모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

ASTM EN GB JIS 표준 하스텔로이 C276 밝게 닦은 바 핫 롤링 및 조형 둥근 바

제품 상세 정보

| 제품 | Hastelloy C276 밝은 봉 | 등급 | Hastelloy C276 |

|---|---|---|---|

| 지름 | 5 - 350mm | 길이 | 요청에 따라 모든 길이를 커스터마 절단합니다 |

| 기준 | astm en | 서비스 | 절단 |

| 로딩 포트 | 상하이 항구 | 표면 | 밝은 |

| 강조하다 | 하스텔로이 c276 둥근 봉,ASTM 표준 니켈 합금 바,밝게 연마된 Hastelloy 바 |

||

제품 설명

ASTM EN GB JIS 표준 Hastelloy C276 밝게 연마된 바, 열간 압연 및 단조 원형 바

추가 사양 정보

| 제품 이름 | Hastelloy C276 밝은 바 |

| 직경 | 5 - 350mm |

| 길이 | 요청에 따라 맞춤 절단 |

| 표면 | 밝음, 검정 |

| 브랜드 | DELTA |

| 서비스 | 절단, 연마 |

| MOQ | 2 Kgs |

| 기타 유형 | 바, 스트립, 코일, 파이프, 시트, 플레이트, 와이어 등 |

| 포장 | 나무 상자 |

| 선적 항구 | 상하이 항구 |

| 가격 조건 | EXW, FOB, CIF, CFR |

| 배송 시간 | 12일 이내 |

ASTM EN GB JIS 표준 Hastelloy C276 밝게 연마된 바, 열간 압연 및 단조 원형 바

Hastelloy C276 밝게 연마된 원형 바는 가장 까다로운 산업 환경에서 탁월하도록 설계된 고성능 니켈-크롬-몰리브덴 합금의 정점입니다. 뛰어난 내식성, 강력한 기계적 강도, 일관된 치수 정밀도를 결합하여 ASTM, EN, GB 및 JIS를 포함한 글로벌 표준을 충족하므로 전 세계 주요 분야에서 선호되는 선택입니다.

핵심 특성 및 성능 장점

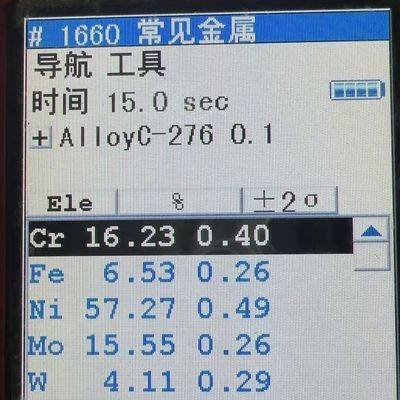

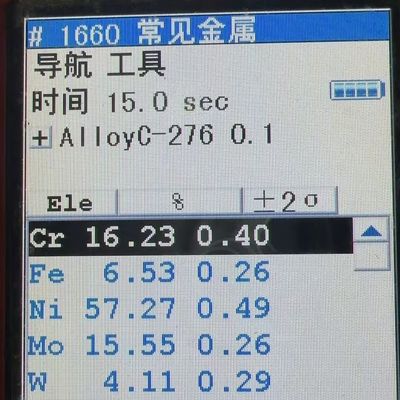

Hastelloy C276의 우수성의 핵심은 세심하게 균형 잡힌 화학적 조성에 있습니다. 니켈(균형 함량)이 지배적이며 14.5-16.5% 크롬, 15.0-17.0% 몰리브덴, 3.0-4.5% 텅스텐 및 4.0-7.0% 철을 통합하고 탄소(최대 0.02%) 및 코발트(최대 2.5%)에 대한 엄격한 제한을 둡니다. 이 제형은 화학 공장의 황산에서 염화물 함유 해양 환경에 이르기까지 산화성 및 환원성 매체 모두에서 피팅, 틈새 부식 및 응력 부식 균열에 대한 탁월한 저항성을 제공합니다.

고온 안정성은 최대 1040°C까지 구조적 무결성을 유지하는 이러한 바를 더욱 돋보이게 합니다. 밀도가 8.89 g/cm³이고 탄성 계수가 205 GPa인 이 제품은 연성 및 강도의 드문 조합을 제공합니다. 어닐링된 바는 455 MPa 항복 강도와 842 MPa 인장 강도, 40% 신장을 달성하는 반면, 냉간 가공 변형은 최대 1724 MPa 항복 강도에 도달합니다. 밝게 연마된 마감은 부식을 시작할 수 있는 표면 결함을 제거하여 이러한 특성을 향상시켜 가혹한 조건에서 장기적인 성능을 보장합니다.

글로벌 표준 준수

국제 표준 준수는 프로젝트 전반에 걸쳐 일관성과 상호 운용성을 보장합니다. 아래 표는 주요 사양을 간략하게 보여줍니다.

| 표준 시스템 | 관련 등급 | 주요 사양 | 치수 공차 |

|---|---|---|---|

| ASTM/ASME | UNS N10276 | ASTM B574 | H8-H13, K9-K12 |

| EN/DIN | 2.4819 | EN 10088-3 | H8-H13, K9-K12 |

| GB | N06276 | GB/T 15007 | H8-H13, K9-K12 |

| JIS | NW276 | JIS G4902 | H8-H13, K9-K12 |

모든 바는 화학적 조성 분석, 기계적 특성 검증 및 표면 마감 검사를 포함한 엄격한 테스트를 거치며, ISO, SGS 및 EN 10204-3.1과 같은 인증서는 요청 시 제공됩니다.

제품 사양

치수 및 형태

Hastelloy C276 밝게 연마된 원형 바는 다양한 산업 요구 사항을 유연하게 수용합니다.

- 직경 범위: 3.17mm ~ 350mm(열간 압연: 10-250mm; 냉간 인발: 4-60mm)

- 길이: 100mm ~ 6000mm, 맞춤 절단 가능

- 마감: 밝게 연마됨(Ra ≤ 0.8 μm), BA 마감 또는 No.4 마감 옵션 포함

- 가공: 더 큰 직경의 경우 열간 압연, 향상된 결정 구조를 위해 단조, 엄격한 공차를 위해 냉간 인발

기계적 특성(일반 값)

| 상태 | 항복 강도(MPa) | 인장 강도(MPa) | 신장(%) |

|---|---|---|---|

| 어닐링 | 455 | 842 | 40 |

| 40% 냉간 가공 | 1310 | 1531 | 3.8 |

| 75% 냉간 가공 | 1724 | 1999 | 3.9 |

*22°C에서 25.4cm 테스트 게이지 길이를 기준으로 한 데이터; 결과는 직경에 따라 다를 수 있습니다*

산업 응용 분야

Hastelloy C276 밝게 연마된 바의 다재다능함은 고위험 산업에서 필수 불가결하게 만듭니다.

- 석유화학 및 석유/가스: 밸브, 펌프 샤프트 및 반응기 내부 부품에 사용되어 산성 가스 및 염화물 부식에 저항합니다.

- 화학 처리: 황산, 염산 및 아세트산이 있는 환경에서 교반기 및 열교환기 구성 요소에 이상적입니다.

- 제약 및 식품 가공: 부식 저항 및 쉬운 세척이 필요한 장비에 대한 위생 표준을 충족합니다.

- 항공 우주 및 에너지: 터빈 부품 및 원자력 반응기 구성 요소로 제작되어 극한의 온도와 압력을 견딥니다.

품질 보증 및 포장

각 바에는 재료 등급, 열 코드, 제조업체 기호 및 표준 지정을 영구적으로 표시하여 추적성을 보장합니다. 포장에는 운송 중 오염을 방지하기 위한 방수 종이 및 플라스틱 호일 포장이 포함되며, 대량 주문의 경우 맞춤형 상자 포장이 가능합니다. 최소 주문 수량은 10kg부터 시작하며, 소량 및 대량 요구 사항을 모두 지원하기 위해 월 500톤의 공급 능력을 갖추고 있습니다.

가혹한 환경에서 글로벌 표준 준수 및 입증된 성능을 바탕으로 Hastelloy C276 밝게 연마된 원형 바는 재료 고장이 선택 사항이 아닌 곳에서 신뢰성을 제공합니다. 화학 처리 장비 또는 항공 우주 부품에 관계없이 이러한 바는 정밀 엔지니어링과 뛰어난 내구성을 결합합니다.

![]()

![]()

![]()

![]()

추천된 제품