모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

ASTM A790 S32550 듀플렉스 스테인리스강 파이프 튜브 산세 및 광택 마감

제품 상세 정보

| Products | Stainless Steel Seamless Pipe | Grade | S32550 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m or custom cutting any length as request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| 강조하다 | astm a790 듀플렉스 스테인리스강 파이프,S32550 스테인리스 스틸 튜브,비닐로 만든 밝은 스테인레스 스틸 파이프 |

||

제품 설명

ASTM A790 S32550 듀플렉스 스테인리스 스틸 파이프 파이프 피클링 및 밝은 마무리

제품 사양

| 제품 이름 | 듀플렉스 2550 스테인리스 스틸 꿰매지 않는 파이프 |

등급: |

304 304L 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 2550 S32760 904L 254SMO 및 GB JIS EN DIN 표준에서 동등한 등급 |

| 표준: | ASTM A213M-94b ASTM A249M-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92. | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994, ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect | |

| 크기: | ND5 - DN400 |

| 길이는: | 6m 길이 또는 요청에 따라 모든 길이 절단 |

| 응용 프로그램: | 유체 및 가스 운송, 구조, 보일러, 열 교환기, 슈퍼 히터 |

ASTM A790 S32550 듀플렉스 스테인리스 스틸 파이프 및 튜브는 극심한 진식 저항성과 구조적 무결성을 위해 설계 된 고성능 재료입니다. 이 합금,또한 UNS S32550 또는 Ferralium 255로 알려져 있습니다., 균형 잡힌 페리트-오스텐이트 미세 구조 (≈50:50) 를 결합하여 우수한 강도, 내구성 및 엽록소 유발 진열에 대한 저항성을 제공합니다.아래는 주요 속성의 포괄적 인 개요입니다.:

화학적 성분

- 크롬 (Cr): 24.0~27.0%

- 니켈 (Ni): 4.5~6.5%

- 몰리브덴 (Mo): 2.9~3.9%

- 구리 (Cu): 1.5~2.5%

- 질소 (N): 0.10~0.25%

- 탄소 (C): ≤0.04%

- 다른: Mn ≤1.5%, Si ≤1.0%, P ≤0.04%, S ≤0.03%

기계적 특성

- 팽창 강도: ≥750 MPa (110 ksi)

- 출력 강도 (0.2% 오프셋): ≥500 MPa (72.5 ksi)

- 연장: ≥15%

- 강도: 250~330 HB

- 충격 저항: -46°C에서 ≥60 J

물리적 특성

- 밀도: 7.85g/cm3

- 열전도: 15.1~23.3W/m·K (온도에 따라 달라집니다)

- 열 팽창 계수: 12.3×10−6/K (100~500°C)

- 저항력: 850nΩ·m

- 녹는점: 1390~1440°C

성능

-

부식 저항성

- 뚫림/크리브 코로시온: 크리틱 뚫림 온도 (CPT) ≥55°C (ASTM G48)

- 스트레스 경식 균열 (SCC): 염화질이 풍부한 환경에서 예외적인 내성, 316L보다 5~10배 더 뛰어나다.

- 산성 저항성: 황산, 인화산 및 질소산에 저항성, 낮은 부식률 (예를 들어, 40°C에서 10% FeCl3 + 3% HCl에서 0.15 mm/year)

-

기계적 강도

- 높은 팽창 강도 (≈3× 316L) 는 안전을 손상시키지 않고 가벼운 구조 디자인을 가능하게합니다.

- 유연성과 강도를 유지합니다.

-

용접 가능성

- ER2594 필러 금속을 사용하는 GTAW, SMAW 및 SAW 프로세스와 호환됩니다. 용접 후 열처리 (1020~1100 ° C 물 소화) 는 단계 균형을 최적화합니다.

-

표면 마감

- 피클링 & 밝은 마무리: 밀링 스케일 및 산소를 제거하여 부식 저항성과 미적 호소력을 향상시킵니다. 밝은 마무리 (예를 들어, 2B, BA) 는 위생적 응용에 이상적입니다.

사양

- 차원:

- OD: 6~762mm (0.25~30인치)

- 벽 두께: 0.5~35mm (0.02~1.38인치)

- 길이: 사용자 정의 가능 (일반적으로 3~12 미터)

- 제조 방법:

- 꿰매지 않는: 뜨거운 진압 또는 차가운 도면을 통해 생산됩니다.

- 용접: ERW 또는 100% NDT로 매듭없이 용접 (예: ASTM E213에 따른 초음파 검사)

- 표준 준수:

- ASTM A790/A790M, ASME SA-790, EN 10216-5 및 NACE MR0175

신청서

-

해양 및 해상:

- 해수 해소화 시스템, 수중 파이프라인, 해상 플랫폼 부품

- 티타늄을 대체하여 30%의 비용을 절감합니다.

-

석유 및 가스:

- 하구 파이프, 우물머리, H2S 저항성 장비 (H2S 최대 5000ppm)

-

화학 가공:

- 공격적인 화학물질 (예를 들어, 60% H3PO4) 을 처리하는 원자로, 열 교환기 및 파이프 라인.

-

광업 및 직물/용품:

- 고 경사 저항성 때문에 슬러리 운송 파이프, 소화기 및 블리치 플랜트.

-

전력 생산:

- 석탄 화력 발전소에서 연소 가스 탈황화 시스템 (FGD) 및 응축 튜브.

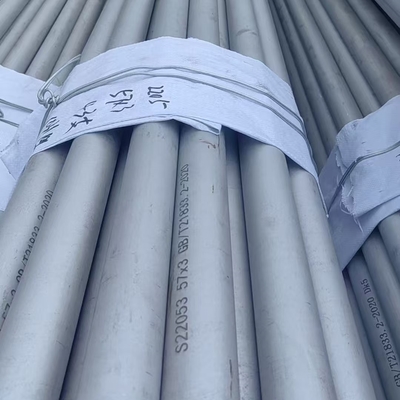

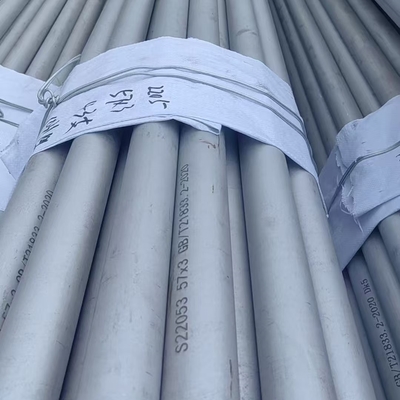

수출용 포장재

-

기본 포장:

- 목재 상자/팔렛: IPPC 표시로 ISPM-15 표준에 따라 처리 (열처리 또는 연소) 됩니다.

- 플라스틱 시트: 수분 및 기계적 손상을 방지하기 위해 파이프를 캡슐화합니다.

- 스틸 스트랩: 운송 중 안정성을 위해 뭉치를 고정합니다.

-

2차 보호:

- 부식 방지 코팅: 장기 보관을 위해 선택적으로 백스 또는 오일 기반 코팅.

- 표기: 제품 사양 (등급, 크기, 팩트), ISO 배송 라벨 및 취급 지침.

-

서류:

- 화학/기계 시험 결과를 담은 적합성 인증서 (CoC)

- EN 10204 3.1B를 준수하는 재료 시험 보고서 (MTR)

표준 및 준수

- ASTM A790/A790M: 꿰매지 않는/접속된 듀플렉스 스테인리스 스틸 파이프의 주요 사양.

- ASME SA-790: 보일러 및 파이프 라인에서의 압력 함유 용도.

- EN 14507: S32550에 대한 유럽 동등 표준.

- NACE MR0175: 산성 가스 환경에 적합합니다.

![]()

![]()

![]()

![]()

추천된 제품