All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

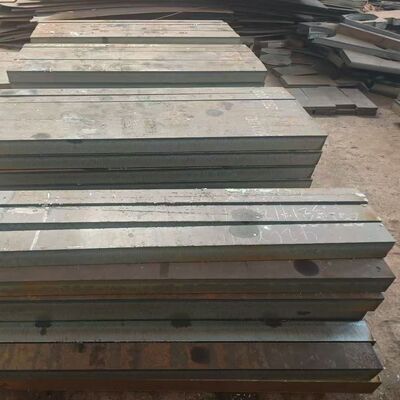

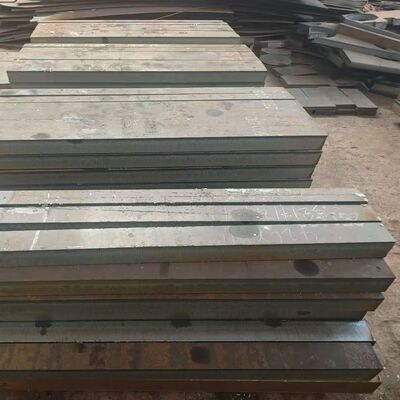

30CrMnSiA Quenched and Tempered Alloy Steel Plate for High-Performance Mechanical Components

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL BENSTEEL HBIS XINGCHENG |

| Certification | ISO 9001 |

| Model Number | 30CrMnSiA |

| Minimum Order Quantity | 10 kgs |

| Price | 540 - 890 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Product Details

| Products | 30CrMnSiA | Thickness | 10.0 - 200.0mm |

|---|---|---|---|

| Width | 1000-2200mm | Length | 2000-12000mm |

| Standard | ASTM EN GB | Other Material | Carbon Steel, Alloy Steel, Stainless Steel |

| Brand | BAOSTEEL XINYU XINGCHENG HBIS | Service | Cutting |

Product Description

Products Specification

| Product Name | 30CrMnSiA Alloy Steel Plate |

| Thickness | 10mm~200mm |

| Width | 1000~3000mm,common width is 1250mm,1500mm,2000mm,2200mm |

| Length | 1000~12000mm,can as your request cut |

| Surface | Clean,finished, blasting and painting or as your request |

| Delivery | Hot Rolled, Controlled Rolling,Normalizing,Annealing, Tempering,Quanching, Q+T |

| Packing | Steel Strapping,fixing in the Container,can customize |

| Thickness tolerance | ±0.3mm |

| Application | It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts. |

30CrMnSiA Quenched and Tempered Alloy Steel Plate for High-Performance Mechanical Components

Engineered Strength for Demanding Mechanical Systems

30CrMnSiA quenched and tempered (Q&T) alloy steel plate is a premium-grade, medium-carbon structural steel specifically heat-treated to deliver an exceptional balance of high strength, impact toughness, and fatigue resistance. Designed for mission-critical mechanical components in aerospace, defense, heavy machinery, oil & gas, and automotive sectors, this material excels where reliability under dynamic loads, shock, or wear is non-negotiable.

Our 30CrMnSiA Q&T plates are manufactured to GB/T 11251-2009 and GJB 2150A-2005 standards, then subjected to a precise quenching and tempering cycle to achieve uniform mechanical properties across thicknesses from 10 mm to 200 mm. Each plate is fully traceable, ultrasonically inspectable, and available with custom dimensions, surface finishes, and certified documentation—ensuring seamless integration into high-performance engineering workflows.

Why Choose Quenched & Tempered 30CrMnSiA?

Unlike as-rolled or normalized steel, Q&T 30CrMnSiA offers:

- Tensile strength up to 1275 MPa – ideal for weight-sensitive, high-load applications

- Superior fatigue life – critical for rotating or cyclically stressed parts

- Enhanced wear resistance – due to hardened microstructure and Cr/Mn alloying

- Controlled hardness (24–32 HRC) – balances machinability and durability

- Excellent low-temperature toughness – impact energy ≥88 J at –40°C (premium grade)

This makes it a top choice for gears, shafts, axles, landing gear, hydraulic rods, and other components that demand long service life under extreme conditions.

Chemical Composition (GB/T 11251 Standard)

| Element | Content (%) | Metallurgical Role |

|---|---|---|

| Carbon (C) | 0.28 – 0.34 | Enables martensite formation during quenching |

| Silicon (Si) | 0.90 – 1.20 | Strengthens ferrite; improves oxidation resistance |

| Manganese (Mn) | 0.80 – 1.10 | Enhances hardenability and hot ductility |

| Chromium (Cr) | 0.80 – 1.10 | Increases hardenability, wear resistance, and temper stability |

| Sulfur (S) | ≤ 0.025 | Minimized to avoid hot shortness |

| Phosphorus (P) | ≤ 0.025 | Controlled to prevent cold brittleness |

| Residuals (Ni, Cu, etc.) | ≤ 0.30 total | Kept low for weldability and purity |

The “A” suffix denotes higher purity than standard 30CrMnSi—essential for safety-critical parts.

Mechanical Properties After Quenching & Tempering

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength (Rm) | 1080 – 1275 MPa | GB/T 228.1 |

| Yield Strength (Rp0.2) | ≥ 835 MPa | GB/T 228.1 |

| Elongation (A5) | ≥ 10% | GB/T 228.1 |

| Reduction of Area (Z) | ≥ 45% | GB/T 228.1 |

| Impact Energy (20°C) | ≥ 39 J | GB/T 229 |

| Impact Energy (–40°C) | ≥ 88 J (premium grade) | GB/T 229 |

| Hardness | 24 – 32 HRC | ISO 6508 / GB/T 230.1 |

Note: Properties are optimized for plates ≤100 mm thick. For sections >150 mm, slight reductions in through-thickness hardness may occur but remain within specification.

Recommended Heat Treatment Cycle

To achieve the above properties, the following industrial-standard Q&T process is applied:

- Austenitizing: 860–880°C (soak time based on thickness)

- Quenching: Oil quench (preferred for reduced distortion vs. water)

- Tempering: 500–600°C (adjust based on target hardness/strength)

- Cooling: Air cool to room temperature

⚠️ Avoid tempering between 250–400°C to prevent temper brittleness.

Available Dimensions & Tolerances

| Parameter | Range |

|---|---|

| Thickness | 10 mm – 200 mm |

| Width | 1000 – 3000 mm (custom up to 3500 mm) |

| Length | 2000 – 12,000 mm |

| Thickness Tolerance | ±0.5 mm (10–50 mm); ±1.0 mm (50–100 mm); ±2.0 mm (>100 mm) per GB/T 709 |

| Flatness | ≤ 4 mm/m (standard); ≤ 2 mm/m (with leveling) |

| Surface Finish | Black scale (standard); shot-blasted, pickled, or oiled (optional) |

Typical High-Performance Applications

| Industry | Components |

|---|---|

| Aerospace | Landing gear struts, wing fittings, engine mounts |

| Defense | Armored vehicle frames, weapon system brackets, turret supports |

| Automotive & Motorsport | Crankshafts, connecting rods, transmission gears |

| Heavy Machinery | Excavator pins, hydraulic cylinders, gear blanks |

| Oil & Gas | Drill collars, downhole tools, high-pressure valve bodies |

| Rail & Transportation | Axles, couplers, suspension arms |

30CrMnSiA Q&T often serves as a cost-effective alternative to more expensive alloys like 4340 or 300M when ultra-high fracture toughness isn’t required.

Value-Added Services

We support your production chain with end-to-end solutions:

- Precision Cutting: Waterjet (up to 200 mm), plasma, or laser per CAD files

- Machining Prep: Edge beveling, hole drilling, chamfering

- Ultrasonic Testing (UT): Full-volume inspection per ASTM A578 Grade B/C

- Certification: EN 10204 3.1 Mill Test Reports, chemical & mechanical data

- Packaging: Export-ready bundling with anti-rust protection and heat-number marking

Quality & Compliance

- ✅ ISO 9001:2015 certified manufacturing

- ✅ Melt traceability from electric arc furnace (EAF) + LF + VD refining

- ✅ Optional third-party inspection (SGS, BV, TÜV)

- ✅ Documentation compliant with ASME, PED, and military procurement requirements

Global Supply with Technical Support

With decades of experience supplying Q&T alloy steels worldwide, we offer:

- Competitive pricing with mill-direct access

- Lead times of 10–25 days depending on size and quantity

- FOB or DDP shipping from major Chinese ports (Shanghai, Tianjin, Qingdao)

- Engineering support for material selection, welding procedures, and heat treatment validation

30CrMnSiA quenched and tempered plate, Q&T alloy steel plate 10-200mm, high-strength mechanical steel, GB/T 11251 Q&T steel, 30CrMnSiA for gears and shafts, wear-resistant Q&T plate, China 30CrMnSiA supplier, aerospace-grade alloy steel plate, impact-toughened structural steel, custom-cut Q&T steel for heavy machinery.

![]()

![]()

![]()

![]()

Recommended Products