Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

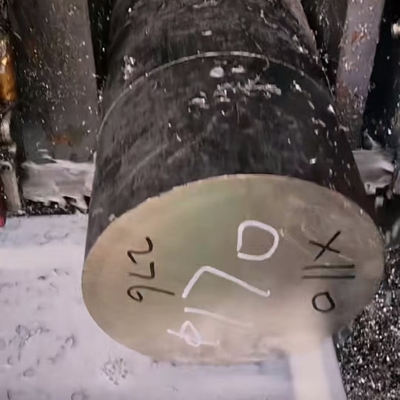

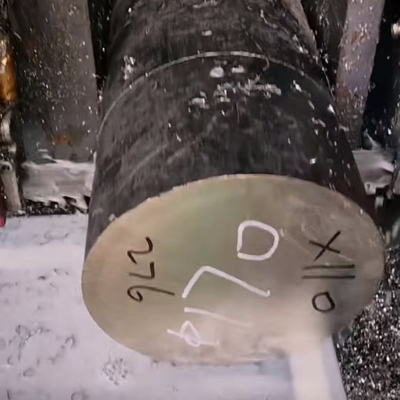

Σφυρήλατη στρογγυλή ράβδος Hastelloy C276 Διάμετρος 140 - 350mm Προσαρμοσμένο κόψιμο σε οποιοδήποτε μήκος Κράμα C276 Ράβδος

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | c276 |

| Ποσότητα παραγγελίας min | 500 κιλά |

| Τιμή | 40-45 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Λεπτομέρειες

| Προϊόντα | Πλάκα από κράμα νικελίου | Βαθμός | c276 |

|---|---|---|---|

| Διάμετρος | 6 - 350mm | Μήκος | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Πρότυπο | Astm en | Υπηρεσία | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | Μαύρο, φωτεινό. |

| Επισημαίνω | Hastelloy C276 forged round bar,Nickel alloy C276 rod,Custom cut Hastelloy C276 bar |

||

Περιγραφή προϊόντων

Hastelloy C276 σφυρηλατημένη στρογγυλή ράβδος διάμετρος 140 - 350 mm Custom κόψιμο οποιουδήποτε μήκους κράμα C276 ράβδος

Γρήγορες πληροφορίες

| Αξία | Χέιστελοϊ C276 / 2.4819 | Σχήμα | Στρογγυλή μπάρα |

| Διάμετρος | 6.0 - 350 mm | Τύπος | Ζεστά τυλιγμένα, σφυρηλατημένα |

| Διάρκεια | Προσαρμοσμένο Κόψιμο οποιουδήποτε μήκους κατά παραγγελία | Πιστοποιητικό | EN 10204-3.1 |

Περισσότερες πληροφορίες προδιαγραφών

| Ονομασία των προϊόντων | Χαστέλλοι C276 στρογγυλή ράβδο |

| Διάμετρος | 6.0 - 350 mm |

| Διάρκεια | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Επιφάνεια | Μαύρο, φωτεινό. |

| Ετικέτα | ΔΕΛΤΑ |

| Υπηρεσία | κοπή |

| Τροποποιημένο | 2 κιλά |

| Άλλος τύπος | Στρογγυλή ράβδο, ταινία, τροχιά, σωλήνα, φύλλο, πλάκα, σύρμα κλπ. |

| Συσκευή | υδατοασφαλές χαρτί και ξύλινες παλέτες, ξύλινο κουτί |

| Λιμένας φόρτωσης | Λιμάνι της Σαγκάης |

| Όρος τιμής | Επικαιροποιημένα προϊόντα |

| Χρόνος παράδοσης | εντός 12 ημερών |

1. Κεντρικές προδιαγραφές (140-350 mm σφυρηλατημένη στρογγυλή ράβδος)

Οι διαστάσεις και οι βασικές παραμέτροι αυτής της στρογγυλής ράβδου Hastelloy C276 είναι βελτιστοποιημένες για βαριά βιομηχανική χρήση, αντοχή ισορροπίας και μηχανική ικανότητα.

| Παράμετρος | Προδιαγραφές |

|---|---|

| Φόρμα προϊόντος | Σφυρηλατημένες στρογγυλές ράβδοι (σφυρηλατημένες σε θερμότητα για βελτίωση της πυκνότητας και της δομής των κόκκων) |

| Περιοχή διαμέτρου | 140 mm 350 mm (σφυρηλατημένο σε στενή ανοχή διαστάσεων, διαμέτροι προσαρμοσμένοι διαθέσιμοι κατόπιν αιτήματος) |

| Διάρκεια | Διαθέσιμη εξατομικευμένη κοπή (όποιο μήκος, π.χ. 100 mm, 500 mm, 1000 mm, έως 6000 mm, χωρίς περιορισμούς ελάχιστου μήκους) |

| Διαδικασία σφυρηλασίας | Ζεστή σφυρηλασία (περίοδος θερμοκρασίας: 1150°C ∼ 1230°C) ακολουθούμενη από αναψύξη για την ελάφρυνση της πίεσης |

| Τελεία επιφάνειας | Σφυρηλατημένη επιφάνεια (ως σφυρηλατημένη: ελαφρύ στρώμα οξείδωσης) ή επιφάνεια ακινητοποιημένη (προαιρετική, για την ενίσχυση της αντοχής στη διάβρωση) |

| Ανεπάρκεια (διάμετρος) | ΑΣTM A480/A480M: ±0,5 mm για διαμέτρους ≤ 200 mm· ±0,8 mm για διαμέτρους > 200 mm |

| Ανεκτικότητα (μήκος) | Διάκριση μήκους με ειδική κοπή: ±1 mm (πρότυπο) ή ±0,5 mm (ακριβής κοπή) |

2Χημική σύνθεση

Η εξαιρετική αντοχή του Hastelloy C276 στην διάβρωση οφείλεται στα ακριβώς ισορροπημένα στοιχεία του,με χαμηλή περιεκτικότητα σε άνθρακα και πυρίτιο για την πρόληψη της βροχόπτωσης καρβιδίων (μια κοινή αιτία διασωματικής διάβρωσης).

| Στοιχείο | Περιοχή περιεχομένου (%) | Βασική λειτουργία |

|---|---|---|

| Νικέλιο (Ni) | 560,0 λεπτά | Βασικό μέταλλο: παρέχει ευελιξία και αντοχή σε περιοριστικά περιβάλλοντα |

| Μολυβδένιο (Mo) | 15.0 ∙ 17.0 | Βελτιώνει την αντοχή σε οπήματα, διάσπαση διαβρώσεως και θειικό οξύ |

| Χρώμιο (Cr) | 14.5 ̇ 16.5 | Ενισχύει την αντοχή στην οξείδωση και την αντοχή στα οξειδωτικά οξέα (π.χ. νιτρικό οξύ) |

| Σίδηρος (Fe) | 4.0 ¢ 7.0 | Βελτιώνει τη μηχανική αντοχή και την εργασιακή ικανότητα της σφυρηλασίας |

| Τούλφραμ (W) | 3.0 ️ 4.5 | Συνεργάζεται με το Mo για την ενίσχυση της αντοχής στη διάβρωση σε υλικά πλούσια σε χλωρίδια |

| Κοβάλτιο (Co) | 2.5 μέγιστο | Ελέγχει την ευελιξία του κράματος και μειώνει την εύθραυστη του |

| Άνθρακας (C) | 0.01 το πολύ | Ελαχιστοποιεί το σχηματισμό καρβιδίου (κρίσιμο για την συγκολλητικότητα) |

| Σιλικόνη (Si) | 0.08 το πολύ | Προλαμβάνει την οξείδωση κατά την επεξεργασία σε υψηλές θερμοκρασίες |

| Φωσφόρος (P) | 0.04 το πολύ | Περιορίζει τις ακαθαρσίες για να αποφευχθεί η εύθραυστη |

| Θείο (S) | 0.03 το πολύ | Μειώνει τον κίνδυνο θερμής ρωγμάτωσης κατά τη σφυρηλάτηση και την συγκόλληση |

3Μηχανολογικές και διαβρωτικές ικανότητες

Αυτό το κράμα ξεχωρίζει τόσο ως προς τη μηχανική αντοχή όσο και ως προς την αντοχή στη διάβρωση, καθιστώντας το κατάλληλο για φορτωτικά εξαρτήματα σε επιθετικά περιβάλλοντα.

3.1 Μηχανικές ιδιότητες (καύση)

| Ιδιοκτησία | Αξία (τυπική) |

|---|---|

| Δυνατότητα τέντωσης (σb) | ≥ 690 MPa |

| Δυνατότητα απόδοσης (σ0,2) | ≥310 MPa |

| Επεκτάσεις (δ) | ≥ 40% (σε μήκος διαμέτρου 50 mm) |

| Σκληρότητα (HB) | ≤210 |

| Δυνατότητα πρόσκρουσης (Charpy V-notch) | ≥ 100 J (σε θερμοκρασία δωματίου) |

| Μέγιστη θερμοκρασία λειτουργίας | 1093°C (σύντομη) · 649°C (μακροχρόνια, για συνεχή αντοχή στην οξείδωση) |

3.2 Αντίσταση στη διάβρωση

Το Hastelloy C276 είναι γνωστό ως ένα από τα πιο ανθεκτικά στη διάβρωση κράματα παγκοσμίως, αντέχοντας:

- Ελαττωτικά οξέα: θειικό οξύ (έως συγκέντρωση 90%), υδροχλωρικό οξύ (διαλυμένο σε μέτρια συγκέντρωση) και φωσφορικό οξύ.

- Οξειδωτικά οξέα: Νιτρικό οξύ (αραίωση), χρωμικό οξύ και μικτά οξέα (π.χ. όξινη βροχή, ροές χημικών διεργασιών).

- Υλικά πλούσια σε χλωρίδιο: θαλασσινό νερό, άλμη και διαλύματα χλωριούχου (αντιστέκεται στη διάβρωση και τη διάσπαση της διάσπασης) κρίσιμη για θαλάσσιες και υπεράκτιες εφαρμογές.

- Περιβάλλον υψηλών θερμοκρασιών: Αντιστέκεται στην οξείδωση και την θειοποίηση στα καυσαέρια, στους αποτεφρωτήρες και στους πετροχημικούς αντιδραστήρες.

Βασικό πλεονέκτημα: Σε αντίθεση με πολλούς ανοξείδωτους χάλυβες, δεν απαιτεί θερμική επεξεργασία μετά το συγκόλλημα (PWHT) για τη διατήρηση της αντοχής στη διάβρωση, απλοποιώντας την κατασκευή.

4. Παρασκευή & Πρότυπα Ποιότητας

Οι σφυρηλατημένες στρογγυλές ράβδοι Hastelloy C276 συμμορφώνονται με αυστηρά διεθνή πρότυπα για να εξασφαλίσουν τη συνέπεια και την αξιοπιστία.

| Τυπική κατηγορία | Σχετικά πρότυπα |

|---|---|

| Χημική σύνθεση | Ειδικότερα, η μέθοδος ASTM B574, ASME SB574, DIN EN 10095 |

| Σφυρηλάτηση και διαστάσεις | ASTM A480/A480M (επίπεδα/ανεπάρκεια), ISO 898-6 (ποιότητα σφυρηλάτησης) |

| Μηχανικές ιδιότητες | Ειδικότερα, οι ενδείξεις που αναφέρονται στο σημείο 1 πρέπει να ισχύουν για τις συσκευές που χρησιμοποιούνται για την κατασκευή των ειδών που αναφέρονται στο σημείο 2 του παρόντος παραρτήματος. |

| Απαιτήσεις δοκιμής | - Μη καταστροφική δοκιμή (NDT): υπερηχητική δοκιμή (UT) σύμφωνα με την ASTM A609 (100% κάλυψη για ελαττώματα) - Χημική ανάλυση: Φασματομετρικές δοκιμές - Μηχανολογικές δοκιμές: δοκιμές ελαστικότητας, σκληρότητας και συγκρούσεων (ανά παρτίδα) |

| Ποιότητα της επιφάνειας | ASTM A788 (για επιφάνεια ακινητοποιημένη) ή ASTM A967 (παστικοποίηση, προαιρετική) |

5. Εξισοδύναμες βαθμίδες

Το Hastelloy C276 διατίθεται στο εμπόριο με διαφορετικές ονομασίες παγκοσμίως.

| Πρότυπο/Περιοχή | Εξισοδύναμη βαθμίδα |

|---|---|

| ΑΣΤΜ/ΑΣΜΕ (ΗΠΑ) | Εθνική Εθνική Στατιστική N10276, κράμα C276 |

| DIN EN (Ευρώπη) | W. Νο. 2.4819 |

| BS (Ηνωμένο Βασίλειο) | NA16 |

| ΔΕΣ (Ιαπωνία) | NW 276 |

| GB (Κίνα) | NS334 |

| ISO | NiMo16Cr15W (ISO 15156-3) |

Σημείωση: Παρόλο που οι βαθμίδες αυτές είναι εναλλακτικές στις περισσότερες εφαρμογές, πρέπει πάντα να επιβεβαιώνεται η συμμόρφωση με τα ειδικά πρότυπα του έργου (π.χ. ASME BPVC για δοχεία υπό πίεση).

6Εφαρμογές

Η σφυρηλατημένη στρογγυλή ράβδος Hastelloy C276 διαμέτρου 140-350 mm με επιλογή προσαρμοσμένου μήκους είναι ιδανική για μεγάλα, βαριά εξαρτήματα που απαιτούν τόσο αντοχή όσο και αντοχή στη διάβρωση.Οι βασικές εφαρμογές περιλαμβάνουν:

- Πετροχημικές και διύλιση: αντιδραστήρες, δοχεία υπό πίεση και σωλήνες ανταλλακτών θερμότητας (αντιστέκονται στο θειικό οξύ και το θειικό υδρογόνο).

- Θαλάσσια και ανοικτή θάλασσα: Άξονες προπέλας, στελέχη βαλβίδων και εξαρτήματα χειρισμού θαλασσινού νερού (αντιστέκει στη διάβρωση και τη βιοφθορά από το θαλασσινό νερό).

- Χημική επεξεργασία: αντλίες, βαλβίδες και αναμειγνυτές για την παραγωγή οξέων (π.χ. εργοστάσια θειικού, υδροχλωρικού και αζώτου).

- Καύση αποβλήτων: Εφοδιασμοί κλιβάνων και σωλήνες καυσαερίων (αντιστέκονται στην οξείδωση σε υψηλές θερμοκρασίες και στην όξινη στάχτη).

- Αεροδιαστημική & Άμυνα: Συστατικά του κινητήρα και οι ακροφύσια των πυραύλων (αντέχει υψηλές θερμοκρασίες και επιθετικά καύσιμα).

7Προσαρμογή και υπηρεσίες προστιθέμενης αξίας

Για να ικανοποιηθούν οι διαφορετικές ανάγκες του έργου, οι ακόλουθες προσαρμογές είναι διαθέσιμες για αυτή τη στρογγυλή μπάρα Hastelloy C276:

- Τμήμα κοπής: οποιοδήποτε μήκος (από μικρά τμήματα έως πλήρους μήκους ράβδους) μέσω πριονιστικής πριονίσεως ή κοπής πλάσματος (δεν υπάρχει ελάχιστη ποσότητα παραγγελίας για τις τυποποιημένες διαμέτρους).

- Επεξεργασία επιφάνειας: παρασκευή, παθητικοποίηση ή άλεση (για απαιτήσεις στενής τραχύτητας επιφάνειας, π.χ. Ra ≤0,8μm).

- Θερμική επεξεργασία: Αναψύκλωση (προτύπου), αναψύκλωση διαλύματος ή αφαίρεση στρες (ανάλογα με τις προδιαγραφές του πελάτη).

- Πιστοποιητικά: Πιστοποιητικά δοκιμής εργοστασίου (MTC) σύμφωνα με το πρότυπο EN 10204 (3.1B ή 3.2), συμμόρφωση με το πρότυπο NACE MR0175/ISO 15156 (για εφαρμογές ξινών αερίων) και έγκριση FDA (για τη χημική επεξεργασία τροφίμων).

![]()

![]()

![]()

![]()

Συνιστώμενα προϊόντα