Alle producten

-

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

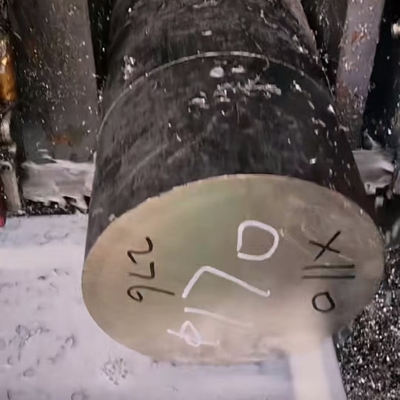

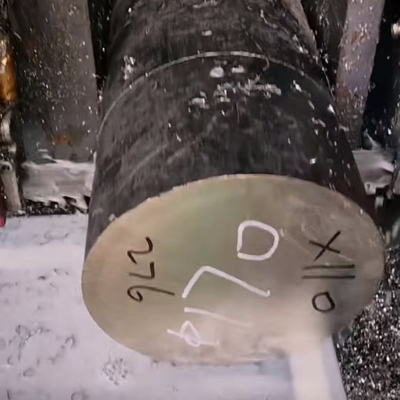

Hastelloy C276 gesmeed ronde staaf Diameter 140 - 350 mm Custom snijden van elke lengte legering C276 staaf

Productdetails

| Producten | Platen van nikkellegering | Cijfer | c276 |

|---|---|---|---|

| Diameter | 6 - 350 mm | Lengte | op aanvraag op maat gesneden |

| Standaard | Astm en | Dienst | Snij |

| Laadpoort | Shanghai -haven | Oppervlak | Zwart, helder. |

| Markeren | Hastelloy C276 forged round bar,Nickel alloy C276 rod,Custom cut Hastelloy C276 bar |

||

Productomschrijving

Hastelloy C276 gesmeed ronde staaf Diameter 140 - 350 mm Custom snijden van elke lengte legering C276 staaf

Snelle informatie

| Graad | Hastelloy C276 / 2.4819 | Vorm | Ronde balk |

| Diameter | 6.0 - 350 mm | Type | Warmgewalst, gesmeed |

| Lange | Op maat gesneden | Certificaat | EN 10204-3.1 |

Meer informatie over de specificaties

| Naam van de producten | Hastelloy C276 Ronde staaf / staaf |

| Diameter | 6.0 - 350 mm |

| Lange | op aanvraag op maat gesneden |

| Oppervlakte | Zwart, helder. |

| Merken | DELTA |

| Diensten | snijden |

| MOQ | 2 kg |

| Andere soorten | Ronde staaf, strip, spoel, buis, plaat, plaat, draad, enz. |

| Verpakking | waterdicht papier en houten pallets, houten doos |

| Laadhaven | haven van Shanghai |

| Prijsduur | EXW, FOB, CIF, CFR |

| Leveringstermijn | binnen 12 dagen |

1. Kernspecificaties (140-350 mm gesmeed rond staaf)

De afmetingen en de belangrijkste parameters van deze Hastelloy C276-ronde staaf zijn geoptimaliseerd voor zwaar industrieel gebruik, balanssterkte en bewerkbaarheid.

| Parameter | Specificatie |

|---|---|

| Productvorm | met een gewicht van niet meer dan 50 g/m2 |

| Diameters | 140 mm 350 mm (gesmeed met een strakke afmetingsverhouding; op aanvraag beschikbaar op maat gemaakte diameters) |

| Lange | Beschikbaar op maat gesneden (alle lengtes, bv. 100 mm, 500 mm, 1000 mm, tot 6000 mm; geen beperking van de minimumlengte) |

| Vervaardigingsproces | Warm smeden (temperatuurbereik: 1150°C ∼ 1230°C) gevolgd door gloeien om de spanning te verminderen |

| Oppervlakte afwerking | gesmeed oppervlak (als gesmeed: lichte oxidatieschaal) of gepekeld oppervlak (optioneel, ter verbetering van de corrosiebestendigheid) |

| Tolerantie (diameter) | ASTM A480/A480M: ±0,5 mm voor diameters ≤ 200 mm; ±0,8 mm voor diameters > 200 mm |

| Tolerantie (lengte) | Voor de afmeting op maat: ±1 mm (standaard) of ±0,5 mm (precisie) |

2Chemische samenstelling

De uitzonderlijke corrosiebestendigheid van Hastelloy C276 is te danken aan de nauwkeurig gebalanceerde legeringselementen.met een laag koolstof- en siliciumgehalte om het neerslaan van carbide te voorkomen (een veel voorkomende oorzaak van intergranulaire corrosie).

| Elementen | Inhoudsgroep (%) | Belangrijkste functie |

|---|---|---|

| Nikkel (Ni) | 56.0 min | Basis metaal; biedt ductiliteit en weerstand tegen reducerende omgevingen |

| Molybdeen (Mo) | 15.0 ¢ 17.0 | Verbetert de weerstand tegen pittings, spleetcorrosie en zwavelzuur |

| Chroom (Cr) | 14.5 ¢ 16.5 | Verhoogt de oxidatieweerstand en de weerstand tegen oxiderende zuren (bijv. stikstofzuur) |

| IJzer (Fe) | 4.0 ¢ 7.0 | Verbetert de mechanische sterkte en de bewerkbaarheid van het smeden |

| wolfraam (W) | 3.0 ¢ 4.5 | Synergieën met Mo om de corrosieweerstand tegen pitting in chloorrijke media te verbeteren |

| Cobalt (Co) | 2.5 max | Controles legering ductiliteit en vermindert broosheid |

| Koolstof (C) | 0.01 max. | Minimaliseert de vorming van carbide (kritisch voor lasbaarheid) |

| Silicium (Si) | 0.08 max. | Vermijdt oxidatie bij verwerking bij hoge temperatuur |

| Fosfor (P) | 0.04 max. | Beperk onzuiverheden om broosheid te voorkomen |

| Zwavel (S) | 0.03 max. | Vermindert het risico op warm kraken tijdens smeden en lassen |

3. Mechanische en corrosieprestaties

Deze legering heeft een uitstekende mechanische sterkte en corrosiebestendigheid, waardoor deze geschikt is voor dragende onderdelen in agressieve omgevingen.

3.1 Mechanische eigenschappen (gebrand)

| Vastgoed | Waarde (typisch) |

|---|---|

| Treksterkte (σb) | ≥ 690 MPa |

| Kracht van het vermogen (σ0,2) | ≥ 310 MPa |

| Verlenging (δ) | ≥ 40% (in 50 mm gauge lengte) |

| Hardheid (HB) | ≤ 210 |

| Schokhardheid (Charpy V-notch) | ≥ 100 J (bij kamertemperatuur) |

| Maximale bedieningstemperatuur | 1093°C (op korte termijn); 649°C (op lange termijn, voor continue oxidatiebestendigheid) |

3.2 Corrosiebestendigheid

Hastelloy C276 is wereldwijd bekend als een van de meest corrosiebestendige legeringen.

- Reductiezuren: zwavelzuur (tot 90% concentratie), zoutzuur (verdund tot matige concentratie) en fosforzuur.

- Oxiderende zuren: stikstofzuur (verdund), chromzuur en gemengde zuren (bijv. zure regen, chemische processtromen).

- Chloride-rijke media: zeewater, pekelwater en chlorideoplossingen (weerstand bieden aan corrosie door putten en spleten) - cruciaal voor marine en offshore toepassingen.

- Hoge temperatuuromgevingen: bestand tegen oxidatie en sulfidatie in rookgassen, verbrandingsinstallaties en petrochemische reactoren.

Belangrijkste voordeel: In tegenstelling tot veel roestvrij staal vereist het geen warmtebehandeling na las om de corrosiebestendigheid te behouden, waardoor de fabricage vereenvoudigd wordt.

4. Productie en kwaliteitsnormen

Hastelloy C276 gesmeed ronde staven voldoen aan strenge internationale normen om consistentie en betrouwbaarheid te garanderen.

| Standaard categorie | Relevante normen |

|---|---|

| Chemische samenstelling | ASTM B574, ASME SB574, DIN EN 10095 |

| Vervaardiging en afmetingen | ASTM A480/A480M (vlakte/tolerantie), ISO 898-6 (smeedkwaliteit) |

| Mechanische eigenschappen | ASTM B574, ASME SB574, BS 3074 (deel NA16) |

| Testvereisten | - Niet-destructieve test (NDT): Ultrasone test (UT) per ASTM A609 (100% dekking voor gebreken) - Chemische analyse: spectrometrische tests - Mechanische tests: trek-, hardheid- en slagtests (per partij) |

| Oppervlakte kwaliteit | ASTM A788 (voor gepekelde oppervlakken) of ASTM A967 (passivatie, optioneel) |

5. Gelijkwaardige graden

Hastelloy C276 wordt wereldwijd onder verschillende benamingen op de markt gebracht; deze soorten zijn chemisch en prestatie-equivalent:

| Standaard/regio | Gelijkwaardige graad |

|---|---|

| ASTM/ASME (VS) | UNS N10276, legering C276 |

| DIN EN (Europa) | W. nr. 2.4819 |

| BS (Verenigd Koninkrijk) | NA16 |

| JIS (Japan) | NW 276 |

| GB (China) | NS334 |

| ISO | NiMo16Cr15W (ISO 15156-3) |

Opmerking: Hoewel deze kwaliteiten in de meeste toepassingen uitwisselbaar zijn, moet u altijd de naleving van project-specifieke normen bevestigen (bijv. ASME BPVC voor drukvaten).

6. Toepassingen

De 140-350 mm doorsnede Hastelloy C276 gesmeed ronde staaf met aangepaste lengte is ideaal voor grote, zware componenten die zowel sterkte als corrosiebestendigheid vereisen.Belangrijkste toepassingen zijn::

- Petrochemie en raffinage: Reactors, drukvaten en warmtewisselaars (weerstand bieden aan zwavelzuur en waterstofsulfide).

- Marine & Offshore: schroefschachten, klepstammen en onderdelen voor het behandelen van zeewater (weerstand biedt aan corrosie en biofouling door zeewater).

- Chemische verwerking: pompen, kleppen en roermachines voor zuurproductie (bijv. zwavelzuur-, zout- en stikzuurinstallaties).

- Afvalverbranding: Ovenvoeringen en rookgasleidingen (weerstand bieden aan hoge temperatuur oxidatie en zure as).

- Luchtvaart en defensie: motorcomponenten en raketstukken (tolereert hoge temperaturen en agressieve brandstoffen).

7Aanpassing en toegevoegde waarde diensten

Om aan de verschillende behoeften van het project te voldoen, zijn de volgende aanpassingen beschikbaar voor deze Hastelloy C276 ronde staaf:

- Lange snijding: elke lengte (van korte segmenten tot full-length staven) met behulp van precisiezaag of plasmasnijden (geen minimale bestelhoeveelheid voor standaarddiameter).

- Oppervlaktebehandeling: pickelen, passiveren of slijpen (voor strakke oppervlakkrapte, bijvoorbeeld Ra ≤ 0,8 μm).

- Warmtebehandeling: gloeien (standaard), oplossing gloeien of spanningsverlichting (per specificatie van de klant).

- Certificeringen: MTC-certificaten (Mill Test Certificates) volgens EN 10204 (3.1B of 3.2), NACE MR0175/ISO 15156-naleving (voor toepassingen met zure gassen) en FDA-goedkeuring (voor chemische verwerking van levensmiddelen).

![]()

![]()

![]()

![]()

Geadviseerde Producten