All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

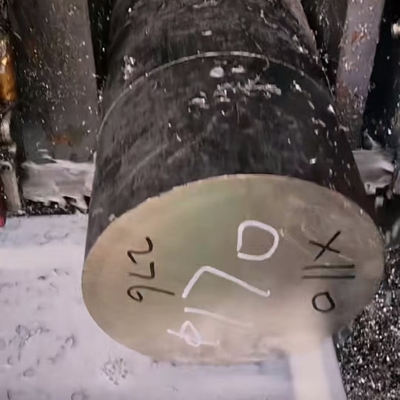

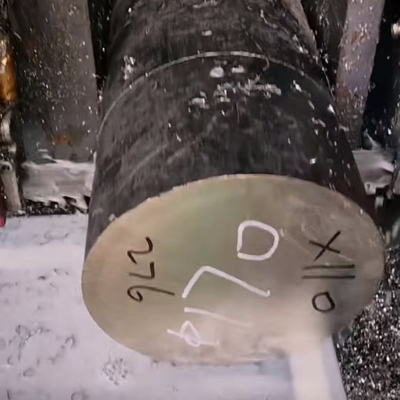

Hastelloy C276 Forged Round Bar Diameter 140 - 350mm Custom Cutting Any Length Alloy C276 Rod

Product Details

| Products | Nickel Alloy Plate | Grade | C276 |

|---|---|---|---|

| Diameter | 6 - 350mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black , Bright |

| Highlight | Hastelloy C276 forged round bar,Nickel alloy C276 rod,Custom cut Hastelloy C276 bar |

||

Product Description

Hastelloy C276 Forged Round Bar Diameter 140 - 350mm Custom Cutting Any Length Alloy C276 Rod

Quick Informations

| Grade | Hastelloy C276 / 2.4819 | Shape | Round Bar |

| Diameter | 6.0 - 350mm | Type | Hot rolled , forged |

| Length | Custom Cutting any length as request | Certificate | EN 10204-3.1 |

More Specification Informations

| Products Name | Hastelloy C276 Round Bar / Rod |

| Diameter | 6.0 - 350mm |

| Length | custom cutting any length as request |

| Surface | Black , bright |

| Brand | DELTA |

| Service | cutting |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

1. Core Specifications (140-350mm Forged Round Bar)

The dimensions and key parameters of this Hastelloy C276 round bar are optimized for heavy-duty industrial use, balancing strength and machinability.

| Parameter | Specification |

|---|---|

| Product Form | Forged round bar (hot-forged for enhanced density and grain structure) |

| Diameter Range | 140mm – 350mm (forged to tight dimensional tolerance; custom diameters available on request) |

| Length | Custom cutting available (any length, e.g., 100mm, 500mm, 1000mm, up to 6000mm; no minimum length restriction) |

| Forging Process | Hot forging (temperature range: 1150°C – 1230°C) followed by annealing for stress relief |

| Surface Finish | Forged surface (as-forged: slight oxidation layer) or pickled surface (optional, for corrosion resistance enhancement) |

| Tolerance (Diameter) | ASTM A480/A480M: ±0.5mm for diameters ≤200mm; ±0.8mm for diameters >200mm |

| Tolerance (Length) | Custom-cut length tolerance: ±1mm (standard) or ±0.5mm (precision cutting) |

2. Chemical Composition

Hastelloy C276’s exceptional corrosion resistance stems from its precisely balanced alloying elements, with low carbon and silicon content to prevent carbide precipitation (a common cause of intergranular corrosion).

| Element | Content Range (%) | Key Function |

|---|---|---|

| Nickel (Ni) | 56.0 min | Base metal; provides ductility and resistance to reducing environments |

| Molybdenum (Mo) | 15.0 – 17.0 | Enhances resistance to pitting, crevice corrosion, and sulfuric acid |

| Chromium (Cr) | 14.5 – 16.5 | Boosts oxidation resistance and resistance to oxidizing acids (e.g., nitric acid) |

| Iron (Fe) | 4.0 – 7.0 | Improves mechanical strength and forging workability |

| Tungsten (W) | 3.0 – 4.5 | Synergizes with Mo to enhance pitting corrosion resistance in chloride-rich media |

| Cobalt (Co) | 2.5 max | Controls alloy ductility and reduces brittleness |

| Carbon (C) | 0.01 max | Minimizes carbide formation (critical for weldability) |

| Silicon (Si) | 0.08 max | Prevents oxidation during high-temperature processing |

| Phosphorus (P) | 0.04 max | Limits impurities to avoid brittleness |

| Sulfur (S) | 0.03 max | Reduces hot cracking risk during forging and welding |

3. Mechanical & Corrosion Performance

This alloy excels in both mechanical strength and corrosion resistance, making it suitable for load-bearing components in aggressive environments.

3.1 Mechanical Properties (Annealed Condition)

| Property | Value (Typical) |

|---|---|

| Tensile Strength (σb) | ≥690 MPa |

| Yield Strength (σ0.2) | ≥310 MPa |

| Elongation (δ) | ≥40% (in 50mm gauge length) |

| Hardness (HB) | ≤210 |

| Impact Toughness (Charpy V-notch) | ≥100 J (at room temperature) |

| Maximum Service Temperature | 1093°C (short-term); 649°C (long-term, for continuous oxidation resistance) |

3.2 Corrosion Resistance

Hastelloy C276 is renowned as one of the most corrosion-resistant alloys globally, withstanding:

- Reducing acids: Sulfuric acid (up to 90% concentration), hydrochloric acid (dilute to moderate concentrations), and phosphoric acid.

- Oxidizing acids: Nitric acid (dilute), chromic acid, and mixed acids (e.g., acid rain, chemical process streams).

- Chloride-rich media: Seawater, brines, and chloride solutions (resists pitting and crevice corrosion—critical for marine and offshore applications).

- High-temperature environments: Resists oxidation and sulfidation in flue gases, incinerators, and petrochemical reactors.

Key Advantage: Unlike many stainless steels, it does not require post-weld heat treatment (PWHT) to maintain corrosion resistance, simplifying fabrication.

4. Manufacturing & Quality Standards

Hastelloy C276 forged round bars adhere to strict international standards to ensure consistency and reliability.

| Standard Category | Relevant Standards |

|---|---|

| Chemical Composition | ASTM B574, ASME SB574, DIN EN 10095 |

| Forging & Dimensional | ASTM A480/A480M (flatness/tolerance), ISO 898-6 (forging quality) |

| Mechanical Properties | ASTM B574, ASME SB574, BS 3074 (Part NA16) |

| Testing Requirements | - Non-destructive testing (NDT): Ultrasonic testing (UT) per ASTM A609 (100% coverage for defects) - Chemical analysis: Spectrometric testing - Mechanical testing: Tensile, hardness, and impact tests (per lot) |

| Surface Quality | ASTM A788 (for pickled surface) or ASTM A967 (passivation, optional) |

5. Equivalent Grades

Hastelloy C276 is marketed under different designations globally; these grades are chemically and performance-equivalent:

| Standard/Region | Equivalent Grade |

|---|---|

| ASTM/ASME (USA) | UNS N10276, Alloy C276 |

| DIN EN (Europe) | W. Nr. 2.4819 |

| BS (UK) | NA16 |

| JIS (Japan) | NW 276 |

| GB (China) | NS334 |

| ISO | NiMo16Cr15W (ISO 15156-3) |

Note: While these grades are interchangeable in most applications, always confirm compliance with project-specific standards (e.g., ASME BPVC for pressure vessels).

6. Applications

The 140-350mm diameter Hastelloy C276 forged round bar—with its custom length option—is ideal for large, heavy-duty components requiring both strength and corrosion resistance. Key applications include:

- Petrochemical & Refining: Reactors, pressure vessels, and heat exchanger tubes (resists sulfuric acid and hydrogen sulfide).

- Marine & Offshore: Propeller shafts, valve stems, and seawater handling components (withstands seawater corrosion and biofouling).

- Chemical Processing: Pumps, valves, and agitators for acid production (e.g., sulfuric, hydrochloric, and nitric acid plants).

- Waste Incineration: Furnace liners and flue gas ducts (resists high-temperature oxidation and acidic ash).

- Aerospace & Defense: Engine components and rocket nozzles (tolerates high temperatures and aggressive fuels).

7. Customization & Value-Added Services

To meet diverse project needs, the following customizations are available for this Hastelloy C276 round bar:

- Length Cutting: Any length (from short segments to full-length bars) via precision sawing or plasma cutting (no minimum order quantity for standard diameters).

- Surface Treatment: Pickling, passivation, or grinding (for tight surface roughness requirements, e.g., Ra ≤0.8μm).

- Heat Treatment: Annealing (standard), solution annealing, or stress relieving (per customer specifications).

- Certifications: Mill test certificates (MTC) per EN 10204 (3.1B or 3.2), NACE MR0175/ISO 15156 compliance (for sour gas applications), and FDA approval (for food-grade chemical processing).

![]()

![]()

![]()

![]()

Recommended Products