-

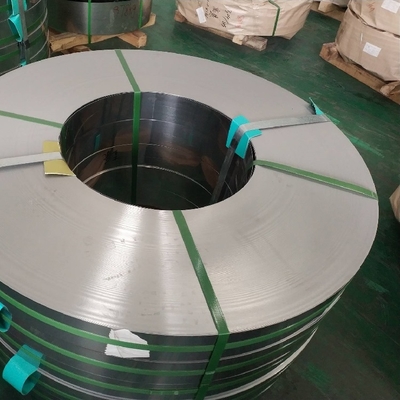

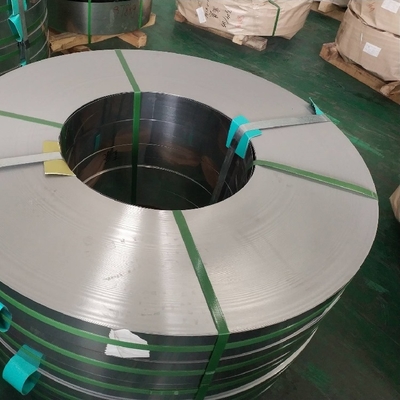

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Bandes de précision Hastelloy C276 Épaisseur 0,1 à 2,5 mm Largeur 10 à 600 mm

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | DELTA |

| Certification | ISO |

| Numéro de modèle | UNS N10276 |

| Quantité de commande min | 500 kg |

| Prix | 40-45 USD/Kg |

| Détails d'emballage | Emballage standard pour l'exportation |

| Délai de livraison | 5 - 12 jours en fonction de la quantité |

| Conditions de paiement | L / C, T / T, Western Union |

| Capacité d'approvisionnement | 3 tonnes par semaine |

Contactez-moi pour des aperçus gratuits et des bons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Produits | Bandes Hastelloy C276 | Grade | UNS N10276 |

|---|---|---|---|

| Épaisseur | 0,1 - 2,5 mm | Largeur | 1000 mm 1219 mm 1500 mm |

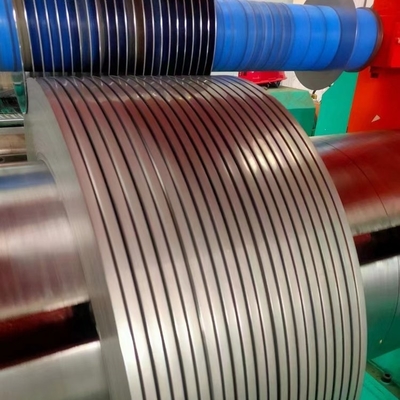

| Standard | Astm en | SERVICE | bandes de coupe personnalisées dans n'importe quelle largeur et épaisseur |

| Port de chargement | Port de Shanghai | Surface | 2B NO.1 |

| Mettre en évidence | Bandes de précision en Hastelloy C276,Bandes en alliage de nickel résistant à la corrosion,Bandes métalliques minces en Hastelloy C276 |

||

Bandes de précision Hastelloy C276 Épaisseur 0,1 à 2,5 mm Largeur 10 à 600 mm

Renseignements rapides

| Grade | Hastelloy C276 / 2 est un produit chimique.4819 | Le type | des bandes |

| Épaisseur | 0.1 à 2,5 mm | Largeur | 5 - 1219 mm sur demande |

| Surface | 2B | Diamètre intérieur | 508 mm ou sur demande |

Plus d'informations sur les spécifications

| Nom du produit | bandes de Hastelloy C276 en alliage de nickel |

| Épaisseur | 0.1 à 2,5 mm |

| Largeur | 5 - 1219 mm |

| Surface | 2B |

| Marque | Délta |

| Le service | Traitement des petites bobines |

| Nombre de pièces | 2 kilos |

| Autre type | Barre ronde, feuille, plaque, bobine, tuyau, etc. |

| Emballage | papier étanche et palettes en bois, boîte en bois |

| Port de chargement | Port de Shanghai |

| Période de prix | Ex-W, FOB, CIF, CFR |

| Temps de livraison | dans les 12 jours |

Bandes de précision Hastelloy C276 Épaisseur 0,1 à 2,5 mm Largeur 10 à 600 mm

1Composition chimique

- Nickel (Ni): 54,0% - 60,0% (élément matrice, fournissant une résistance de base et une résistance à la corrosion)

- Chrome (Cr): 14,5% - 16,5% (améliore la résistance aux milieux oxydants tels que l'acide nitrique et l'oxydation à haute température)

- Molybdène (Mo): 15,0% - 17,0% (améliore la résistance aux milieux non oxydants tels que l' acide chlorhydrique et l' acide sulfurique, et améliore la résistance aux fosses)

- Tungstène (W): 3,0% - 4,5% (synergie avec le molybdène pour améliorer encore la résistance à la corrosion et la résistance mécanique)

- Fer (Fe): 4,0% - 7,0% (optimise la traçabilité de l'alliage et réduit le coût des matériaux sans compromettre les propriétés clés)

- Carbon (C): ≤ 0,01% (réduit au minimum pour éviter la formation de précipitations de carbure, ce qui pourrait provoquer une corrosion intergranulaire)

- Silicium (Si): ≤ 0,08%

- Manganèse (Mn): ≤ 1,0%

- Phosphore (P): ≤ 0,04%

- Soufre (S): ≤ 0,03%

2Propriétés mécaniques

- Résistance à la traction (σb): ≥ 690 MPa (la contrainte maximale que la bande peut supporter avant de se casser, ce qui garantit sa résistance aux forces de traction en service)

- Résistance au rendement (σ0,2): ≥ 310 MPa (la contrainte à laquelle la bande commence à subir une déformation permanente, empêchant une déformation excessive sous charges de travail)

- L'allongement (δ): ≥ 40% (pourcentage de déformation plastique avant fracture, indiquant une bonne ductilité pour des procédés tels que la flexion et le formage)

- Dureté (HB): ≤ 210 (Dureté de Brinell, reflétant la résistance du matériau à l'indentation; une dureté inférieure à l'état recuit facilite l'usinage et le formage)

3. Spécifications et normes

3.1 Spécifications dimensionnelles

- Épaisseur: 0,1 mm - 2,5 mm (les épaisseurs courantes comprennent 0,1 mm, 0,2 mm, 0,5 mm, 1,0 mm, 1,5 mm, 2,0 mm, 2,5 mm; la tolérance à l'épaisseur peut être réglée entre ±0,01 mm et ±0,05 mm selon l'épaisseur,pour assurer une haute précision dimensionnelle pour les ensembles serrés)

- Largeur: 10 mm - 600 mm (des largeurs personnalisées dans cette plage sont disponibles; la tolérance de largeur est généralement de ± 0,1 mm - ± 0,3 mm, adaptée à la fois aux composants de petite taille et aux applications de revêtement de grande surface)

- Longueur: les longueurs standard sont de 2000 mm, 3000 mm ou 5000 mm; des formes de bobines (avec un diamètre intérieur de 508 mm ou 610 mm) sont également proposées pour les lignes de production continues,réduction des déchets de matériaux et amélioration de l'efficacité.

3.2 Normes exécutives

- ASTM B575 (États-Unis): spécification standard pour la plaque, la feuille et la bande en alliage de nickel, couvrant la composition du matériau, les propriétés mécaniques et les tolérances dimensionnelles.

- ASME SB575 (États-Unis): la version du code des récipients sous pression de l'ASTM B575, obligatoire pour les bandes utilisées dans les récipients sous pression et les chaudières.

- DIN EN 10095 (Europe): Norme européenne pour le nickel et le nickel - plaque, feuille et bande en alliage, largement reconnue sur le marché européen.

- GB/T 2054 (Chine): Norme nationale pour le nickel et la plaque, la feuille et la bande en alliage de nickel, applicable aux applications domestiques en Chine.

4. Grades équivalents

- États-Unis: UNS N10276 (désigné par le système unifié de numérotation des métaux et alliages)

- Europe: W. Nr. 2.4819 (numéro allemand Werkstoff, utilisé dans les normes DIN/EN)

- Chine: NS3304 (notation de la norme nationale selon GB/T 15007)

- Japon: NCF276 (classe standard du SIG)

5. Applications

- Industrie de transformation chimique: Utilisé pour la fabrication de composants tels que des joints, des diaphragmes, des plaques d'échangeurs de chaleur et des sièges de vannes dans des équipements destinés à produire ou à traiter des produits chimiques agressifs (par exemple,acide sulfuriqueIl résiste à la corrosion des acides oxydants et non oxydants.

- Industrie pétrolière et gazière: Appliquée dans les composants tubulaires pour puits, les bandes d'équipement de tête de puits et les revêtements de pipelines pour le forage pétrolier offshore et l'extraction de gaz acide (contenant du H2S).Il résiste efficacement à la fissuration par corrosion par stress de sulfure (SSC) et à la crevaison à haute température., environnements de champs pétrolifères à haute pression.

- Industrie de la protection de l'environnement: utilisé pour fabriquer des membranes filtrantes, des composants du système de désulfuration des gaz de combustion (FGD) et des pièces d'équipement de traitement des eaux usées.Il peut résister à la corrosion des gaz de combustion acides (contenant du SO2) et des eaux usées corrosives, assurant une longue durée de vie des équipements de protection de l'environnement.

- Industrie pharmaceutique et alimentaire: utilisée dans la production de composants de précision pour réacteurs pharmaceutiques, équipements de transformation alimentaire (par exemple, machines à conserver) et systèmes de traitement de l'eau pure.Sa faible teneur en carbone et son excellente résistance à la corrosion empêchent la lixiviation des ions métalliques, répondant ainsi aux exigences strictes d'hygiène de ces industries.

- Industrie aérospatiale et électronique: Utilisé pour fabriquer des composants structurels légers, des capteurs à haute température et des connecteurs de précision dans les moteurs aérospatiaux.Il sert également de matériau de base de revêtement résistant à la corrosion pour les composants électroniques, assurant des performances stables dans des environnements extrêmes (par exemple, haute température, humidité élevée).

![]()

![]()

![]()

![]()