B574, ASME SB574, DIN EN 10095 |

| Forgia e dimensione | ASTM A480/A480M (piattazza/tolleranza), ISO 898-6 (qualità della forgiatura) |

| Proprietà meccaniche | ASTM B574, ASME SB574, BS 3074 (parte NA16) |

| Requisiti di prova | - Prova non distruttiva (NDT): prova ad ultrasuoni (UT) per ASTM A609 (100% di copertura per i difetti) - Analisi chimica: prove spettrometriche - prove meccaniche: prove di trazione, durezza e d'urto (per lotto) |

| Qualità della superficie | ASTM A788 (per superfici in salamoia) o ASTM A967 (passivazione, facoltativa) |

5. Gradi equivalenti

L'Hastelloy C276 è commercializzato in tutto il mondo con denominazioni diverse; questi gradi sono chimicamente e prestazionalmente equivalenti:

| Standard/Regione | Grado equivalente |

|---|---|

| ASTM/ASME (USA) | UNS N10276, lega C276 |

| DIN EN (Europa) | W. N. 2.4819 |

| BS (Regno Unito) | NA16 |

| JIS (Giappone) | NW 276 |

| GB (Cina) | NS334 |

| ISO | NiMo16Cr15W (ISO 15156-3) |

Nota: sebbene questi gradi siano intercambiabili nella maggior parte delle applicazioni, si deve sempre confermare la conformità alle norme specifiche del progetto (ad esempio, ASME BPVC per i recipienti a pressione).

6Applicazioni

La barra rotonda forgiata Hastelloy C276 di 140-350 mm di diametro, con la sua lunghezza opzionale, è ideale per componenti pesanti e di grandi dimensioni che richiedono resistenza e resistenza alla corrosione.Le principali applicazioni comprendono::

- Petrochimica e raffinazione: Reattori, recipienti a pressione e tubi per scambiatori di calore (resistono all'acido solforico e al solfuro di idrogeno).

- Marine & Offshore: pozzi di elica, valvole e componenti per il trattamento dell'acqua di mare (resiste alla corrosione dell'acqua di mare e al biofouling).

- Processo chimico: pompe, valvole e agitatori per la produzione di acidi (ad esempio, impianti di acido solforico, cloridrico e nitrico).

- Incinerazione dei rifiuti: rivestimenti dei forni e condotti dei gas di scarico (resistenti all'ossidazione ad alta temperatura e alle ceneri acide).

- Aerospaziale e difesa: componenti del motore e ugelli del razzo (tollerano alte temperature e combustibili aggressivi).

7. Personalizzazione e servizi a valore aggiunto

Per soddisfare le diverse esigenze del progetto, sono disponibili le seguenti personalizzazioni per questa barra rotonda Hastelloy C276:

- Taglio di lunghezza: qualsiasi lunghezza (da segmenti brevi a barre di lunghezza intera) mediante segatura di precisione o taglio a plasma (non esiste un numero minimo di ordini per i diametri standard).

- Trattamento superficiale: decapaggio, passivazione o macinazione (per esigenze di rugosità superficiale stretta, ad esempio, Ra ≤ 0,8 μm).

- Trattamento termico: ricottura (standard), ricottura in soluzione o riduzione dello stress (secondo le specifiche del cliente).

- Certificazioni: certificati di collaudo (MTC) secondo la norma EN 10204 (3.1B o 3.2), conformità alla NACE MR0175/ISO 15156 (per applicazioni di gas acidi) e approvazione FDA (per la lavorazione chimica alimentare).

![]()

![]()

![]()

![]()

Prodotti raccomandati