Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

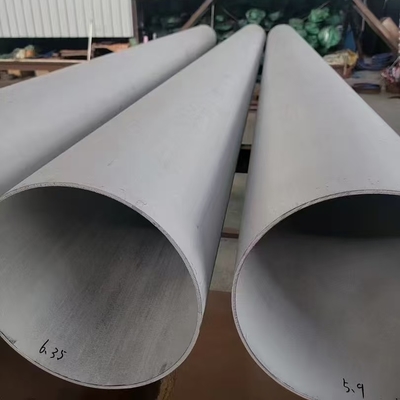

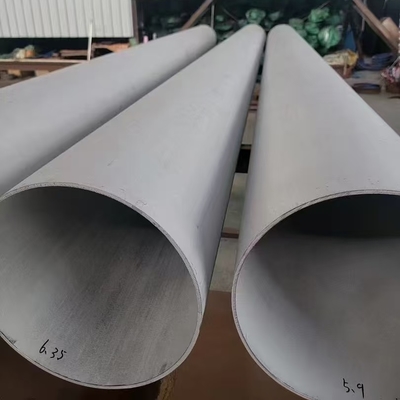

UNS S31703 / Σωλήνας από ανοξείδωτο χάλυβα κράματος 317L SS Σωλήνας ASTM A312 Με καλή αντοχή στη διάβρωση 3/5000

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | 309S |

| Ποσότητα παραγγελίας min | 1000 κιλά |

| Τιμή | 5.2 - 6.5 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 4 τόνοι την εβδομάδα |

Λεπτομέρειες

| Προϊόντα | Σωλήνας από ανοξείδωτο χάλυβα | Βαθμός | 317L |

|---|---|---|---|

| Διάμετρος | DN10 - DN400 | Μήκος | 6m ή προσαρμοσμένη κοπή οποιουδήποτε μήκους ως αίτημα |

| Πρότυπο | Astm en | Υπηρεσία | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Πάχος | 4.0 - 50.0mm |

| Επισημαίνω | Σωλήνας από ανοξείδωτο χάλυβα κράματος 317L,Σωλήνας ανθεκτικός στη διάβρωση ASTM A312,Πύλη από ανοξείδωτο χάλυβα UNS S31703 |

||

Περιγραφή προϊόντων

UNS S31703 / Σωλήνας από ανοξείδωτο χάλυβα κράματος 317L SS Σωλήνας ASTM A312 Με καλή αντοχή στη διάβρωση 3/5000

Προδιαγραφές προϊόντων

| Όνομα προϊόντων | Σωλήνας χωρίς ραφή από ανοξείδωτο χάλυβα 317L |

Βαθμός: |

304 304L 304LN 304H 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 2550 S32760 904L 254SMO και ισοδύναμος βαθμός στο πρότυπο GB JIS EN DIN |

| Πρότυπα: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Μέγεθος: | ND5 - DN400 |

| Μήκος: | Μήκος 6m ή κοπή οποιουδήποτε μήκους κατόπιν αιτήματος |

| Εφαρμογές: | μεταφορά υγρών και αερίων, δομή, λέβητας, εναλλάκτης θερμότητας, υπερθερμαντήρας |

UNS S31703 / Σωλήνας από ανοξείδωτο χάλυβα κράματος 317L SS Σωλήνας ASTM A312 Με καλή αντοχή στη διάβρωση

Ο σωλήνας από ανοξείδωτο χάλυβα UNS S31703 (γνωστός και ως κράμα 317L), που κατασκευάζεται σύμφωνα με το πρότυπο ASTM A312, είναι ένα προϊόν από ανοξείδωτο χάλυβα αυξημένης ποιότητας, γνωστό για την εξαιρετική του αντοχή στη διάβρωση, τη μηχανική σταθερότητα και την ευελιξία του. Χρησιμοποιείται ευρέως σε σκληρά βιομηχανικά περιβάλλοντα όπου η αντοχή σε χημικές επιθέσεις, υψηλές θερμοκρασίες και οξείδωση είναι κρίσιμη. Ακολουθεί μια ολοκληρωμένη επισκόπηση των παραμέτρων, της απόδοσης, της διαδικασίας παραγωγής, των προτύπων, των πλεονεκτημάτων, των ισοδύναμων βαθμών και των εφαρμογών του.

1. Βασική χημική σύνθεση (Παράμετροι)

Η μοναδική αντοχή στη διάβρωση και οι μηχανικές ιδιότητες του UNS S31703/317L προέρχονται από την ακριβή χημική του σύνθεση, με το μολυβδαίνιο (Mo) να είναι το βασικό στοιχείο κράματος που ενισχύει την αντοχή στην διάβρωση με κοιλώματα και ρωγμές (ένας κοινός τρόπος αποτυχίας σε περιβάλλοντα πλούσια σε χλωριούχα). Η σύνθεση συμμορφώνεται με τα ASTM A312 και προδιαγραφές UNS S31703:

| Στοιχείο | Εύρος περιεκτικότητας (%) | Ρόλος |

|---|---|---|

| Άνθρακας (C) | ≤ 0,03 | Η χαμηλή περιεκτικότητα σε άνθρακα αποτρέπει την καθίζηση καρβιδίου κατά τη συγκόλληση, αποφεύγοντας τη διακοκκώδη διάβρωση. |

| Χρώμιο (Cr) | 18,00 - 20,00 | Σχηματίζει μια πυκνή, προσκολλητική μεμβράνη οξειδίου του χρωμίου (Cr₂O₃), αντιστέκεται στη γενική οξείδωση και διάβρωση. |

| Νικέλιο (Ni) | 11,00 - 15,00 | Σταθεροποιεί την ωστενιτική κρυσταλλική δομή, βελτιώνοντας την ολκιμότητα και την ανθεκτικότητα (ειδικά σε χαμηλές θερμοκρασίες). |

| Μολυβδαίνιο (Mo) | 3,00 - 4,00 | Ενισχύει την αντοχή στη διάβρωση με κοιλώματα, ρωγμές και την επίθεση θειικού οξέος (κρίσιμο για θαλάσσιες ή χημικές εφαρμογές). |

| Μαγγάνιο (Mn) | ≤ 2,00 | Βελτιώνει την εργασιμότητα και την αντοχή χωρίς συμβιβασμούς στην ολκιμότητα. |

| Πυρίτιο (Si) | ≤ 1,00 | Βοηθά στην αποξείδωση κατά την τήξη και ενισχύει την αντοχή στην οξείδωση σε υψηλές θερμοκρασίες. |

| Φώσφορος (P) | ≤ 0,045 | Ελέγχεται για την ελαχιστοποίηση της ευθραυστότητας και την εξασφάλιση της συγκολλησιμότητας. |

| Θείο (S) | ≤ 0,030 | Μειώνεται για την αποφυγή θερμών ρωγμών κατά την κατασκευή και τη διατήρηση της αντοχής στη διάβρωση. |

| Άζωτο (N) | ≤ 0,10 | Συμπληρωματικό στοιχείο για την ενίσχυση της αντοχής χωρίς θυσία της ολκιμότητας. |

2. Μηχανική απόδοση

Ο σωλήνας από ανοξείδωτο χάλυβα UNS S31703/317L παρουσιάζει ισορροπημένες μηχανικές ιδιότητες, καθιστώντας τον κατάλληλο τόσο για εφαρμογές αντοχής σε πίεση όσο και για δομικές εφαρμογές. Οι παρακάτω τιμές είναι τυπικές για σωλήνες στην κατάσταση ανόπτησης (κοινή κατάσταση παράδοσης) και πληρούν τις απαιτήσεις του ASTM A312:

| Μηχανική ιδιότητα | Προδιαγραφή (ASTM A312) | Τυπική τιμή | Συνθήκη δοκιμής |

|---|---|---|---|

| Αντοχή σε εφελκυσμό (σb) | ≥ 485 MPa (70 ksi) | 550 - 650 MPa | Θερμοκρασία δωματίου |

| Όριο διαρροής (σ0,2) | ≥ 170 MPa (25 ksi) | 200 - 300 MPa | Θερμοκρασία δωματίου |

| Επιμήκυνση (δ) | ≥ 35% | 40 - 45% | Μετά από θραύση (μήκος μετρητή 50 mm) |

| Σκληρότητα (Brinell, HB) | ≤ 217 | 180 - 210 | Ανόπτηση |

| Ανθεκτικότητα σε κρούση (Charpy) | ≥ 100 J | 120 - 150 J | -40°C (ανθεκτικότητα σε χαμηλή θερμοκρασία, χωρίς εύθραυστη θραύση) |

Απόδοση σε υψηλή θερμοκρασία: Διατηρεί καλή αντοχή και αντοχή στην οξείδωση έως και 870°C (1600°F). Για βραχυπρόθεσμη χρήση (π.χ., θερμική κυκλοφορία), μπορεί να αντέξει θερμοκρασίες έως και 980°C (1800°F) χωρίς σημαντική υποβάθμιση.

3. Διαδικασία παραγωγής

Η κατασκευή του σωλήνα από ανοξείδωτο χάλυβα UNS S31703/317L (ASTM A312) ακολουθεί αυστηρές διαδικασίες για να εξασφαλιστεί η ακρίβεια των διαστάσεων, η ποιότητα της επιφάνειας και η ακεραιότητα του υλικού. Τα βασικά βήματα είναι:

- Επιλογή πρώτης ύλης: Χρησιμοποιούνται χάλυβες ή πλινθώματα από ανοξείδωτο χάλυβα υψηλής καθαρότητας με σύνθεση UNS S31703, που επιθεωρούνται για χημική ομοιομορφία και ελαττώματα (π.χ., εγκλείσματα).

- Τήξη & Χύτευση: Τα πλινθώματα τήκονται μέσω ηλεκτρικού φούρνου τόξου (EAF) ή τήξης επαγωγής κενού (VIM) (για απαιτήσεις υψηλής καθαρότητας) για τον έλεγχο των ακαθαρσιών και στη συνέχεια χυτεύονται σε κενά σωλήνων χωρίς ραφή.

- Σχηματισμός σωλήνων χωρίς ραφή:

- Θερμή διάτρηση: Τα κενά θερμαίνονται στους 1100 - 1250°C και διατρυπώνται σε κοίλους σωλήνες χρησιμοποιώντας ένα μύλο στελέχους.

- Θερμή έλαση/εξώθηση: Οι σωλήνες κυλιούνται (μέσω συνεχούς μύλου σωλήνων) ή εξωθούνται για να επιτευχθεί η επιθυμητή εξωτερική διάμετρος (OD) και το πάχος τοιχώματος (WT).

- Ανόπτηση: Οι σωλήνες ανόπτονται στους 1010 - 1150°C, ακολουθούμενη από ταχεία απόσβεση νερού. Αυτό το βήμα μαλακώνει το υλικό, αποκαθιστά την ολκιμότητα και αναμορφώνει τη παθητική μεμβράνη οξειδίου (κρίσιμη για την αντοχή στη διάβρωση).

- Ψυχρή φινίρισμα (Προαιρετικό): Για εφαρμογές ακριβείας (π.χ., ιατρικές ή ημιαγωγών), οι σωλήνες υποβάλλονται σε ψυχρή έλξη ή ψυχρή έλαση για τη βελτίωση της ανοχής των διαστάσεων (π.χ., OD ±0,1 mm) και της ομαλότητας της επιφάνειας (Ra ≤ 0,8μm).

- Θερμική επεξεργασία για συγκολλημένους σωλήνες: Εάν παράγονται συγκολλημένοι σωλήνες ASTM A312 (π.χ., ERW - Ηλεκτρική συγκόλληση αντίστασης), απαιτείται μια διαδικασία ανόπτησης μετά τη συγκόλληση για την εξάλειψη της υπολειμματικής τάσης και την αποφυγή διακοκκώδους διάβρωσης.

- Επιθεώρηση & Δοκιμή:

- Μη καταστρεπτικές δοκιμές (NDT): Υπερηχητική δοκιμή (UT) για εσωτερικά ελαττώματα, δοκιμή ρευμάτων Eddy (ECT) για επιφανειακά ελαττώματα και υδροστατική δοκιμή (1,5× πίεση σχεδιασμού) για την επαλήθευση της στεγανότητας.

- Χημικές & Μηχανικές δοκιμές: Δειγματική ανάλυση για συμμόρφωση σύνθεσης και δοκιμές εφελκυσμού/κρούσης για επιβεβαίωση μηχανικών ιδιοτήτων.

- Επεξεργασία επιφάνειας: Οι σωλήνες μαρινάρονται (με νιτρικό-υδροφθορικό οξύ) για την αφαίρεση της κλίμακας και στη συνέχεια παθητικοποιούνται (με νιτρικό οξύ) για την ενίσχυση της ανθεκτικότητας της παθητικής μεμβράνης.

4. Εφαρμοστέα πρότυπα

Ο σωλήνας από ανοξείδωτο χάλυβα UNS S31703/317L κατασκευάζεται και επιθεωρείται σύμφωνα με τα παγκόσμια πρότυπα για να διασφαλιστεί η συμβατότητα με τις απαιτήσεις του κλάδου. Τα κύρια πρότυπα περιλαμβάνουν:

| Κωδικός προτύπου | Όνομα προτύπου | Πεδίο εφαρμογής |

|---|---|---|

| ASTM A312 | Τυπική προδιαγραφή για σωλήνες από ωστενιτικό ανοξείδωτο χάλυβα χωρίς ραφή, συγκολλημένους και βαρέως ψυχρής κατεργασίας | Καθορίζει διαστάσεις, χημική σύνθεση, μηχανικές ιδιότητες, μεθόδους δοκιμών και απαιτήσεις παράδοσης για σωλήνες που χρησιμοποιούνται σε συστήματα πίεσης. |

| UNS S31703 | Ενοποιημένο σύστημα αρίθμησης για μέταλλα και κράματα | Ταξινομεί το κράμα ως ωστενιτικό ανοξείδωτο χάλυβα χαμηλού άνθρακα που περιέχει μολυβδαίνιο. |

| ASME B36.19M | Σωλήνας από ανοξείδωτο χάλυβα (Μετρικός) | Καθορίζει ανοχές διαστάσεων (OD, WT, μήκος) για σωλήνες από ανοξείδωτο χάλυβα, συμπεριλαμβανομένου του 317L. |

| EN 10216-5 | Σωλήνες από χάλυβα χωρίς ραφή για σκοπούς πίεσης - Μέρος 5: Ωστενιτικοί ανοξείδωτοι χάλυβες | Ευρωπαϊκό πρότυπο ισοδύναμο με το ASTM A312, εφαρμόσιμο για σωλήνες στις αγορές της ΕΕ. |

| JIS G3459 | Σωλήνες και σωλήνες από ανοξείδωτο χάλυβα | Ιαπωνικό βιομηχανικό πρότυπο για σωλήνες από ανοξείδωτο χάλυβα, συμπεριλαμβανομένου του βαθμού 317L. |

5. Βασικά πλεονεκτήματα

Σε σύγκριση με τους συμβατικούς ωστενιτικούς ανοξείδωτους χάλυβες (π.χ., 304L, 316L), το UNS S31703/317L προσφέρει ξεχωριστά πλεονεκτήματα, ειδικά σε σκληρά περιβάλλοντα:

- Ανώτερη αντοχή στη διάβρωση: Η υψηλότερη περιεκτικότητα σε μολυβδαίνιο (3-4%) παρέχει εξαιρετική αντοχή στη διάβρωση με κοιλώματα, ρωγμές και ρωγμές λόγω καταπόνησης (SCC) σε μέσα πλούσια σε χλωριούχα (π.χ., θαλασσινό νερό, άλμη, ροές χημικής διεργασίας). Αντιστέκεται επίσης στην επίθεση από αραιό θειικό οξύ, φωσφορικό οξύ και οργανικά οξέα.

- Εξαιρετική συγκολλησιμότητα: Η χαμηλή περιεκτικότητα σε άνθρακα (≤0,03%) αποτρέπει την καθίζηση καρβιδίου στη ζώνη που επηρεάζεται από τη θερμότητα συγκόλλησης (HAZ), εξαλείφοντας τη διακοκκώδη διάβρωση χωρίς να απαιτείται θερμική επεξεργασία μετά τη συγκόλληση (PWHT) στις περισσότερες περιπτώσεις. Εφαρμόζονται κοινές μέθοδοι συγκόλλησης (TIG, MIG, SMAW).

- Ευρύ φάσμα θερμοκρασιών: Διατηρεί την ολκιμότητα και την αντοχή από κρυογονικές θερμοκρασίες (-270°C) έως υψηλές θερμοκρασίες (870°C), κατάλληλο τόσο για αποθήκευση σε χαμηλή θερμοκρασία όσο και για σωληνώσεις διεργασίας υψηλής θερμοκρασίας.

- Καλή μηχανική ισορροπία: Συνδυάζει υψηλή αντοχή σε εφελκυσμό με εξαιρετική ολκιμότητα, επιτρέποντας την εύκολη κατασκευή (κάμψη, φλάντζα, κοπή) χωρίς ρωγμές.

- Μεγάλη διάρκεια ζωής: Η σταθερή παθητική μεμβράνη οξειδίου και η αντοχή στην περιβαλλοντική υποβάθμιση μειώνουν το κόστος συντήρησης και παρατείνουν τη διάρκεια ζωής του σωλήνα σε επιθετικές εφαρμογές.

6. Ισοδύναμοι βαθμοί

Το UNS S31703/317L έχει ισοδύναμους βαθμούς σε μεγάλα παγκόσμια πρότυπα, διασφαλίζοντας την εναλλαξιμότητα σε διεθνή έργα:

| Περιοχή/Πρότυπο | Ισοδύναμος βαθμός | Σημειώσεις |

|---|---|---|

| ΗΠΑ | UNS S31703, ASTM A312 317L | Πρωτεύων βαθμός. Το UNS S31703 είναι η ονομασία του υλικού, ενώ το ASTM A312 είναι το πρότυπο του σωλήνα. |

| Ευρώπη | EN 1.4438, EN 10216-5 1.4438 | Η περιεκτικότητα σε μολυβδαίνιο (3-4%) ταιριάζει με το UNS S31703. χρησιμοποιείται σε βιομηχανικές εφαρμογές της ΕΕ. |

| Ιαπωνία | JIS G3459 SUS317L | Συμμορφώνεται με τις προδιαγραφές JIS. ισοδύναμο στη σύνθεση και την απόδοση. |

| Κίνα | GB/T 14976 022Cr19Ni13Mo3 | Εθνικό ισοδύναμο πρότυπο. Το “022” υποδεικνύει χαμηλό άνθρακα (≤0,03%). |

| Διεθνές | ISO 15510 X2CrNiMo18-13-3 | Ονομασία ISO για ωστενιτικό ανοξείδωτο χάλυβα χαμηλού άνθρακα, ενισχυμένο με μολυβδαίνιο. |

7. Τυπικές εφαρμογές

Λόγω της ισχυρής του απόδοσης, ο σωλήνας από ανοξείδωτο χάλυβα UNS S31703/317L χρησιμοποιείται ευρέως σε βιομηχανίες που απαιτούν υψηλή αντοχή στη διάβρωση και αξιοπιστία:

- Χημική επεξεργασία: Σωληνώσεις για το χειρισμό θειικού οξέος, φωσφορικού οξέος, οργανικών οξέων και χημικών διαλυτών (π.χ., σε εργοστάσια λιπασμάτων, φαρμακευτική παραγωγή, διυλιστήρια πετροχημικών).

- Θαλάσσια & Υπεράκτια: Συστήματα ψύξης θαλασσινού νερού, σωληνώσεις υπεράκτιων πλατφορμών, μονάδες αφαλάτωσης και σωληνώσεις πλοίων (αντιστέκεται στη διάβρωση και τη διάβρωση που προκαλείται από το θαλασσινό νερό).

- Τρόφιμα & Ποτά: Σωληνώσεις για όξινα τρόφιμα (π.χ., χυμοί εσπεριδοειδών, τουρσιά) και διαδικασίες καθαρισμού σε υψηλή θερμοκρασία (CIP - Clean-in-Place), καθώς είναι μη τοξικό και εύκολο στην απολύμανση.

- Φαρμακευτική & Βιοτεχνολογία: Υγιεινές σωληνώσεις για τη σύνθεση φαρμάκων, την παραγωγή εμβολίων και συστήματα καθαρού νερού (συμμορφώνεται με τις απαιτήσεις του FDA για την ασφάλεια των υλικών).

- Παραγωγή ενέργειας: Σωληνώσεις υψηλής θερμοκρασίας σε εργοστάσια παραγωγής ενέργειας από ορυκτά καύσιμα (συστήματα αποθείωσης καυσαερίων) και πυρηνικούς σταθμούς παραγωγής ενέργειας (δευτερεύοντες βρόχοι ψύξης, όπου η αντοχή στη διάβρωση είναι κρίσιμη).

- Επεξεργασία λυμάτων: Σωληνώσεις για διαβρωτικές ροές λυμάτων (π.χ., βιομηχανικά απόβλητα με υψηλή περιεκτικότητα σε χλωριούχα ή θειικά) και συστήματα αναερόβιας πέψης.

- Αεροδιαστημική & Άμυνα: Κρυογονικές σωληνώσεις για την αποθήκευση καυσίμων πυραύλων (υγρό οξυγόνο, υγρό άζωτο) και αγωγοί υψηλής θερμοκρασίας σε κινητήρες αεροσκαφών.

![]()

![]()

![]()

![]()

Συνιστώμενα προϊόντα