Todos os Produtos

-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

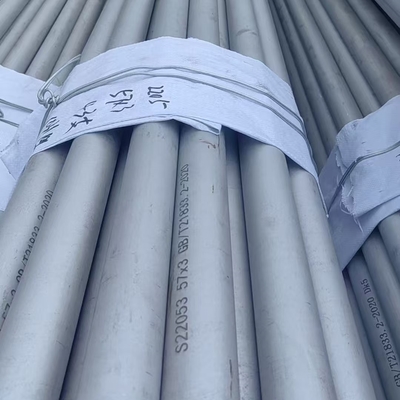

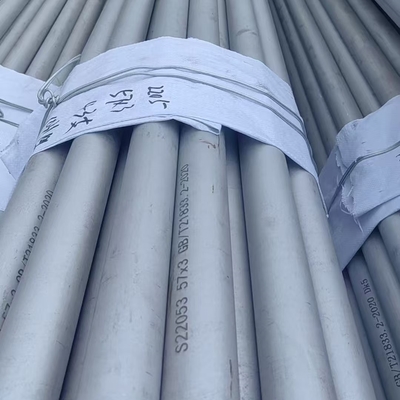

ASTM A790 Tubo de Aço Inoxidável Duplex S32550 Decapagem e Acabamento Brilhante

Detalhes do produto

| Products | Stainless Steel Seamless Pipe | Grade | S32550 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m or custom cutting any length as request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Destacar | tubulação de aço inoxidável do duplex do astm a790,Tubo de aço inoxidável S32550,Tubo de aço inoxidável decapado brilhante |

||

Descrição de produto

ASTM A790 S32550 Tubos duplex de aço inoxidável em decapagem e acabamento brilhante

Especificação dos produtos

| Nome dos produtos | Tubo duplex 2550 de aço inoxidável sem costura |

Grau: |

304 304L 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 2550 S32760 904L 254SMO e grau igual na norma GB JIS EN DIN |

| Padrões: | ASTM A213M-94b ASTM A249M-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92. | |

| O presente regulamento entra em vigor no dia seguinte ao da sua publicação no Jornal Oficial da União Europeia. | |

| GB13296-1991 GB14975-2002 GB14976-2002, ect. | |

| Tamanho: | ND5 - DN400 |

| Duração: | 6 m de comprimento ou cortando qualquer comprimento a pedido |

| Aplicações: | transporte de fluidos e gases, estrutura, caldeira, trocador de calor, superqueimador |

Os tubos e tubos duplex de aço inoxidável ASTM A790 S32550 são materiais de alto desempenho concebidos para uma extrema resistência à corrosão e integridade estrutural.também conhecido como UNS S32550 ou Ferralium 255, combina uma microestrutura equilibrada de ferrita-austenita (≈50:50) para oferecer resistência superior, durabilidade e resistência à corrosão induzida por cloreto.Abaixo está uma visão geral abrangente dos seus principais atributos:

Composição química

- Cromo (Cr): 24,027,0%

- Níquel (Ni): 4,56,5%

- Molibdênio (Mo): 2,9 ∼ 3,9%

- Cobre (Cu): 1,5 ∼2,5%

- Nitrogénio (N): 0,10 ∼0,25%

- Carbono (C): ≤ 0,04%

- Outros: Mn ≤1,5%, Si ≤1,0%, P ≤0,04%, S ≤0,03%

Propriedades mecânicas

- Resistência à tração: ≥ 750 MPa (110 ksi)

- Resistência ao rendimento (0,2% de deslocamento): ≥ 500 MPa (72,5 ksi)

- Elongação: ≥ 15%

- Dureza: 250 ‰ 330 HB

- Resistência a impactos: ≥ 60 J a -46°C

Propriedades físicas

- Densidade: 7,85 g/cm3

- Conductividade térmica: 15,1 ̊23,3 W/m·K (varia com a temperatura)

- Coeficiente de expansão térmica: 12,3 × 10−6/K (100 ≈ 500 °C)

- Resistência: 850 nΩ·m

- Ponto de fusão: 1390°C-1440°C

Desempenho

-

Resistência à corrosão

- Corrosão por fendas/fendas: temperatura crítica de fendas (CPT) ≥ 55°C (ASTM G48).

- Cracking de Corrosão por Stress (SCC): Resistência excepcional em ambientes ricos em cloreto, superando o 316L em 5×10 vezes.

- Resistência ao ácido: Resistente aos ácidos sulfúrico, fosfórico e nítrico, com baixas taxas de corrosão (por exemplo, 0,15 mm/ano em 10% FeCl3 + 3% HCl a 40 °C).

-

Força mecânica

- A alta resistência à tração (≈ 3 × a de 316L) permite projetos estruturais mais leves sem comprometer a segurança.

- Mantém a ductilidade e a dureza mesmo a temperaturas abaixo de zero (-50°C).

-

Soldabilidade

- Compatível com processos GTAW, SMAW e SAW usando metal de preenchimento ER2594.

-

Revestimento de superfície

- Picote e acabamento brilhante: remove escamas de moagem e óxidos, aumentando a resistência à corrosão e o apelo estético.

Especificações

- Dimensões:

- OD: 6 ¢ 762 mm (0,25 ¢ 30 polegadas)

- Espessura da parede: 0,5 ̊35 mm (0,02 ̊1,38 polegadas)

- Comprimento: Personalizavel (normalmente 3×12 metros)

- Métodos de fabrico:

- Sem costura: produzido por extrusão a quente ou desenho a frio.

- "Ferramentas" para a "produção" ou "produção" de "materiais" ou "materiais" de "produção" ou "produção" de "materiais" ou "materiais" de "produção" ou "produção".

- Conformidade com as normas:

- ASTM A790/A790M, ASME SA-790, EN 10216-5 e NACE MR0175.

Aplicações

-

Marítimo e Offshore:

- Sistemas de dessalinização de água do mar, oleodutos submarinos e componentes de plataformas offshore.

- Substitui o titânio nas carcasas de membrana RO, reduzindo os custos em 30%.

-

Petróleo e Gás:

- Tubos de poço, cabeças de poço e equipamentos resistentes ao H2S (até 5000 ppm de H2S).

-

Processamento químico:

- Reatores, trocadores de calor e tubulações que transportam produtos químicos agressivos (por exemplo, 60% H3PO4).

-

Mineração e Celulose/Papel:

- Tubos de transporte de lama, digestores e plantas de branqueamento devido à alta resistência à abrasão.

-

Geração de energia:

- Sistemas de dessulfuração de gases de combustão e condensadores em usinas a carvão.

Embalagens para exportação

-

Embalagem:

- Caixas/paletes de madeira: tratadas de acordo com as normas ISPM-15 (tratadas termicamente ou fumigadas) com marcações IPPC.

- Folha de plástico: Encapsula tubos para evitar a umidade e danos mecânicos.

- Cintas de aço: Fixa os feixes para estabilidade durante o transporte.

-

Proteção secundária:

- Revestimentos anti-corrosivos: Opcional, revestimentos à base de cera ou óleo para armazenagem a longo prazo.

- Marcação: especificações do produto (tipo, tamanho, lote), rótulos ISO de expedição e instruções de manuseio.

-

Documentação:

- Certificado de conformidade (CoC) com os resultados dos ensaios químicos/mecânicos.

- Relatórios de ensaio de materiais (MTR) conformes com a norma EN 10204 3.1B.

Normas e conformidade

- ASTM A790/A790M: Especificação principal para tubos de aço inoxidável duplex sem costura/soldados.

- ASME SA-790: Para aplicações que contenham pressão em caldeiras e tubulações.

- EN 1.4507: Norma europeia equivalente para o S32550.

- NACE MR0175: Conforme para ambientes de gases ácidos.

![]()

![]()

![]()

![]()

Produtos recomendados