-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

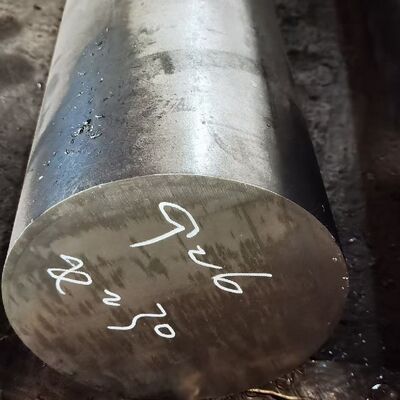

ASTM A743 CA6NM Equivalent 1.4418 Stainless Steel Round Bar – Quenched & Tempered for Turbine Shafts & Propellers

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products Name | 1.4418 Stainless Steel Bar | Diameter | 10 - 350mm |

|---|---|---|---|

| Length | 6m Or Cutting Any Length As Request | Surface | Black Or Polishing |

| Service | Cutting | Standard | ASTM DIN GB EN |

| Other Products | Round Bar, Square Bar, Flat Bar.etc | Technique | Hot Rolled |

ASTM A743 CA6NM Equivalent 1.4418 Stainless Steel Round Bar – Quenched & Tempered for Turbine Shafts & Propellers

Products Specification

| Products Name | 1.4418 Stainless Steel Round Bar |

| Grade |

303,303Cu,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800,800H,825,926.etc |

| Products Diameter Range | φ3mm - φ350mm |

| Length | 6m/pcs or cutting any length as request |

| Surface | Pickling finishing, bright finishing |

| Standard | ASTM JIS,GB,DIN EN |

| Service | Cutting |

| Other Shape | Square , Flat, Hexagonal, Round.etc |

| Loading Port | Shanghai Port |

| MOQ | 50 kgs |

Overview

1.4418 stainless steel round bar is a premium martensitic stainless steel specifically engineered for demanding applications such as turbine shafts, marine propellers, valves, and pump components. This grade is the European equivalent (EN 1.4418) to the ASTM A743 CA6NM standard, offering an exceptional combination of high strength, excellent corrosion resistance, good toughness, and superior castability/weldability. Supplied in a quenched and tempered condition, it provides reliable performance in corrosive and high-stress environments.

This material is particularly favored in industries like hydroelectric power, shipbuilding, chemical processing, and oil & gas due to its ability to withstand cavitation erosion, pitting, and corrosion fatigue. The following sections provide a detailed breakdown of its specifications, properties, and advantages.

Material Standards & Specifications

1.4418 / CA6NM conforms to several international standards, ensuring quality and consistency across global supply chains.

| Standard Type | Standard Designation | Grade/Analysis |

|---|---|---|

| ASTM Standard | ASTM A743 / A744 | CA6NM |

| European Standard | EN 10088-3 / EN 10250-4 | 1.4418 |

| UNS Number | UNS J91540 | - |

| Common Names | - | 13Cr-4Ni Stainless |

Chemical Composition

The balanced chemical composition is key to its performance. It contains lower carbon than traditional martensitic steels to enhance weldability, while chromium provides corrosion resistance, and nickel improves toughness and strength.

| Element | Content (%) - Typical | Content (%) - Standard Range |

|---|---|---|

| Carbon (C) | 0.05 max | ≤ 0.06 |

| Chromium (Cr) | 12.5 | 11.5 - 14.0 |

| Nickel (Ni) | 4.0 | 3.5 - 4.5 |

| Molybdenum (Mo) | 0.6 | 0.4 - 1.0 |

| Manganese (Mn) | 0.8 | ≤ 1.0 |

| Silicon (Si) | 0.6 | ≤ 1.0 |

| Phosphorus (P) | 0.035 max | ≤ 0.04 |

| Sulfur (S) | 0.015 max | ≤ 0.03 |

| Iron (Fe) | Balance | Balance |

Mechanical Properties (Quenched & Tempered Condition)

Heat treatment (quenching and tempering) is critical to achieving the desired mechanical properties. Typical properties for round bars are as follows:

| Property | Typical Value | Remarks / Test Standard |

|---|---|---|

| Tensile Strength (Rm) | 850 - 1050 MPa | Adjustable via tempering |

| Yield Strength (Rp0.2) | ≥ 620 MPa | Minimum 0.2% proof stress |

| Elongation (A5) | ≥ 15% | On 5.65√S₀ gauge length |

| Reduction of Area (Z) | ≥ 45% | - |

| Hardness | 250 - 320 HB | Brinell Hardness |

| Impact Toughness (KV) | ≥ 50 J at 20°C | Charpy V-notch, transverse |

| Impact Toughness (KV) | ≥ 27 J at -20°C | Suitable for sub-zero temps |

Heat Treatment (Quenching & Tempering)

The standard heat treatment process involves:

-

Austenitizing (Hardening): Heating to 1000-1050°C, followed by oil or air quenching to form martensite.

-

Tempering: Reheating to 550-650°C (double tempering is often used), then air cooling. This relieves stresses, improves toughness, and adjusts final strength/hardness.

Post-weld heat treatment (PWHT) is generally recommended to restore properties in the heat-affected zone (HAZ).

Physical Properties

| Property | Value / Description |

|---|---|

| Density | 7.7 - 7.8 g/cm³ |

| Melting Range | ~ 1450 °C |

| Thermal Conductivity | ~ 25 W/m·K at 20°C |

| Specific Heat Capacity | ~ 460 J/kg·K at 20°C |

| Coefficient of Thermal Expansion | ~ 10.5 x 10⁻⁶ /K (20-100°C) |

| Electrical Resistivity | ~ 0.75 µΩ·m |

| Magnetic Properties | Magnetic (due to martensitic structure) |

Key Features & Advantages

-

Excellent Corrosion Resistance: Superior to standard martensitic 13% Cr steels due to added nickel and molybdenum. Resists corrosion in freshwater, seawater, mild acidic, and alkaline environments. Offers good resistance to pitting and crevice corrosion.

-

High Strength & Toughness: The quenched and tempered martensitic structure provides high tensile and yield strength combined with good impact toughness, even at moderately low temperatures.

-

Good Cavitation Erosion Resistance: This makes it a prime choice for hydro turbine components, propeller blades, and pump impellers operating in high-velocity water flows.

-

Superior Weldability & Castability: Low carbon content minimizes the risk of cold cracking. It can be welded using common methods (SMAW, GTAW, GMAW) with matching or over-alloyed filler metals, and post-weld heat treatment is straightforward.

-

Machinability: In the annealed or tempered condition, it offers fair machinability (approximately 60% compared to 1% C steel). Using appropriate tools and coolants is recommended for optimal results.

-

Versatility: Available in various forms – round bars, forgings, castings, plates – making it suitable for fabricated and machined components.

Typical Applications

1.4418 / CA6NM round bars are extensively used in the following critical components:

-

Hydro & Steam Turbines: Shafts, runners, blades, and wear rings.

-

Marine & Shipbuilding: Propeller shafts, marine propellers, rudder stocks, and deck machinery components.

-

Pumps & Valves: Shafts, impellers, valve bodies, and fittings for corrosive service.

-

Oil & Gas: Components for Christmas trees, wellhead equipment, and pumps handling mildly corrosive fluids.

-

General Engineering: High-strength fasteners, gears, and machine parts requiring corrosion resistance.

Available Specifications (Round Bar)

| Parameter | Typical Availability |

|---|---|

| Diameter Range | 20 mm to 500 mm (and larger via forging) |

| Condition | Quenched & Tempered, Black, Peeled, or Polished |

| Length | Random lengths, cut to size, or long bars up to 6m+ |

| Certification | Mill Test Certificate 3.1 / 3.2 per EN 10204 |

Quality Assurance & Testing

Supplied material is subject to rigorous quality checks, including:

-

Chemical analysis via spectrometry.

-

Mechanical testing (tensile, impact, hardness).

-

Non-destructive testing (Ultrasonic Testing - UT, Dye Penetrant Testing - PT, or Magnetic Particle Testing - MT) available upon request.

-

Macro/Microstructure examination.

-

All documentation (MTC) is traceable to the heat/lot number.

Conclusion

ASTM A743 CA6NM equivalent 1.4418 stainless steel round bar in quenched and tempered condition represents a high-performance material solution for engineering challenges where strength, toughness, and corrosion resistance are paramount. Its well-balanced chemistry and controlled heat treatment make it a reliable and durable choice for critical rotating components like turbine shafts and propellers, ensuring long service life and reduced maintenance costs in aggressive operating environments.

![]()

![]()

![]()

![]()