すべての製品

-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

ASTM EN GB JIS規格 ハステロイC276 光沢研磨棒 熱間圧延および鍛造丸棒

商品の詳細

| 製品 | ハステロイC276 明るいバー | 学年 | Hastelloy C276 |

|---|---|---|---|

| 直径 | 5~350mm | 長さ | 要求に応じて任意の長さで切断 |

| 標準 | ASTM EN | サービス | 切断 |

| ロードポート | 上海港 | 表面 | 明るい |

| ハイライト | 丸棒Hastelloy c276,ASTM規格ニッケル合金バー,光沢研磨ハステロイバー |

||

製品の説明

ASTM EN GB JIS 標準 ハステロイ C276 明るく磨いた棒 ホットロールおよび鍛造された丸い棒

詳細情報

| 商品名 | ハステロイC276 ブライトバー |

| 直径 | 5 - 350mm |

| 長さ | 要求に応じて任意の長さのカスタムカット |

| 表面 | 明るい黒 |

| ブランド | デルタ |

| サービス | 切る,磨く |

| MOQ | 2kg |

| 他のタイプ | 棒,ストライプ,コイル,パイプ,シート,プレート,ワイヤ,など |

| 梱包 | 木製の箱 |

| ロードポート | 上海港 |

| 価格期間 | EXW FOB CIF CFR |

| 配達時間 | 12日以内に |

ASTM EN GB JIS 標準 ハステロイ C276 明るく磨いた棒 ホットロールおよび鍛造された丸い棒

ハステロイC276 明るく磨かれた丸い棒は 高性能ニッケル-クロム-モリブデン合金の一番の頂点です 最も厳しい産業環境で優れているように設計されています特殊な耐腐蝕性を組み合わせる堅牢な機械的強度と一貫した寸法精度,これらの熱巻きと鍛造棒は,ASTM,EN,GB,JISを含む国際基準を満たします.世界中で重要な分野において 優先される選択肢になります.

主要な特性と性能上の利点

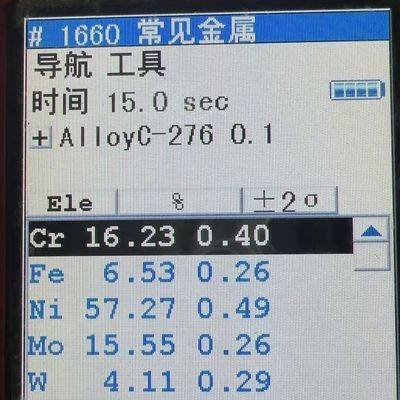

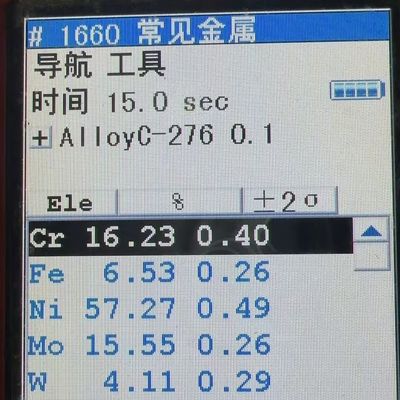

ハステロイC276の優位性の核心は,細心のバランスのとれた化学組成にあります.ニッケル (バランス含有量) が優勢です.それは14.5-16.5%のクロム,15.0-17.0%のモリブデン,3.0から4. 5% ワルフスタンと4.0~7.0% 鉄,炭素の厳格な制限 (0.02% 最大) とコバルト (2.5% 最大).この配合は,穴,亀裂腐食,化学工場の硫酸から塩化物豊富な海洋環境まで.

高温安定性により,これらの棒は1040°Cまで構造的整合性を保ち,密度8.89g/cm3と弾性積205GPaで,柔らかさと強さの 希少な組み合わせです熱製棒は455MPaの強度と842MPaの拉伸強度で40%の長さで,冷加工型は1724MPaの強度に達する.明るく 磨き上げ られ た 仕上げ は,腐食 を 引き起こす 表面 の 欠陥 を 排除 し て,これら の 特性 を 強化 し ます厳しい条件下で長期的に性能を保証します

グローバル 標準 に 準拠 する

国際規格の遵守は,プロジェクト間の一貫性と相互運用性を保証します.下記の表は,主要な仕様を概要しています:

| 標準システム | 関連グレード | 主要な仕様 | 次元容量 |

|---|---|---|---|

| ASTM/ASME | UNS N10276 | ASTMB574 | H8-H13,K9-K12 |

| EN/DIN | 2.4819 | EN 10088-3 | H8-H13,K9-K12 |

| GB | N06276 について | GB/T 15007 | H8-H13,K9-K12 |

| JIS | NW276 | JIS G4902 | H8-H13,K9-K12 |

すべての棒は,化学組成分析,機械性能検証,表面仕上げ検査を含む厳格な試験を受け,ISO,SGS,EN 10204-3などの証明書があります.1 要求に応じられる.

製品仕様

寸法 と 形状

ハステロイC276 鮮明に磨かれた丸い棒は,柔軟なサイズで様々な産業用ニーズに対応します:

- 直径範囲: 3.17 mm から 350 mm (熱巻き: 10-250 mm;冷引: 4-60 mm)

- 長さ: 100mmから6000mm,カスタム切断が可能

- 仕上げ: 明るく磨かれた (Ra ≤ 0.8 μm),BA仕上げまたはNo.4仕上げのオプション

- 加工:直径を大きくするために熱巻き,穀物構造を強化するために鍛造,厳格な許容度のために冷たい引き込み

メカニカルプロパティ (典型的な値)

| 条件 | 性能強度 (MPa) | 張力強度 (MPa) | 伸縮 (%) |

|---|---|---|---|

| アニール | 455 | 842 | 40 |

| 40% 冷凍加工 | 1310 | 1531 | 3.8 |

| 75% 冷凍加工 | 1724 | 1999 | 3.9 |

*22°Cの試験計長25.4cmに基づくデータ;直径によって結果が異なる場合がある*

産業用用途

ハステロイC276 鮮明に磨き上げられた棒の多用性により 高リスク産業では不可欠です

- 石油化学および石油/ガス: バルブ,ポンプシャフト,および原子炉内部に使用され,酸性ガスおよび塩化物腐食に抵抗する.

- 化学加工:硫酸,塩化水素,乙酸を含む環境における調動器と熱交換器の部品に最適です.

- 医薬品・食品加工: 耐腐食性があり 簡単に清掃できる設備の衛生基準を満たす

- 航空宇宙・エネルギー: タービン部品と原子炉部品に製造され,極端な温度と圧力に耐える.

品質保証と包装

各棒には,材料のグレード,熱コード,製造者のシンボル,および追跡可能な標準的な指定の恒久的なマークがあります.輸送中に汚染を防ぐために,水に耐える紙とプラスチック製の紙包装を含むパッケージ大量注文ではカスタムキャテリングが可能です.最小注文量は10kgから始まり,少量および散装の需要の両方をサポートするために毎月500トンの供給能力があります.

国際基準の遵守と厳しい環境での性能を証明した ハステロイC276 明るく磨かれた丸い棒は 材料の故障が選択肢でない場合に信頼性を提供します化学加工機器や航空宇宙部品用精密な工学と 優れた耐久性を兼ね備えています

![]()

![]()

![]()

![]()

推薦されたプロダクト