-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

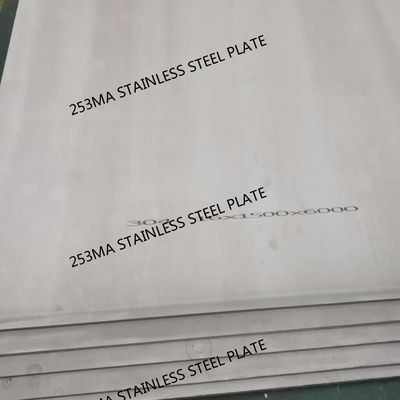

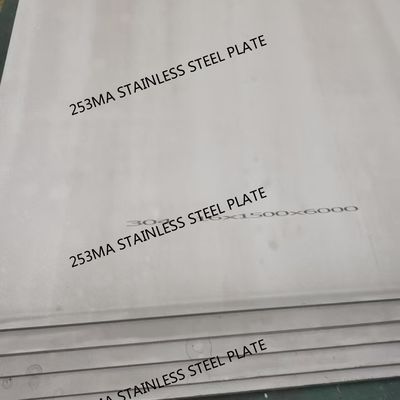

EN 1.4835 253MA Stainless Steel Plate High Chrome Nickel Alloy Hot Rolled For Industrial Heating Equipment

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 253ma / S30815 |

| Minimum Order Quantity | 500 kgs |

| Price | 1700- 2000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Plate | Grade | 253ma / S30815 |

|---|---|---|---|

| Thickness | 3.0 - 80.0mm | Width | 1500mm 1800mm 2000mm |

| Surface | NO.1 | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Industrial Heating Equipment Stainless Steel Plate,EN 1.4835 Stainless Steel Plate,253MA Stainless Steel Plate |

||

EN 1.4835 (253MA) Stainless Steel Plate High Chrome Nickel Alloy Hot Rolled Ideal for Industrial Heating Equipment

Products Specification

| Products Name | 253ma Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

PRODUCT INFORMATION: 253MA® (UNS S30815) STAINLESS STEEL PLATE

1. Material Grade:

253MA® (UNS S30815, EN 1.4835, ASTM A240/A480)

Registered Trademark of Outokumpu Stainless

2. Overview:

253MA® is a high-temperature austenitic stainless steel plate engineered for exceptional oxidation resistance, creep strength, and thermal stability in extreme environments up to 1150°C (2100°F). Its unique composition leverages rare earth elements (Cerium) to form a protective oxide layer under cyclic heating conditions.

3. Key Features & Benefits:

-

Superior Oxidation Resistance: Outperforms 309/S30900 and 310/S31000 grades at temperatures exceeding 1000°C (1832°F).

-

High Creep Strength: Maintains structural integrity under sustained stress at elevated temperatures.

-

Thermal Cycling Resistance: Resists spalling (scale peeling) during repeated heating/cooling cycles.

-

Nitrogen-Enhanced Strength: Higher ambient and high-temperature strength vs. standard austenitics.

-

Cost-Effective: Alternative to nickel alloys in many applications.

4. Chemical Composition (Typical wt%):

| Element | C | Si | Mn | Cr | Ni | N | Ce | P | S |

|---|---|---|---|---|---|---|---|---|---|

| % | 0.08 | 1.7 | 0.8 | 21.0 | 11.0 | 0.17 | 0.05 | 0.04 | 0.03 |

5. Mechanical Properties (Plate, Annealed Condition):

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | ≥600 MPa | ≥87,000 psi |

| Yield Strength (0.2%) | ≥310 MPa | ≥45,000 psi |

| Elongation (50mm) | ≥40% | ≥40% |

| Hardness (Brinell) | ≤217 HBW | ≤217 HBW |

6. Temperature Performance:

-

Continuous Service: Up to 1100°C (2012°F) in oxidizing atmospheres.

-

Max Intermittent Service: 1150°C (2100°F).

-

Scaling Resistance: Surpasses Type 310S above 1000°C (1832°F).

7. Applications:

-

Furnace components (radiant tubes, burners, muffles)

-

Cement/chemical plant kilns & heat exchangers

-

Thermal oxidizers & incinerators

-

Power generation boiler parts

-

Petrochemical cracking tubes

-

Heat treatment fixtures

8. Available Plate Specifications:

-

Thickness: 3.0mm – 100mm (0.12" – 4")

-

Widths: 1000mm – 2000mm (39" – 79")

-

Lengths: 2000mm – 6000mm (79" – 236")

-

Surface Finish: No.1 (Hot-rolled, annealed & descaled), 2B (Cold-rolled, annealed & pickled)

-

Standards: ASTM A240/480, ASME SA240, EN 10028-7

9. Fabrication Notes:

-

Welding: Use 253MA® filler (e.g., Sandvik 23.12.L). Low heat input recommended.

-

Hot Working: Forge at 1150–900°C (2102–1652°F).

-

Cold Working: Higher forces required than 304; intermediate annealing advised.

-

Machining: Similar to other austenitics; use positive rake tools, rigid setup.

10. Quality Certification:

Mill test certificates (MTC) per EN 10204 3.1/3.2 available. Compliant with PED 2014/68/EU.

![]()

![]()

![]()

![]()