Todos los productos

-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Barra brillante pulida Hastelloy C276 estándar ASTM EN GB JIS Barras redondas forjadas y laminadas en caliente

| Lugar de origen | PORCELANA |

|---|---|

| Nombre de la marca | DELTA |

| Certificación | ISO |

| Número de modelo | Hastelloy C276 |

| Cantidad de orden mínima | 10 kg |

| Precio | 40 - 50 USD/Kg |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días basado en la cantidad |

| Condiciones de pago | L/C, T/T, Western Union |

| Capacidad de la fuente | 3 toneladas por semana |

Datos del producto

| Productos | Barra brillante de Hastelloy C276 | Calificación | Hastelloy C276 |

|---|---|---|---|

| Diámetro | 5 - 350 mm | Longitud | corte personalizado de cualquier longitud a petición |

| Estándar | ASTM EN | Servicio | CORTE |

| Puerto de carga | Puerto de Shanghai | Superficie | Brillante |

| Resaltar | Hastelloy c276 alrededor de la barra,Barra de aleación de níquel estándar ASTM,Barra Hastelloy pulida brillante |

||

Descripción de producto

Barras redondas pulidas brillantes Hastelloy C276 estándar ASTM EN GB JIS Barras redondas forjadas y laminadas en caliente

Más información sobre especificaciones

| Nombre del producto | Barra brillante Hastelloy C276 |

| Diámetro | 5 - 350 mm |

| Longitud | corte personalizado de cualquier longitud según solicitud |

| Superficie | brillante, negro |

| Marca | DELTA |

| Servicio | corte, pulido |

| MOQ | 2 Kgs |

| Otro tipo | barra, tira, bobina, tubo, lámina, placa, alambre, etc. |

| Embalaje | Caja de madera |

| Puerto de carga | Puerto de Shanghái |

| Término de precio | EXW, FOB, CIF, CFR |

| Tiempo de entrega | dentro de 12 días |

Barras redondas pulidas brillantes Hastelloy C276 estándar ASTM EN GB JIS Barras redondas forjadas y laminadas en caliente

Las barras redondas pulidas brillantes Hastelloy C276 son un pináculo de las aleaciones de níquel-cromo-molibdeno de alto rendimiento, diseñadas para sobresalir en los entornos industriales más exigentes. Combinando una resistencia a la corrosión excepcional, una resistencia mecánica robusta y una precisión dimensional constante, estas barras forjadas y laminadas en caliente cumplen con los estándares globales, incluidos ASTM, EN, GB y JIS, lo que las convierte en una opción preferida en sectores críticos de todo el mundo.

Propiedades principales y ventajas de rendimiento

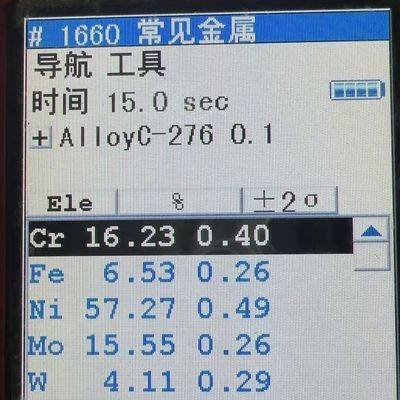

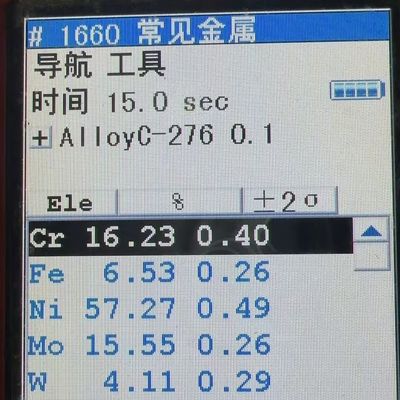

En el corazón de la superioridad de Hastelloy C276 se encuentra su composición química meticulosamente equilibrada. Dominada por el níquel (contenido de equilibrio), integra 14,5-16,5% de cromo, 15,0-17,0% de molibdeno, 3,0-4,5% de tungsteno y 4,0-7,0% de hierro, con límites estrictos de carbono (0,02% máx.) y cobalto (2,5% máx.). Esta formulación ofrece una resistencia incomparable a la corrosión por picaduras, la corrosión por hendiduras y el agrietamiento por corrosión bajo tensión tanto en medios oxidantes como reductores, desde el ácido sulfúrico en plantas químicas hasta entornos marinos ricos en cloruro.

La estabilidad a altas temperaturas distingue aún más estas barras, que mantienen la integridad estructural hasta 1040 °C. Con una densidad de 8,89 g/cm³ y un módulo de elasticidad de 205 GPa, ofrecen una rara combinación de ductilidad y resistencia: las barras recocidas alcanzan una resistencia a la fluencia de 455 MPa y una resistencia a la tracción de 842 MPa con una elongación del 40%, mientras que las variantes trabajadas en frío alcanzan hasta 1724 MPa de resistencia a la fluencia. El acabado pulido brillante mejora estas propiedades al eliminar las imperfecciones de la superficie que podrían iniciar la corrosión, lo que garantiza un rendimiento a largo plazo en condiciones adversas.

Cumplimiento de los estándares globales

El cumplimiento de los estándares internacionales garantiza la coherencia y la interoperabilidad en todos los proyectos. La siguiente tabla describe las especificaciones clave:

| Sistema estándar | Grado relevante | Especificación clave | Tolerancia dimensional |

|---|---|---|---|

| ASTM/ASME | UNS N10276 | ASTM B574 | H8-H13, K9-K12 |

| EN/DIN | 2.4819 | EN 10088-3 | H8-H13, K9-K12 |

| GB | N06276 | GB/T 15007 | H8-H13, K9-K12 |

| JIS | NW276 | JIS G4902 | H8-H13, K9-K12 |

Todas las barras se someten a pruebas rigurosas, incluido el análisis de la composición química, la verificación de las propiedades mecánicas y la inspección del acabado de la superficie, con certificados como ISO, SGS y EN 10204-3.1 disponibles bajo petición.

Especificaciones del producto

Dimensiones y formas

Las barras redondas pulidas brillantes Hastelloy C276 se adaptan a diversas necesidades industriales con un tamaño flexible:

- Rango de diámetro: 3,17 mm a 350 mm (laminado en caliente: 10-250 mm; estirado en frío: 4-60 mm)

- Longitud: 100 mm a 6000 mm, con corte personalizado disponible

- Acabado: Pulido brillante (Ra ≤ 0,8 μm), con opciones de acabado BA o acabado No.4

- Procesamiento: Laminado en caliente para diámetros mayores, forjado para una estructura de grano mejorada y estirado en frío para tolerancias ajustadas

Propiedades mecánicas (Valores típicos)

| Condición | Resistencia a la fluencia (MPa) | Resistencia a la tracción (MPa) | Elongación (%) |

|---|---|---|---|

| Recocido | 455 | 842 | 40 |

| 40% Trabajado en frío | 1310 | 1531 | 3.8 |

| 75% Trabajado en frío | 1724 | 1999 | 3.9 |

*Datos basados en una longitud de calibre de prueba de 25,4 cm a 22 °C; los resultados pueden variar según el diámetro*

Aplicaciones industriales

La versatilidad de las barras pulidas brillantes Hastelloy C276 las hace indispensables en industrias de alto riesgo:

- Petroquímica y petróleo/gas: Se utiliza para válvulas, ejes de bombas e internos de reactores, resistiendo el gas agrio y la corrosión por cloruro.

- Procesamiento químico: Ideal para agitadores y componentes de intercambiadores de calor en entornos con ácidos sulfúrico, clorhídrico y acético.

- Productos farmacéuticos y procesamiento de alimentos: Cumple con los estándares de higiene para equipos que requieren resistencia a la corrosión y fácil limpieza.

- Aeroespacial y energía: Fabricado en piezas de turbinas y componentes de reactores nucleares, soportando temperaturas y presiones extremas.

Garantía de calidad y embalaje

Cada barra presenta una marca permanente con el grado del material, el código de calor, el símbolo del fabricante y la designación estándar para la trazabilidad. El embalaje incluye papel impermeable y envoltura de lámina de plástico para evitar la contaminación durante el transporte, con embalaje personalizado disponible para pedidos grandes. La cantidad mínima de pedido comienza en 10 kg, con una capacidad de suministro de 500 toneladas mensuales para satisfacer los requisitos de lotes pequeños y a granel.

Respaldadas por el cumplimiento de los estándares globales y el rendimiento comprobado en entornos hostiles, las barras redondas pulidas brillantes Hastelloy C276 ofrecen confiabilidad donde la falla del material no es una opción. Ya sea para equipos de procesamiento químico o componentes aeroespaciales, estas barras combinan la ingeniería de precisión con una durabilidad excepcional.

![]()

![]()

![]()

![]()

Productos recomendados