All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

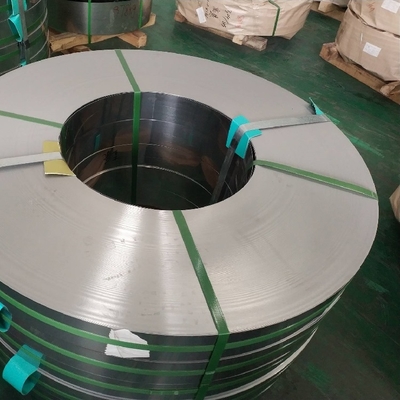

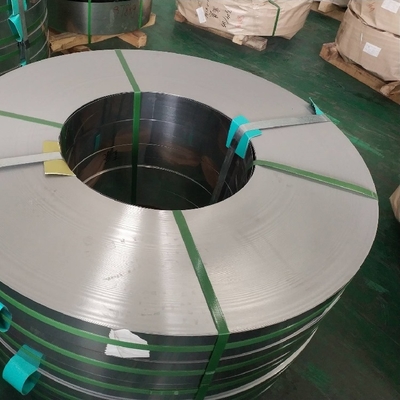

Precision Strips Hastelloy C276 Thickness 0.1 - 2.5mm Width 10 - 600mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Hastelloy C276 Strips | Grade | UNS N10276 |

|---|---|---|---|

| Thickness | 0.1 - 2.5mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Custom Cutting Strips In Any Width And Thickness |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | Hastelloy C276 precision strips,Nickel alloy corrosion-resistant strips,Hastelloy C276 thin metal strips |

||

Product Description

Precision Strips Hastelloy C276 Thickness 0.1 - 2.5mm Width 10 - 600mm

Quick Informations

| Grade | Hastelloy C276 / 2.4819 | Type | strips |

| Thickness | 0.1 - 2.5mm | Width | 5 - 1219mm as request |

| Surface | 2B | Innder Diameter | 508mm or as request |

More Specification Informations

| Products Name | Hastelloy C276 Nickel Alloy strips |

| Thickness | 0.1 - 2.5mm |

| Width | 5 - 1219mm |

| Surface | 2B |

| Brand | DELTA |

| Service | Small coil processing |

| MOQ | 2 Kgs |

| Other Type | round bar, sheet,plate,coil,pipe.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Precision Strips Hastelloy C276 Thickness 0.1 - 2.5mm Width 10 - 600mm

Hastelloy C276 precision strips, with a thickness range of 0.1 - 2.5mm and a width range of 10 - 600mm, are high-performance nickel - chromium - molybdenum alloy strips renowned for their exceptional corrosion resistance, excellent mechanical properties, and stable dimensional accuracy. They are widely used in harsh industrial environments where resistance to aggressive media is critical, making them a preferred material in sectors such as chemical processing, oil and gas, and environmental protection.

1. Chemical Composition

Hastelloy C276 is a nickel - based superalloy with a carefully formulated chemical composition that endows it with outstanding corrosion resistance, especially against pitting, crevice corrosion, and stress corrosion cracking. The typical chemical composition (by weight percentage) is as follows:

- Nickel (Ni): 54.0% - 60.0% (matrix element, providing base strength and corrosion resistance)

- Chromium (Cr): 14.5% - 16.5% (enhances resistance to oxidizing media such as nitric acid and high - temperature oxidation)

- Molybdenum (Mo): 15.0% - 17.0% (improves resistance to non - oxidizing media like hydrochloric acid and sulfuric acid, and enhances pitting resistance)

- Tungsten (W): 3.0% - 4.5% (synergizes with molybdenum to further boost corrosion resistance and mechanical strength)

- Iron (Fe): 4.0% - 7.0% (optimizes alloy processability and reduces material cost without compromising key properties)

- Carbon (C): ≤ 0.01% (minimized to prevent the formation of carbide precipitates, which could cause intergranular corrosion)

- Silicon (Si): ≤ 0.08%

- Manganese (Mn): ≤ 1.0%

- Phosphorus (P): ≤ 0.04%

- Sulfur (S): ≤ 0.03%

2. Mechanical Properties

The mechanical properties of Hastelloy C276 precision strips (in the annealed state, which is the most common state for precision strips) are stable and reliable, ensuring they can withstand various mechanical stresses in practical applications. The key mechanical performance indicators are:

- Tensile Strength (σb): ≥ 690 MPa (the maximum stress the strip can withstand before breaking, ensuring it resists pulling forces in service)

- Yield Strength (σ0.2): ≥ 310 MPa (the stress at which the strip begins to undergo permanent deformation, preventing excessive deformation under working loads)

- Elongation (δ): ≥ 40% (the percentage of plastic deformation before fracture, indicating good ductility for processes like bending and forming)

- Hardness (HB): ≤ 210 (Brinell hardness, reflecting the material's resistance to indentation; a lower hardness in the annealed state facilitates machining and forming)

Note: For strips that require higher strength (e.g., for structural components in high - pressure environments), cold - worked states (such as 1/4 hard, 1/2 hard, or full hard) can be provided. In cold - worked states, tensile strength and hardness increase significantly, while elongation decreases. Specific properties can be customized according to customer requirements.

3. Specifications and Standards

3.1 Dimensional Specifications

The core dimensional range of the Hastelloy C276 precision strips covered in this introduction is tailored to meet the diverse needs of precision manufacturing:

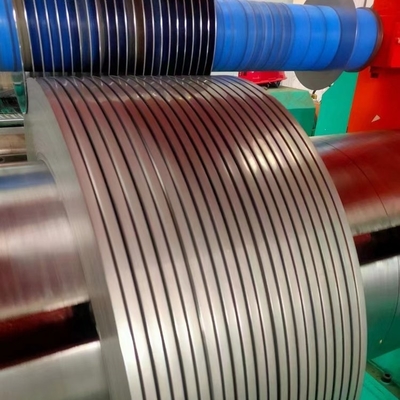

- Thickness: 0.1mm - 2.5mm (common thicknesses include 0.1mm, 0.2mm, 0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm; thickness tolerance can be controlled within ±0.01mm - ±0.05mm depending on the thickness, ensuring high dimensional precision for tight - fit assemblies)

- Width: 10mm - 600mm (custom widths within this range are available; width tolerance is typically ±0.1mm - ±0.3mm, suitable for both small - size components and large - area cladding applications)

- Length: Standard lengths are 2000mm, 3000mm, or 5000mm; coil forms (with inner diameter 508mm or 610mm) are also offered for continuous production lines, reducing material waste and improving efficiency.

3.2 Executive Standards

Hastelloy C276 precision strips are produced in strict accordance with international and industry standards to ensure consistent quality and interchangeability. The main applicable standards are:

- ASTM B575 (USA): Standard specification for nickel - alloy plate, sheet, and strip, covering material composition, mechanical properties, and dimensional tolerances.

- ASME SB575 (USA): The pressure vessel code version of ASTM B575, mandatory for strips used in pressure vessels and boilers.

- DIN EN 10095 (Europe): European standard for nickel and nickel - alloy plate, sheet, and strip, widely recognized in the European market.

- GB/T 2054 (China): National standard for nickel and nickel - alloy plate, sheet, and strip, applicable to domestic applications in China.

4. Equivalent Grades

Hastelloy C276 is an internationally recognized alloy grade, and different countries and regions have established equivalent grades to facilitate material selection and trade. The main equivalent grades are:

- USA: UNS N10276 (designated by the Unified Numbering System for Metals and Alloys)

- Europe: W. Nr. 2.4819 (German Werkstoff number, used in DIN/EN standards)

- China: NS3304 (national standard grade in GB/T 15007)

- Japan: NCF276 (JIS standard grade)

These equivalent grades have nearly identical chemical compositions and mechanical properties to Hastelloy C276, ensuring that they can be used interchangeably in most applications (minor differences in impurity content may exist, so it is recommended to confirm with standards before use).

5. Applications

Owing to its excellent corrosion resistance, stable mechanical properties, and precise dimensions, Hastelloy C276 precision strips are widely used in industries that operate in harsh environments. The typical application fields are:

- Chemical Processing Industry: Used to manufacture components such as gaskets, diaphragms, heat exchanger plates, and valve seats in equipment for producing or processing aggressive chemicals (e.g., sulfuric acid, hydrochloric acid, acetic acid, and organic halides). It resists corrosion from both oxidizing and non - oxidizing acids.

- Oil and Gas Industry: Applied in downhole tubular components, wellhead equipment strips, and pipeline liners for offshore oil drilling and sour gas (containing H₂S) extraction. It effectively resists sulfide stress corrosion cracking (SSC) and pitting in high - temperature, high - pressure oilfield environments.

- Environmental Protection Industry: Used to make filter membranes, flue gas desulfurization (FGD) system components, and wastewater treatment equipment parts. It can withstand corrosion from acidic flue gas (containing SO₂) and corrosive wastewater, ensuring long - term service life of environmental protection equipment.

- Pharmaceutical and Food Industry: Utilized in the production of precision components for pharmaceutical reactors, food processing equipment (e.g., canning machinery), and pure water treatment systems. Its low carbon content and excellent corrosion resistance prevent metal ion leaching, meeting the strict hygiene requirements of these industries.

- Aerospace and Electronics Industry: Used to manufacture lightweight structural components, high - temperature sensor shells, and precision connectors in aerospace engines. It also serves as a corrosion - resistant coating base material for electronic components, ensuring stable performance in extreme environments (e.g., high temperature, high humidity).

![]()

![]()

![]()

![]()

Recommended Products