-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

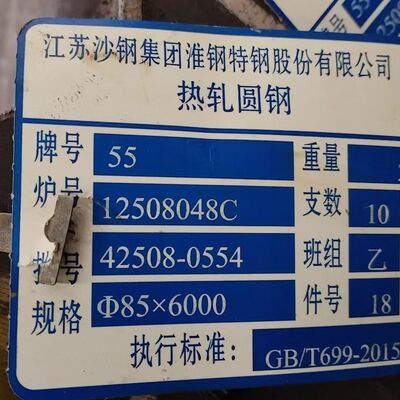

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

DIN 1.7225 (42CrMo4) Alloy Structural Steel Round Bar – Quenched and Tempered

| Place of Origin | China |

|---|---|

| Nombre de la marca | DELTA |

| Certificación | ISO |

| Model Number | Alloy Steel |

| Minimum Order Quantity | 1 Ton |

| Precio | 800 - 1200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Products Name | Alloy Steel Round Bar | Diameter | 10 - 450mm |

|---|---|---|---|

| Length | 6m | Tech | Hot rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

Products Specification

|

Products Name |

Alloy Steel Round Bar |

|

Diameter |

20 - 350 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo ,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,25Cr2MoVA,5CrMnMo ,38CrMoAl, 30CrMnSiA,B16,31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Product Overview

Key Features & Benefits

- ✅ High Strength-to-Toughness Ratio: Yield strength up to 930 MPa, tensile strength 1080–1250 MPa

- ✅ Excellent Fatigue Resistance: Ideal for cyclic loading (e.g., crankshafts, axles, gears)

- ✅ Good Hardenability: Deep through-hardening due to Cr and Mo content—suitable for large cross-sections

- ✅ Machinable in Q+T Condition: Better than fully hardened tool steels; compatible with standard HSS/carbide tools

- ✅ Weldable with Preheat: Can be welded using low-hydrogen procedures (preheat 200–300°C recommended)

- ✅ Traceable & Certified: Full EN 10204 3.1 mill test reports with chemical and mechanical data

Chemical Composition (Typical % – DIN EN 10083-3)

| Element | C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|---|

| Range | 0.38–0.45 | 0.17–0.37 | 0.60–0.90 | ≤0.025 | ≤0.025 | 0.90–1.20 | 0.15–0.25 |

Mechanical Properties After Quenching & Tempering

| Tempering Temp. | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Impact Energy (Charpy V, J @ -20°C) |

|---|---|---|---|---|---|

| 500°C | 1200–1250 | ≥1080 | ≥10 | 341–363 | ≥47 |

| 550°C | 1100–1180 | ≥980 | ≥11 | 302–341 | ≥54 |

| 600°C | 1000–1080 | ≥900 | ≥12 | 269–302 | ≥63 |

| 650°C | 930–1000 | ≥785 | ≥13 | 241–269 | ≥78 |

Properties vary slightly based on bar diameter. Larger diameters may show marginally lower core hardness due to quench severity limits.

Dimensional Range & Tolerances

| Parameter | Standard Offering |

|---|---|

| Diameter | 20 mm – 250 mm |

| Length | 3,000 mm – 6,000 mm (custom cuts available) |

| Straightness | ≤ 0.3 mm/m (standard), ≤ 0.15 mm/m (precision) |

| Diameter Tolerance | ±0.5% or per ISO h11 (as-rolled Q+T); precision ground options (h6/h7) available upon request |

| Surface Condition | Peeled, turned, or black (scale-free after shot blasting); optional precision grinding |

Common Applications

- Automotive: Crankshafts, camshafts, steering knuckles, drive axles

- Oil & Gas: Drill collars, downhole tools, valve stems

- Heavy Machinery: Excavator pins, hydraulic cylinders, gear shafts

- Aerospace: Landing gear components, actuator rods

- Industrial Equipment: High-torque couplings, spindle bars, forging dies

- Energy: Wind turbine main shafts, pump rotors

Heat Treatment Guidelines

- Stress Relieving: 600–650°C for 1–2 hours, air cool – to minimize distortion before final machining

- Induction Hardening: Surface hardening possible for wear-resistant journals (e.g., 55–60 HRC surface, tough core)

- Nitriding: Possible after final machining (tempering temp must exceed nitriding temp ~520°C)

Comparison: 42CrMo4 vs. Similar Grades

| Grade | Standard | Key Difference | Best For |

|---|---|---|---|

| 42CrMo4 | EN/DIN | Balanced Cr-Mo; excellent hardenability | High-strength structural parts |

| 4140 | AISI/SAE | Nearly identical; minor spec variations | North American machinery |

| 42CrMoS4 | EN | Higher sulfur (~0.020–0.040%) for free-machining | High-volume CNC parts (reduced tool wear) |

| 34CrNiMo6 | EN | Higher Ni content → superior toughness | Cryogenic or impact-critical uses |

Quality Assurance & Certification

- Produced under ISO 9001 and IATF 16949 (for automotive customers)

- Ultrasonic Testing (UT) available per SEP 1921 or ASTM A388 for internal soundness

- Magnetic Particle Inspection (MPI) for surface defect detection (optional)

- Full chemical analysis, tensile, impact, and hardness test reports included

- Batch traceability via unique heat number

Ordering Information

- Grade: DIN 1.7225 / 42CrMo4

- Heat treatment condition: Quenched & Tempered (state desired hardness or tempering temperature if critical)

- Diameter and length

- Surface finish: Black, peeled, turned, or precision ground

- Tolerance class (e.g., ISO h11, h9, or custom)

- Quantity and delivery terms (FOB, CIF, etc.)

- Certification level (EN 10204 2.2, 3.1, or 3.2)

Why Choose Our 42CrMo4 Q+T Round Bar?

- Consistent Performance: Tight control over chemistry and heat treatment ensures repeatable results

- Global Compliance: Meets European, American, and international standards

- Technical Support: Metallurgical engineers available for material selection and processing advice

- Sustainability: Produced with >80% recycled content; energy-efficient heat treatment lines