-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

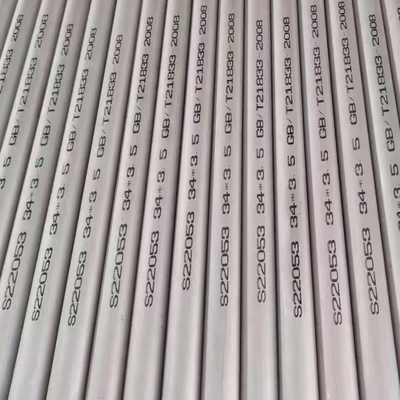

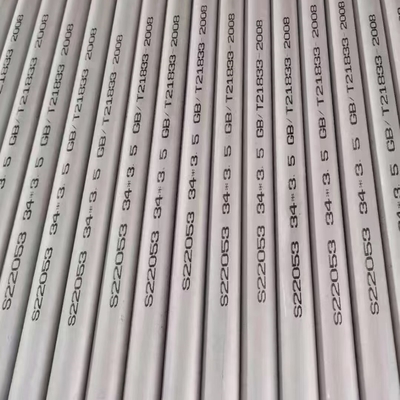

EN 1.4410 / 2507 / UNS S32750 Duplex Stainless Steel Pipe for Marine Engineering SS Pipes

| Products | Stainless Steel Seamless Pipe | Grade | S32750 / 2507 / 1.4410 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | EN 1.4410 duplex stainless steel pipe,2507 marine grade stainless steel pipe,UNS S32750 duplex steel pipe |

||

EN 1.4410 / 2507 / UNS S32750 Duplex Stainless Steel Pipe for Marine Engineering SS Pipes

Products Specification

| Products Name | Duplex 2507 Stainless Steel Seamless Pipe |

Grade: |

304 304L 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

Introduction

2507 duplex stainless steel (designated as EN 1.4410, UNS S32750, or F53) is a super duplex alloy combining ferritic and austenitic structures. It delivers exceptional mechanical strength and corrosion resistance, especially in aggressive marine environments. With high chromium (24–26%), molybdenum (3–5%), and nitrogen (0.24–0.32%) content, it outperforms standard austenitic steels (e.g., 316L) and common duplex grades (e.g., 2205) in chloride-rich settings like seawater systems, offshore platforms, and desalination plants.

1. Chemical Composition (wt%)

The optimized balance of key elements enhances pitting and stress corrosion resistance:

| Element | C | Cr | Ni | Mo | N | Mn | Si | S | P |

|---|---|---|---|---|---|---|---|---|---|

| Min | ≤0.03 | 24.0 | 6.0 | 3.0 | 0.24 | ≤1.2 | ≤0.80 | ≤0.02 | ≤0.035 |

| Max | 26.0 | 8.0 | 5.0 | 0.32 |

2. Mechanical Properties

Superior strength and ductility enable thinner pipe walls, reducing weight and cost:

| Property | Value | Unit |

|---|---|---|

| Tensile Strength (σb) | ≥730–795 | MPa |

| Yield Strength (σ0.2) | ≥550 | MPa |

| Elongation (δ) | ≥15–25 | % |

| Hardness | ≤290–310 | HV |

| Impact Energy (RT) | ≥74 | ft-lb |

| Thermal Expansion (20–100°C) | 13 × 10⁻⁶ | K⁻¹ |

3. Key Characteristics

-

Corrosion Resistance:

-

Immune to chloride-induced stress corrosion cracking (SCC), even in 2000 ppm Cl⁻ environments.

-

Superior to 904L in sulfuric acid with chlorides and to 316L in dilute hydrochloric acid.

-

-

Strength & Durability:

-

Yield strength ≥550 MPa (twice that of standard austenitic steels), suitable for high-pressure pipelines.

-

Low thermal expansion and high thermal conductivity reduce thermal stress.

-

-

Weldability:

-

Compatible with ER2594 filler metal and E2594 electrodes for crack-free joints.

-

-

Temperature Limits:

-

Avoid prolonged exposure >570°F (300°C) to prevent embrittlement.

-

4. Standards & Equivalent Grades

| Region | Standard | Grade |

|---|---|---|

| Europe | EN 1.4410 | X2CrNiMoN 25-7-4 |

| USA | UNS S32750 | ASTM A790/A789 |

| France | AFNOR Z3 CN 25.06 Az | ASME SA-240 |

| Japan | JIS G3463 | F53 |

5. Applications in Marine Engineering

-

Offshore Structures: Subsea pipelines, platform water injection systems, firefighting equipment.

-

Desalination Plants: High-pressure RO tubes, brine heaters.

-

Shipbuilding: Chemical tanker piping, ballast water systems.

-

Heat Exchangers: Seawater cooling systems due to biofouling resistance.

6. Export Packaging & Transportation

-

Packaging:

-

Ends capped with plastic protectors.

-

Bundled in woven bags or wooden crates (weather-resistant).

-

-

Transport:

-

Seaworthy containers with waterproof wrapping.

-

Shock-absorbent stacking to prevent surface damage during transit.

-

![]()

![]()

![]()

![]()

![]()