Custom Cutting C276 Nickel Alloy Round Bar Hastelloy UNS N10276 Rod in Short Pieces

More Specification Informations

| Products Name |

Hastelloy C276 Round Bar / Rod |

| Diameter |

6.0 - 350mm |

| Length |

custom cutting any length as request |

| Surface |

Black , bright |

| Brand |

DELTA |

| Service |

cutting, Polishing |

| MOQ |

2 Kgs |

| Other Type |

round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing |

waterproof paper and wooden pallets, wooden box |

| Loading Port |

Shanghai Port |

| Price term |

EXW,FOB,CIF,CFR |

| Deliver time |

within 12 days |

Regular Diameter of Hastelloy C276 Round Bar in Stock

| 6mm |

8mm |

9mm |

10mm |

12mm |

14mm |

| 15mm |

16mm |

18mm |

19mm |

20mm |

22mm |

| 25mm |

28mm |

30mm |

32mm |

35mm |

38mm |

| 40mm |

42mm |

45mm |

48mm |

50mm |

55mm |

| 60mm |

65mm |

70mm |

75mm |

80mm |

85mm |

| 90mm |

95mm |

100mm |

105mm |

110mm |

115mm |

| 120mm |

125mm |

130mm |

140mm |

150mm |

160mm |

| 170mm |

180mm |

190mm |

200mm |

210mm |

220mm |

| 230mm |

240mm |

250mm |

260mm |

270mm |

280mm |

| 290mm |

300mm |

310mm |

320mm |

330mm |

340mm |

Hastelloy UNS N10276 (commonly known as C276 nickel alloy) is a premium nickel-molybdenum-chromium alloy renowned for its exceptional corrosion resistance, high-temperature stability, and mechanical strength. It is widely recognized as a top choice for demanding industrial applications where exposure to aggressive chemicals, extreme temperatures, or harsh environments is unavoidable. Below is a detailed overview of C276 round bars, including their key types, processing methods, custom cutting services, product standards, and typical applications.

C276 round bars are available in two primary finishes to suit diverse processing and application needs: Hot-Rolled Bars and Bright Bars. Each type features distinct characteristics tailored to specific industrial requirements.

The manufacturing of C276 round bars involves strict, industry-proven processes to ensure consistency in quality and performance. The core steps include:

- Alloy Melting & Casting: High-purity nickel, molybdenum, chromium, and trace elements (e.g., tungsten, iron) are melted in electric arc furnaces or vacuum induction furnaces (VIF) to avoid contamination. The molten alloy is then cast into ingots or billets.

- Hot Rolling: For hot-rolled bars, the cast billets are heated to high temperatures (typically 1100–1200°C) and passed through a series of rolling mills to reduce diameter and form the round bar shape. This process improves the alloy’s grain structure and mechanical strength.

- Cold Finishing (for Bright Bars): After hot rolling, bright bars undergo additional cold-working processes—such as cold drawing, cold rolling, or centerless grinding—to achieve a smooth surface and tight dimensional tolerance. Cold finishing also increases the bar’s hardness and surface quality.

- Heat Treatment: Both hot-rolled and bright bars may undergo solution annealing (heating to 1150–1200°C, followed by rapid quenching) to dissolve precipitated phases, restore corrosion resistance, and optimize mechanical properties.

To meet the diverse needs of end-users (e.g., small-batch production, prototype development, or on-site assembly), we offer precision custom cutting services for C276 round bars into short pieces. Key features of our cutting service include:

- Flexible Length Options: Cut-to-order lengths ranging from 50mm to 2000mm (or as per customer specifications), eliminating material waste and reducing post-processing costs.

- High-Precision Cutting Technologies:

- CNC Sawing: Ideal for large-diameter bars (≥50mm), ensuring straight cuts with minimal burrs and length tolerance of ±0.5mm.

- Laser Cutting: Suitable for small-diameter bars (≤30mm), providing ultra-precise cuts (tolerance ±0.1mm) and a smooth cut surface.

- Waterjet Cutting: Used for bars requiring no thermal distortion (critical for corrosion-sensitive applications), offering clean cuts without altering the alloy’s microstructure.

- Deburring & Surface Treatment: Post-cutting deburring (mechanical or chemical) to remove sharp edges, and optional surface cleaning (e.g., pickling, passivation) to enhance corrosion resistance.

C276 round bars adhere to global industry standards to ensure reliability and compatibility with international projects. Key applicable standards include:

- ASTM International: ASTM B574 (Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloy (UNS N10276) Rod and Bar)

- ASME: ASME SB574 (equivalent to ASTM B574, for pressure vessel and boiler applications)

- ISO: ISO 9723 (Nickel and nickel alloys—Rod, bar, and wire for general engineering purposes)

- DIN: DIN EN 10095 (Nickel and nickel alloys—Rod, bar, and wire)

All C276 round bars undergo rigorous quality inspections, including:

- Chemical composition analysis (via X-ray fluorescence or optical emission spectroscopy) to confirm compliance with UNS N10276 standards.

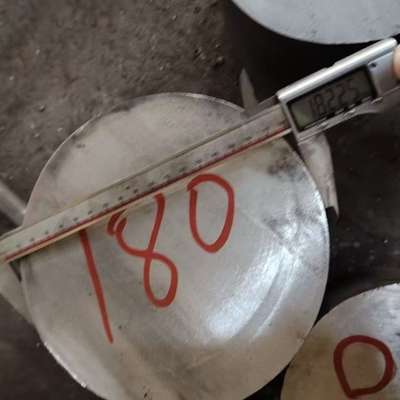

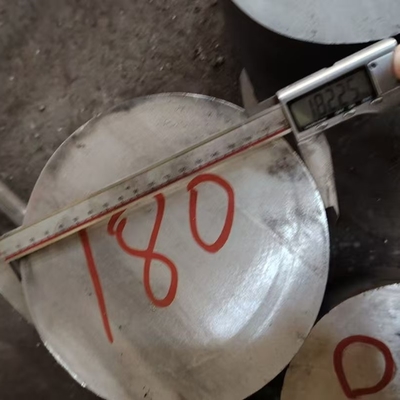

- Dimensional inspection (using calipers, micrometers, or coordinate measuring machines (CMM)) to verify diameter and length tolerance.

- Mechanical testing (tensile strength, yield strength, elongation) and hardness testing (Brinell, Rockwell).

- Corrosion resistance testing (e.g., salt spray testing, immersion testing in acidic/alkaline solutions) for critical applications.

Thanks to its outstanding corrosion resistance (especially to pitting, crevice corrosion, and stress corrosion cracking in harsh media like sulfuric acid, hydrochloric acid, and seawater) and high-temperature performance (stable up to 1093°C), C276 round bars are widely used in:

- Chemical Processing: Reactors, heat exchangers, valves, pumps, and piping components for handling acids, solvents, and corrosive intermediates.

- Oil & Gas: Downhole tools, wellhead components, and offshore platform parts (resistant to sour gas, brine, and marine environments).

- Aerospace & Defense: Engine components, fuel system parts, and rocket nozzles (withstands high temperatures and oxidative environments).

- Pharmaceutical & Food Processing: Equipment for sterile manufacturing (e.g., mixing tanks, conveyor parts) due to its high purity and corrosion resistance to cleaning agents.

- Environmental Engineering: Flue gas desulfurization (FGD) systems, wastewater treatment equipment, and incinerator components (resistant to acidic flue gases and toxic chemicals).

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

![]()

![]()

![]()

![]()